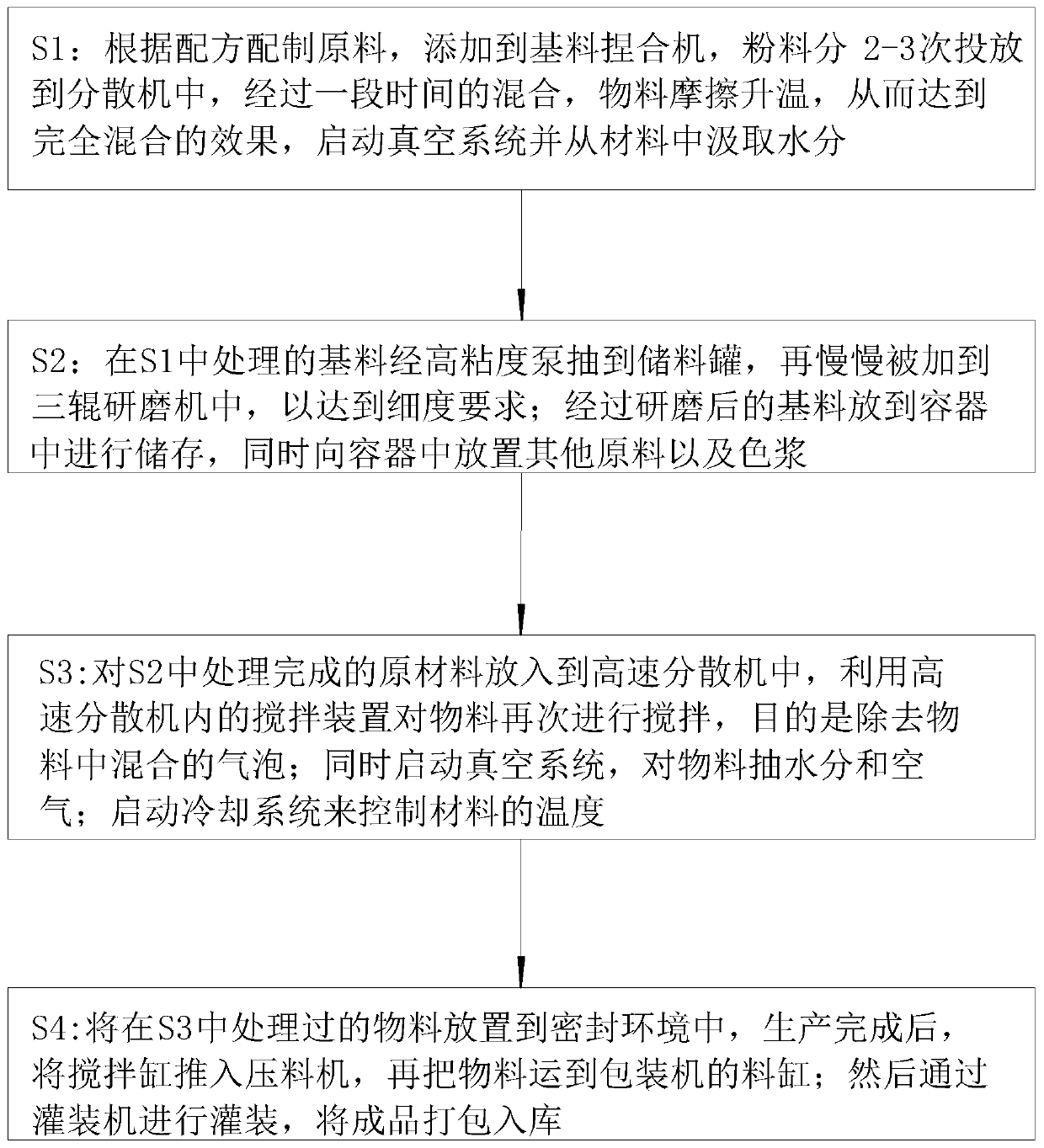

Sealant production method

A production method and sealant technology, applied in mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of low dispersion efficiency, slow movement speed, and air bubbles in the sealant, and achieve full and uniform stirring and reduced air bubble content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

