Automatic gluing device

A glue sticking device and automatic technology, applied in the directions of transportation and packaging, object supply, winding strips, etc., can solve the problems of affecting the quality of glue sticking, reducing the tension of the tape, reducing the production efficiency, etc., to prevent foaming. Drive the movement of the tape, ensure the effect of glue sticking, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further described in conjunction with the following examples.

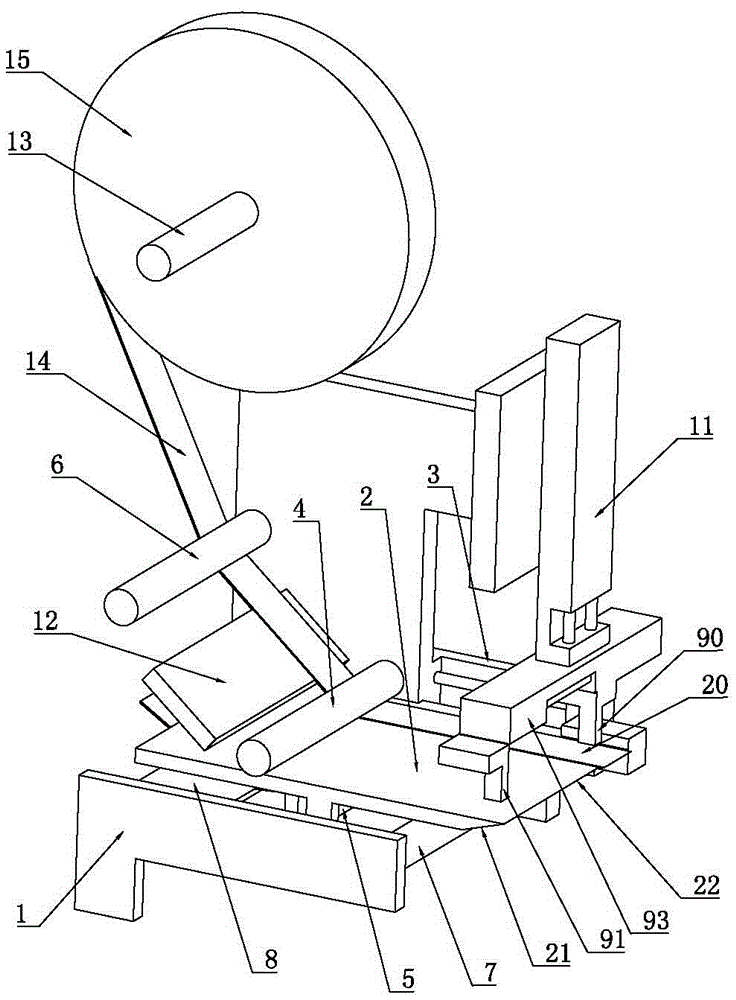

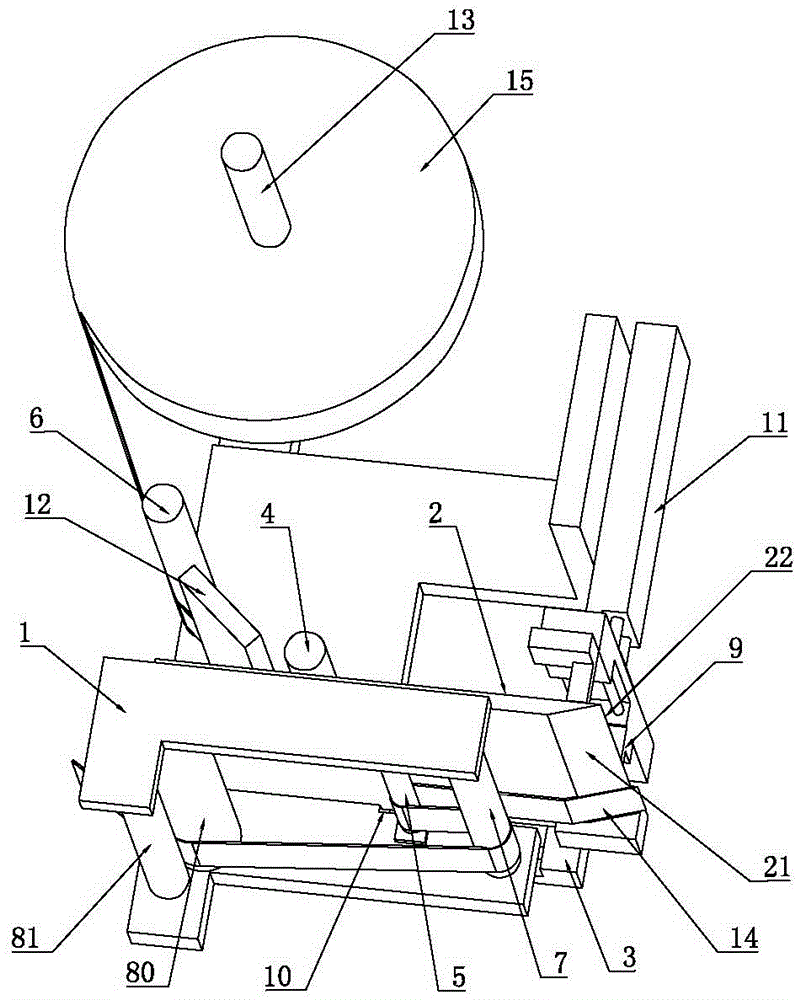

[0038] The specific embodiment of a kind of automatic gluing device of the present invention, as figure 1 and figure 2 As shown, it includes a frame 1, a reclaiming assembly and a reclaiming platform 2. The reclaiming platform 2 can move left and right relative to the frame under the drive of the first driving cylinder 3. The reclaiming assembly, the reclaiming platform 2, and the first drive Cylinders 3 are all located on the frame 1.

[0039] The top of the reclaiming platform 2 is provided with at least one first tensioning roller 4 for tensioning the tape 14, the first tensioning roller 4 is fixed on the frame 1, and the first tensioning roller 4 is close to the reclaiming platform 2, so that the adhesive tape 14 is flattened on the reclaiming platform 2, which facilitates retrieving of the retrieving components.

[0040] Further, a third tension roller 6 for tensioning the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com