Glass clarifier and glass preparation method

A clarifying agent and glass technology, applied in glass manufacturing equipment, glass furnace equipment, glass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] see figure 1 , the preparation method of the glass of an embodiment, comprises the steps:

[0034] Step S110: Mix the raw material mixture and the glass clarifier to obtain a batch material, melt the batch material at 1400°C-1520°C, and then raise the temperature to 1550°C-1620°C for clarification to obtain glass liquid.

[0035] Raw material mixtures are proportioned as required, and may be aluminosilicate mixtures, phosphate mixtures, and the like. As a glass clarifier, the glass clarifier mentioned above was used.

[0036] The mass ratio of the raw material mixture to the glass clarifying agent is 90.5-98.78:1.22-9.5.

[0037] The melting time is preferably 1 hour, and the clarifying time is preferably 2 hours.

[0038] Step S120: shaping the molten glass to obtain glass.

[0039] Preferably, the step of forming the molten glass is formed by a float method.

[0040] After the glass is prepared, a step of tempering the glass to obtain tempered glass is also inclu...

Embodiment 1

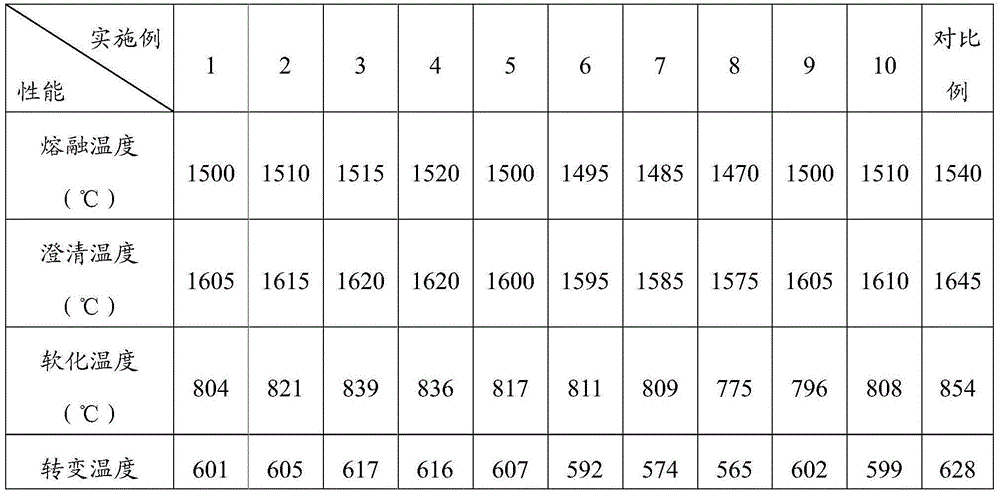

[0052] 1. Mix the raw material mixture and glass clarifier to obtain the batch material, put the batch material in an electric melting furnace, and keep it warm at 1500°C for 1 hour to melt the batch material; wherein, the raw material mixture includes quartz sand, Na 2 CO 3 , CaCO 3 、KNO 3 、K 2 CO 3 、NaNO 3 , MgO, Al 2 o 3 , zircon sand and TiO 2 ; Glass fining agents including NH 4 NO 3 、Na 2 SO 4 , CeO 2 and SnO 2 , NH 4 NO 3 、Na 2 SO 4 , CeO 2 and SnO 2 The mass ratio of the raw material mixture and the glass clarifier is 97.15:2.85.

[0053] 2. Raise the temperature of the molten batch to 1605°C for clarification for 2 hours to obtain molten glass;

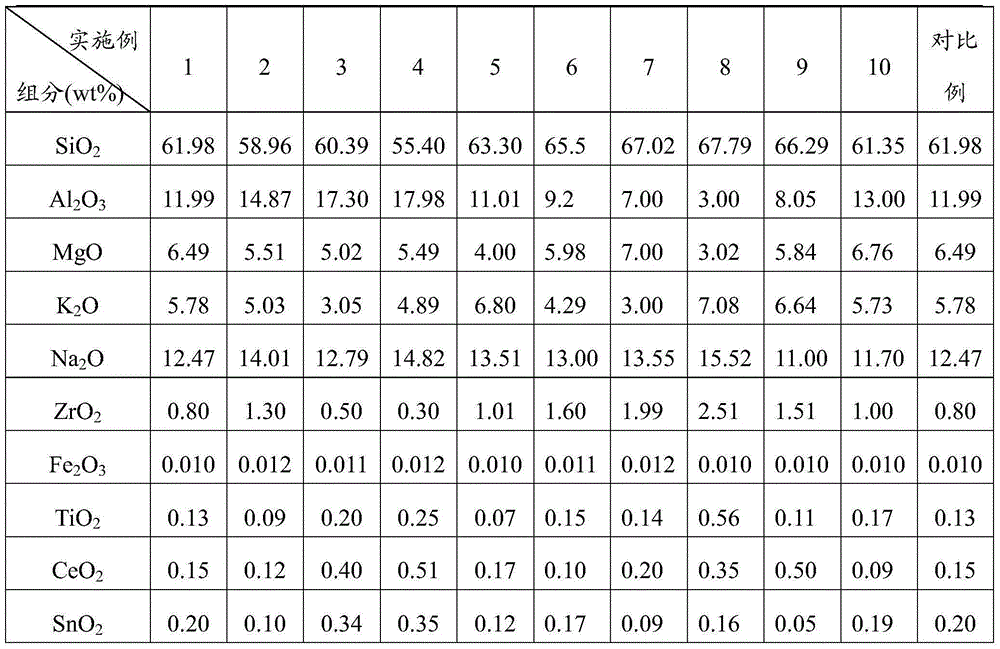

[0054] 3. The molten glass is formed by the float method to obtain zirconium aluminosilicate glass. The components of the zirconium aluminosilicate glass are shown in Table 1;

[0055] 4. Heat the zirconium aluminosilicate glass at 300°C for 30 minutes, then place it in a potassium nitrate melt at 420°C f...

Embodiment 2

[0057] 1. Mix the raw material mixture and glass clarifier to obtain the batch material, put the batch material in an electric melting furnace, and keep it warm at 1510°C for 1 hour to melt the batch material; wherein, the raw material mixture includes quartz sand, Na 2 CO 3 , CaCO 3 、KNO 3 、K 2 CO 3 、NaNO 3 , MgO, Al 2 o 3 , zircon sand and TiO 2 ; Glass fining agents including NH 4 NO 3 、Na 2 SO 4 , CeO 2 and SnO 2 , NH 4 NO 3 、Na 2 SO 4 , CeO 2 and SnO 2 The mass ratio of the raw material mixture and the glass clarifier is 2.0:3.0:0.12:0.10; the mass ratio of the raw material mixture and the glass clarifier is 94.78:5.22.

[0058] 2. Raise the temperature of the melted batch to 1615°C for clarification for 2 hours to obtain molten glass;

[0059] 3. The molten glass is formed by the float method to obtain zirconium aluminosilicate glass. The components of the zirconium aluminosilicate glass are shown in Table 1;

[0060] 4. Heat the zirconium aluminosil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com