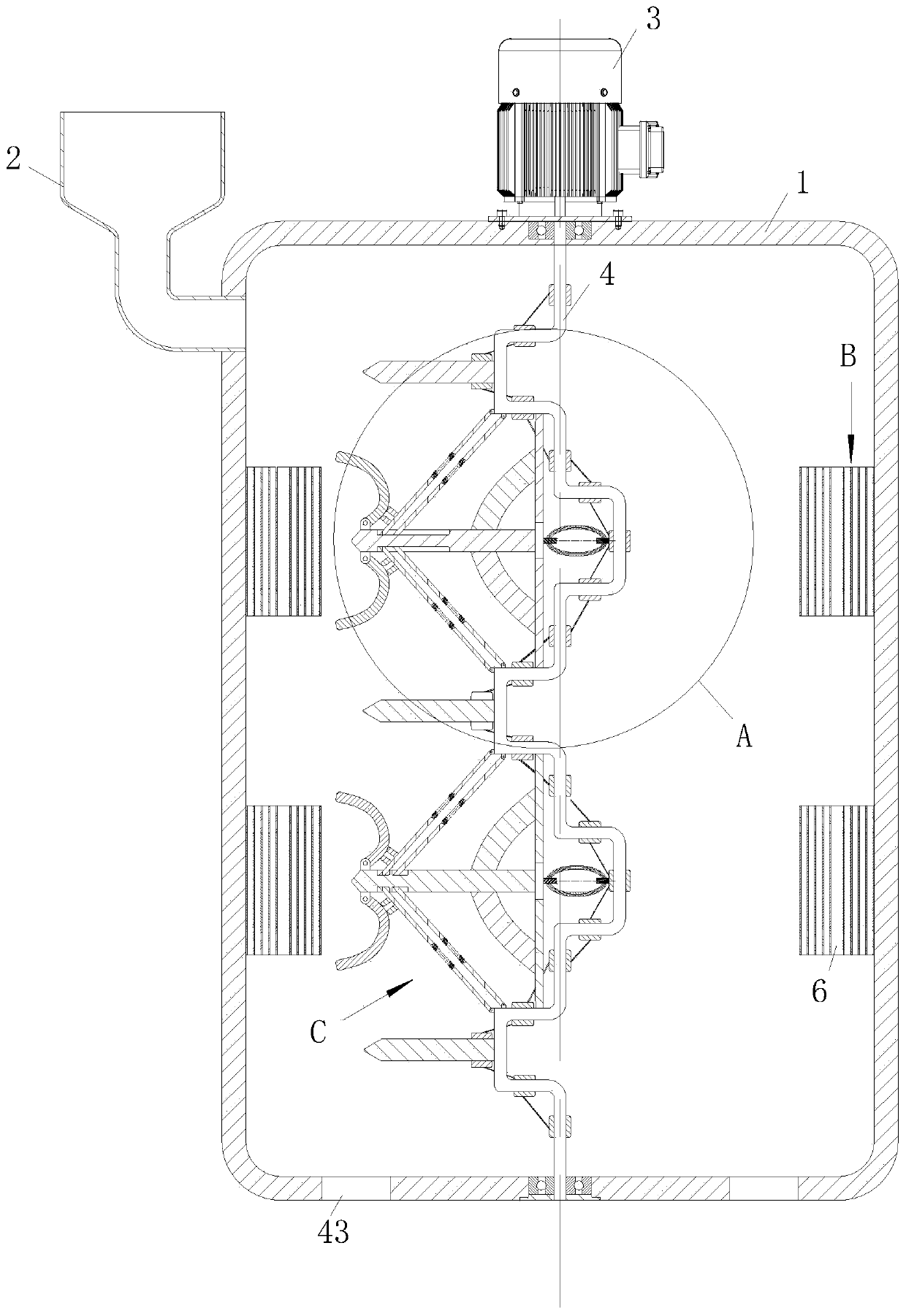

[0035] As an embodiment of the present invention, the arc-shaped push rod 56 is provided with a coiled plate 6 at a position corresponding to the box body 1, and the coiled plate 6 is fixedly connected to the inner wall of the box body 1, and both sides of the box body 1 are arranged symmetrically. There is a coiled plate 6; the blade 52 arranged on the bow-shaped connecting shaft 4 rotates under the drive of the bow-shaped connecting shaft 4 to drive the arc-shaped push rod 56 to turn over, and the arc-shaped push rod 56 will contact the coiled plate 6 arranged on the inner wall of the box body 1 , the arc-shaped push rod 56 will be in contact with both sides of the coiled plate 6 and tightened, and the arc-shaped push rod 56 will straighten the coiled plate 6 along with the rotation of the arc-shaped push rod 56, and the straightened coiled plate 6 will be in contact with Material contact, thereby enhancing the mixing strength of the material, making the material mixing more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com