Plastic casing structure provided with protective circuit, as well as forming die and manufacture method thereof

A technology of plastic shell and circuit protection, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problems of high production cost and difficult to achieve, improve the yield, reduce the loss of defective products, and facilitate rapid The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

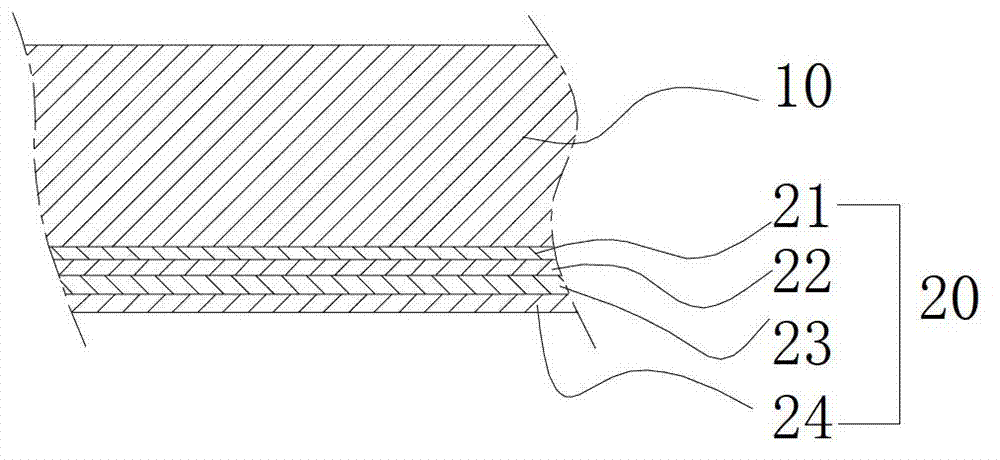

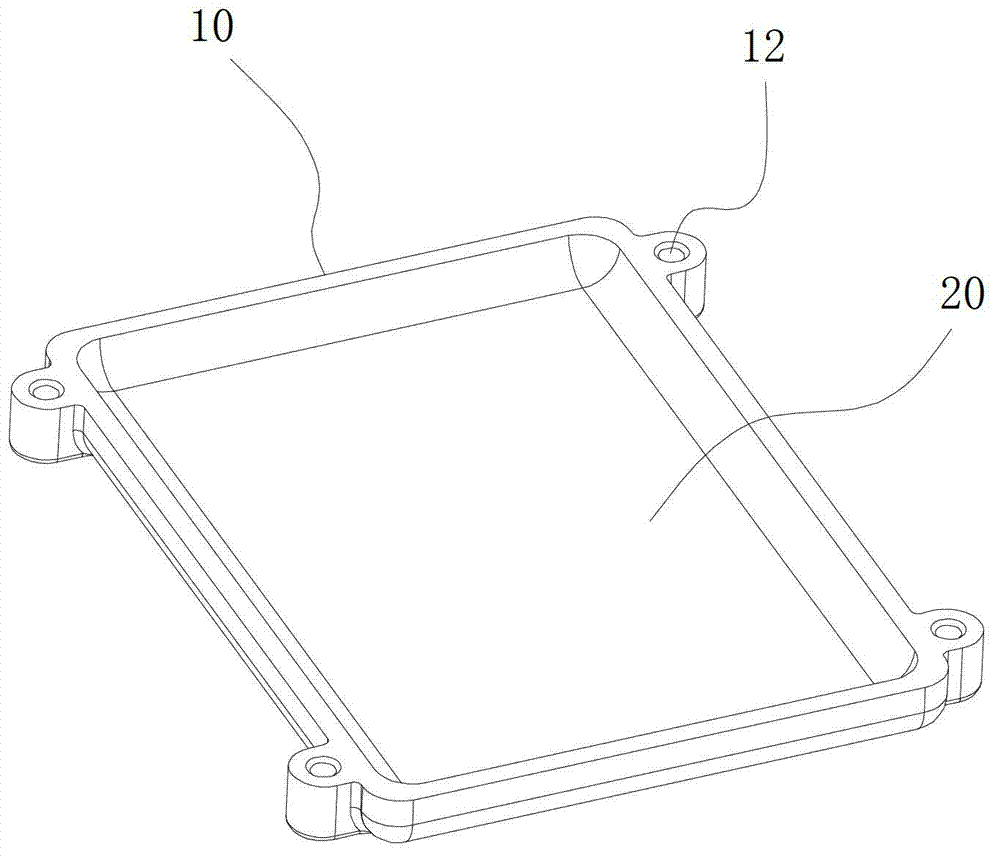

[0039] Such as Figure 1 to Figure 5 In the shown embodiment, the present invention has a plastic shell structure for protecting the circuit, including a plastic shell