Quick hardening type light wallboard

A light-weight wallboard and fast-hardening technology, which is applied in the field of building materials, can solve the problems of long setting time, heavy weight, and low early strength, and achieve the effects of shortening molding processing time, improving construction performance, and high early strength

Active Publication Date: 2017-06-13

达州天创新材料有限公司

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the wallboard materials on the market are mainly silicate, which has the disadvantages of long setting time, low early strength, and heavy weight, which does not meet people's needs for lightweight wallboards.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

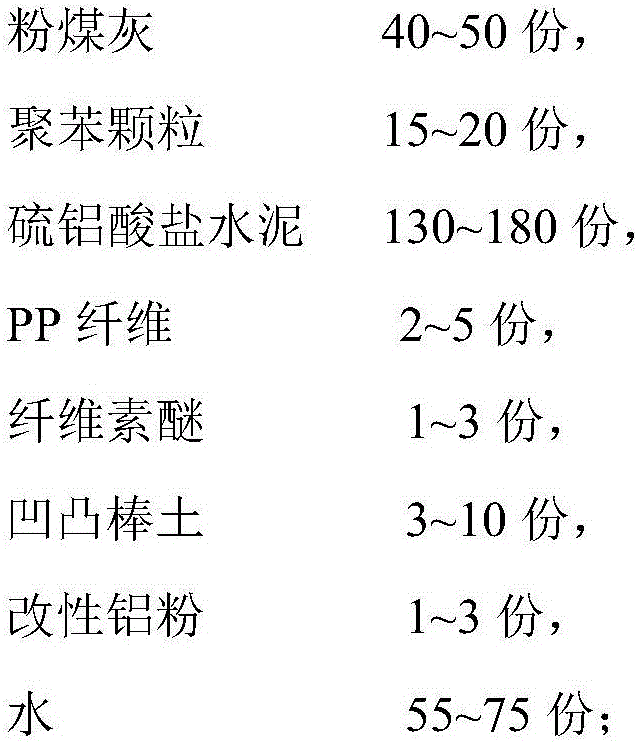

[0027] A fast-hardening lightweight wallboard, comprising the following raw materials in parts by weight:

[0028]

Embodiment 2

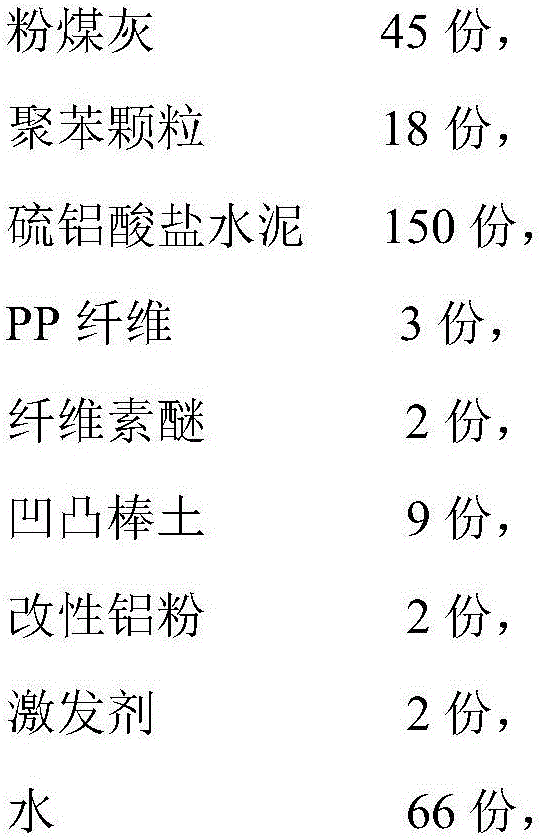

[0030] A fast-hardening lightweight wallboard, comprising the following raw materials in parts by weight:

[0031]

