Plastic particle laser selecting and melting equipment

A technology for selecting melting and plastic particles, applied in the direction of additive processing, etc., can solve the problems of low work efficiency, long processing time, and high energy consumption of powder spreading process, and achieve the effect of improving efficiency, reducing energy consumption, and saving molding processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

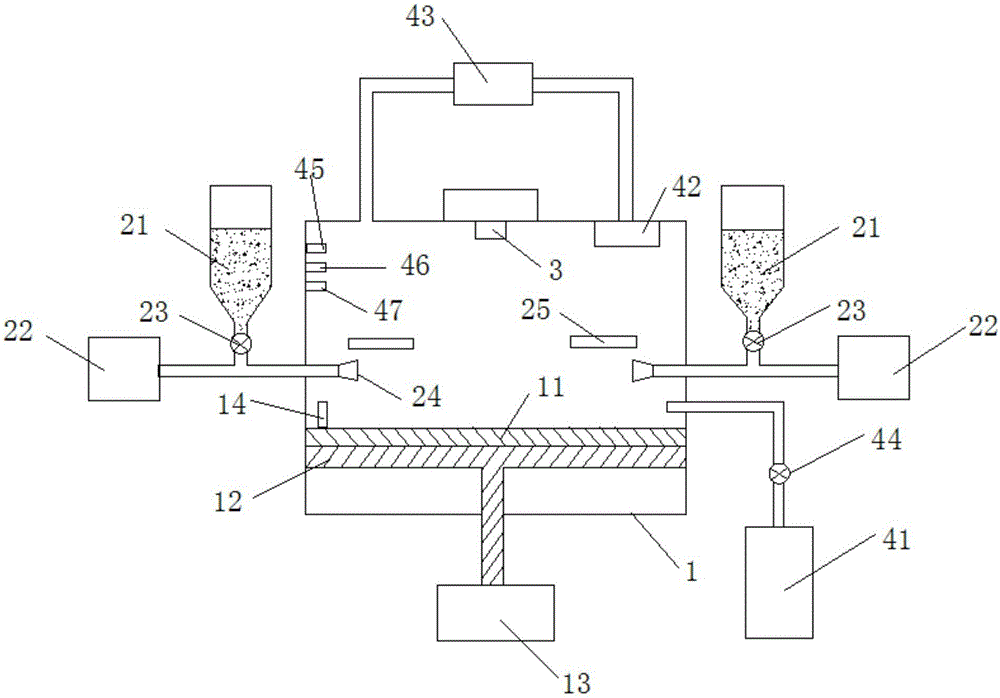

[0024] like figure 1 As shown, a plastic particle laser selection and melting equipment includes a sealed cabin 1, a powder feeding system, a laser light path system 3, and an atmosphere protection system, wherein: the sealed cabin 1 is provided with a horizontally placed forming platform 11, forming A lifting mechanism 12 is arranged in contact with the bottom of the platform 11, and the lifting mechanism 12 is driven by a servo motor 13. A powder scraper 14 is arranged on the upper surface of the forming platform 11; On both sides, the system includes a powder storage bin 21, a blower 22, a powder inlet valve 23, a pipeline and a nozzle 24. The pipeline communicates with the blower 22 and the nozzle 23, and the nozzle 23 is arranged inside the sealed cabin 1. The powder inlet valve 23 is arranged between the powder storage bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com