body 10, and a film layer 20 is provided on the inner side of the plastic shell body 10, and the film layer 20 includes an adhesive layer 21, a base layer 22, The winding layer 23 and the insulating layer 24; the glue layer 21 are connected with the plastic shell body 10 during injection molding.

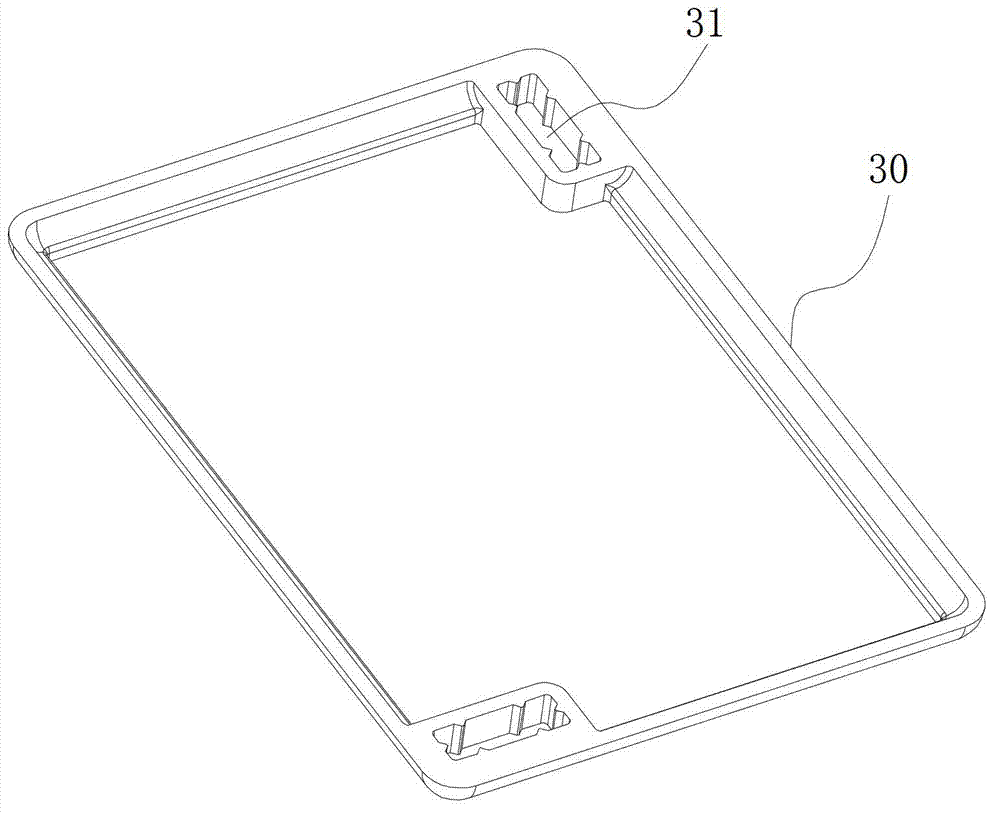

[0040] The winding layer 23 is provided with two connection ports 231 , and the winding layer 23 is provided with two protection wires, and the two ends of the protection wires are provided at the connection ports 231 . Two protective wires are arranged on the winding layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com