Embodiment 3

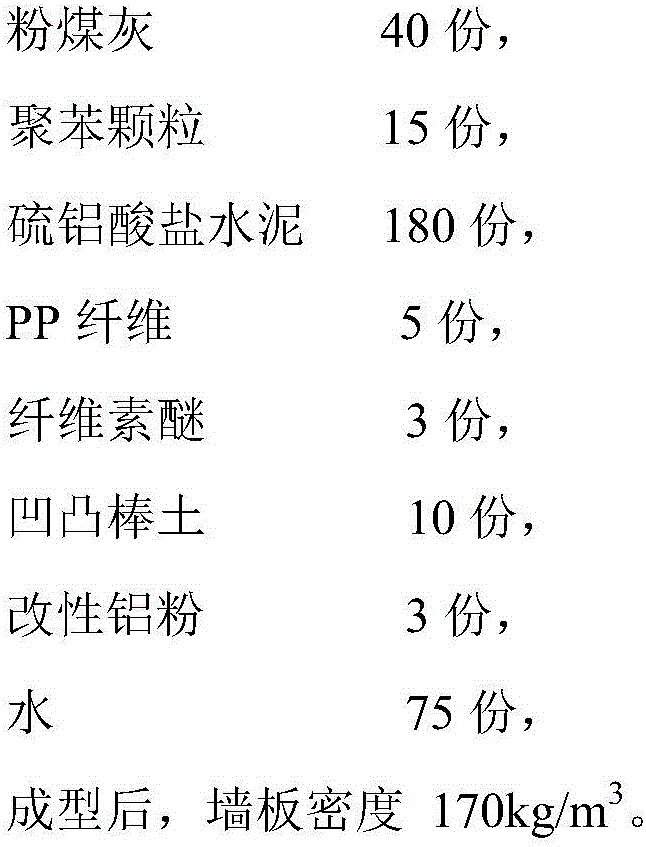

[0033] A fast-hardening lightweight wallboard, comprising the following raw materials in parts by weight:

[0034]

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a quick hardening type light wallboard. The quick hardening type light wallboard is characterized by comprising the following raw materials in parts by weight: 40-50 parts of coal ash, 15-20 parts of polyphenyl granule, 130-180 parts of sulphate aluminum cement, 2-5 parts of PP fiber, 1-3 parts of cellulose ether, 3-10 parts of attapulgite, 1-3 parts of modified aluminum powder and 55-75 parts of water; the bulk density of the coal ash is 555-700kg / m<3>; the bulk density of the polyphenyl granule is 12-21kg / m<3>; the grain size is 0.5-5mm; the sulphate aluminum cement is low-alkaline quick hardening sulphate aluminum cement and the mark number is 52.5; the length of the PP fiber is 5-10mm; the cellulose ether is hydroxypropyl methyl cellulose and the fineness is 100-200 meshes; and the fineness of attapulgite is 200-300 meshes. A preparing process for the modified aluminum powder comprises the following steps: heating and melting 1-5 parts by mass of polyethylene glycol powder and then quickly stirring; slowly adding 20-30 parts by mass of aluminum powder; drying the mixture; grinding and standing by. The excitant is prepared by mixing sodium silicate, sodium hydroxide, calcium bicarbonate and gypsum at a certain ratio and has the characteristics of light weight and high strength.

Description

technical field [0001] The invention belongs to the technical field of building materials, in particular to a fast-hardening lightweight wallboard. Background technique [0002] In order to meet the different needs of the construction market, wall panels such as thermal insulation wall panels, sound insulation wall panels, exterior wall panels, and decorative wall panels have appeared on the market. The country and localities and relevant departments have clearly stipulated that wallboard should be listed as a new type of wall material that is mainly supported for development. The location of the wallboard is different, and its raw material composition and production process requirements are also different. Multiple varieties and serialization are the needs of the development of the situation. [0003] At present, the wallboard materials on the market are mainly silicate, which has the disadvantages of long setting time, low early strength, and heavy weight, which cannot me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/06C04B38/08C04B38/02C04B111/40

CPCC04B28/06C04B2111/40C04B2201/05C04B2201/20C04B18/08C04B16/08C04B16/0633C04B24/383C04B14/102C04B22/04C04B38/02C04B38/08C04B14/045C04B22/062C04B22/10C04B22/143

Inventor 熊世平周雷昌

Owner 达州天创新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com