Coke oven exit passageway identification brick and preparation method thereof

A technology for safe passage and marking, applied in clay products, other household appliances, applications, etc., can solve the problems of easy fading of the paint on the sidewalk on the stove top, easy fading of the interface of the safe passage on the stove top, hidden dangers to the safety of operators, etc. Economical use, high gloss, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of the coke oven safe passage marking brick as described in any one of the above, comprising the steps of:

[0043] S1: Prepare the glaze and the blank separately. When the components in the blank are mixed, use the ferromagnet to discharge the mechanical iron in each component; specifically, the preparation process of the glaze is as follows:

[0044] S11: Weighing feldspar, quartz, kaolin, stalactite, raw talc, zinc powder, titanium dioxide and zircon powder according to the weight ratio, and mixing the above raw materials;

[0045] S12: The mixed raw materials are ball milled to reach the standard use size; the mixed raw materials are ball milled for about 12 hours to form a mixed slurry, and half of the mixed slurry is poured out so that the fineness of the poured mixed slurry reaches 400 mesh , the other half of the mixed slurry continued to be ball-milled to make the fineness of the mixed slurry reach <5 μm, and finally the 400-mesh mixed slur...

Embodiment 1

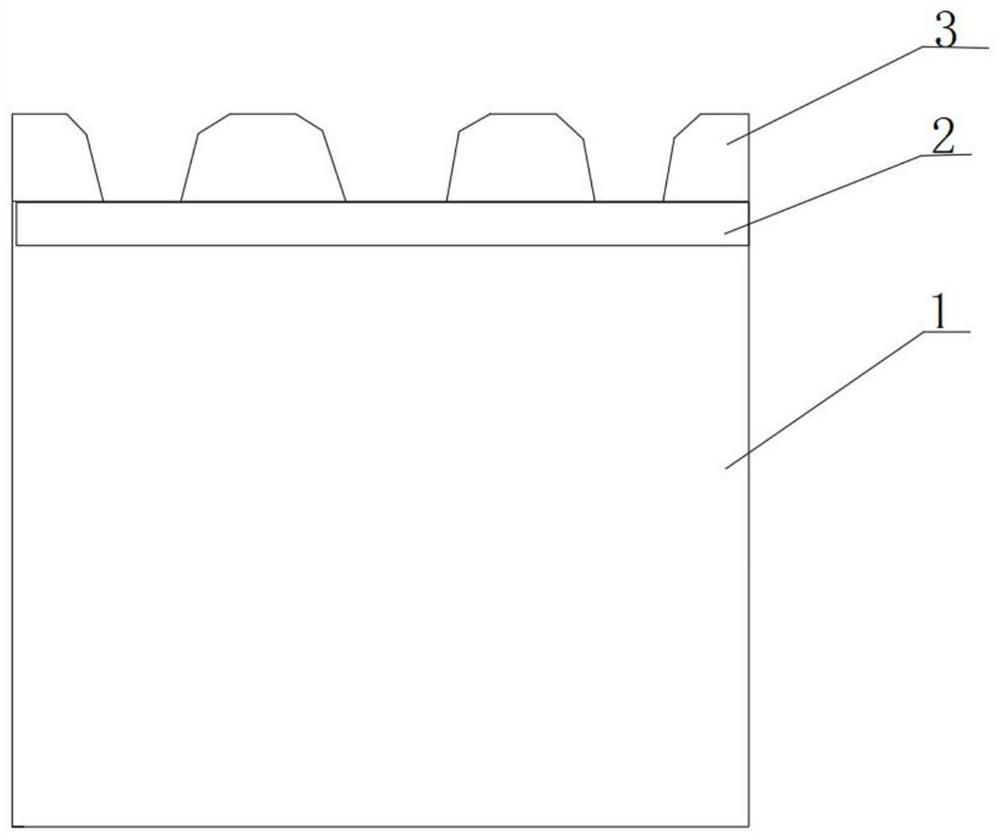

[0051] A coke oven safety channel marking brick, comprising a brick body 1, a glaze layer 2 is arranged on the surface of the brick body 1, and the glaze layer 2 includes raw materials in the following weight percentages: feldspar: 59%, quartz: 15%, kaolin: 1.5% , stalactite: 10%, raw talc: 9%, zircon powder: 3%, titanium dioxide: 1%, zinc powder: 0.02%, and the balance is impurities; wherein, the brick body 1 includes the following components in weight percentage: kaolin : 40%, coke gem: 9%, cylinder sand: 42%, potassium feldspar: 9%. The preparation method of this identification brick is as follows:

[0052] S1: Prepare the glaze and the blank separately. When the components in the blank are mixed, use the ferromagnet to discharge the mechanical iron in each component; specifically, the preparation process of the glaze is as follows:

[0053] S11: Weighing feldspar, quartz, kaolin, stalactite, raw talc, zinc powder, titanium dioxide and zircon powder according to the weight...

Embodiment 2

[0059] A coke oven safety channel marking brick, comprising a brick body 1, a glaze layer 2 is arranged on the surface of the brick body 1, and the glaze layer 2 includes the following raw materials in weight percentage: feldspar: 60%, quartz: 14%, kaolin: 1.5% , stalactite: 8%, raw talc: 12%, zircon powder: 3%, titanium dioxide: 1%, zinc powder: 0.02%, and the balance is impurities; wherein, the brick body 1 includes the following components in weight percentage: kaolin : 45%, coke gem: 10%, cylinder sand: 38%, potassium feldspar: 7%. The preparation method of this identification brick is as follows:

[0060] S1: Prepare the glaze and the blank separately. When the components in the blank are mixed, use the ferromagnet to discharge the mechanical iron in each component; specifically, the preparation process of the glaze is as follows:

[0061] S11: Weighing feldspar, quartz, kaolin, stalactite, raw talc, zinc powder, titanium dioxide and zircon powder according to the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com