Fracturing propping agent and preparation method thereof

A fracturing proppant and modifier technology, applied in the field of fracturing proppant, can solve problems such as agglomeration of fracturing proppant, and achieve the effect of high crushing resistance and preventing closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of the fracturing proppant provided by the present invention comprises curing the mixture containing the aggregate particles and the coating binder, wherein the coating binder is a hydrophilic resin composition, and the hydrophilic The preparation method of resin composition comprises:

[0014] The epoxy resin is first contacted with at least one modifier having at least one proton-donating group and at least one hydrophilic group under conditions such that the ring Part of the epoxy group in the epoxy resin reacts with the proton-providing group in the modifier, the proton-providing group is an amine group, and the hydrophilic group is selected from carboxyl and sulfonic acid groups ;as well as

[0015] The mixture obtained from the first contacting is subjected to a second contacting with at least one basic material under conditions sufficient to cause the acid to form a salt.

[0016] According to the present invention, the molecular structur...

Embodiment 1

[0058] (1) Dissolve 100g of epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-21, epoxy value 0.21mol / 100g) in 50g of toluene, and raise the temperature to 50°C with stirring, Then add 6.9g of p-aminobenzoic acid, stir and react at this temperature for 2 hours; then add 3.7g of triethylamine, continue the reaction for 1 hour, and remove the solvent with a rotary evaporator at a temperature of 60°C, thereby obtaining the present invention. hydrophilic resin composition.

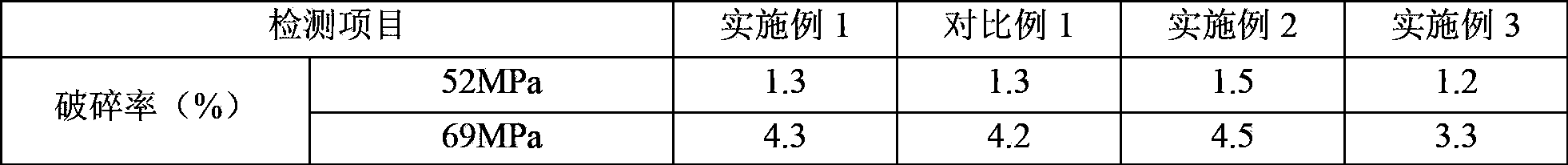

[0059] (2) Mix 100g of the hydrophilic resin composition obtained in step (1) with 2000g of raw sand (commercially purchased from Qingtongxia Jinshengyuan Proppant Co., Ltd., with a particle size of 30-50 mesh) and stir for 2 minutes, then add 25g of tetrahydrophthalic anhydride and 3g of diethylenetriamine were stirred at 180°C for 3 minutes, and then the temperature was lowered to room temperature (25°C), thereby obtaining a fracturing proppant. The fracture resistance p...

Embodiment 2

[0065] (1) Dissolve 100g of epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-54, epoxy value 0.54mol / 100g) in 50g of toluene, and raise the temperature to 50°C with stirring, Then add 10.3g of p-aminobenzoic acid, stir and react at this temperature for 2 hours; then add 10.7g of tri-n-propylamine, continue the reaction for 1 hour, and remove the solvent with a rotary evaporator at a temperature of 60°C to obtain The hydrophilic resin composition of the present invention.

[0066] (2) Mix 100g of the hydrophilic resin composition obtained in step (1) with 2000g of raw sand (commercially purchased from Qingtongxia Jinshengyuan Proppant Co., Ltd., with a particle size of 30-50) and stir for 2 minutes, then add 25g Diaminodiphenylmethane was stirred at 180°C for 3 minutes, and then the temperature was lowered to room temperature (25°C), thereby obtaining a fracturing proppant. The fracture resistance properties of the fracturing proppants are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| sphericity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com