Injection molding processing device

A processing device and injection molding technology, which is applied in the field of glass fiber and carbon fiber composite material injection molding processing, can solve the problems that the front and rear coatings cannot be guaranteed to go vertical or cross, uniform and continuous coatings cannot be obtained, and the moving speed cannot be kept in sync. , to achieve the effect of shortening the molding processing time, shortening the molding time, and reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

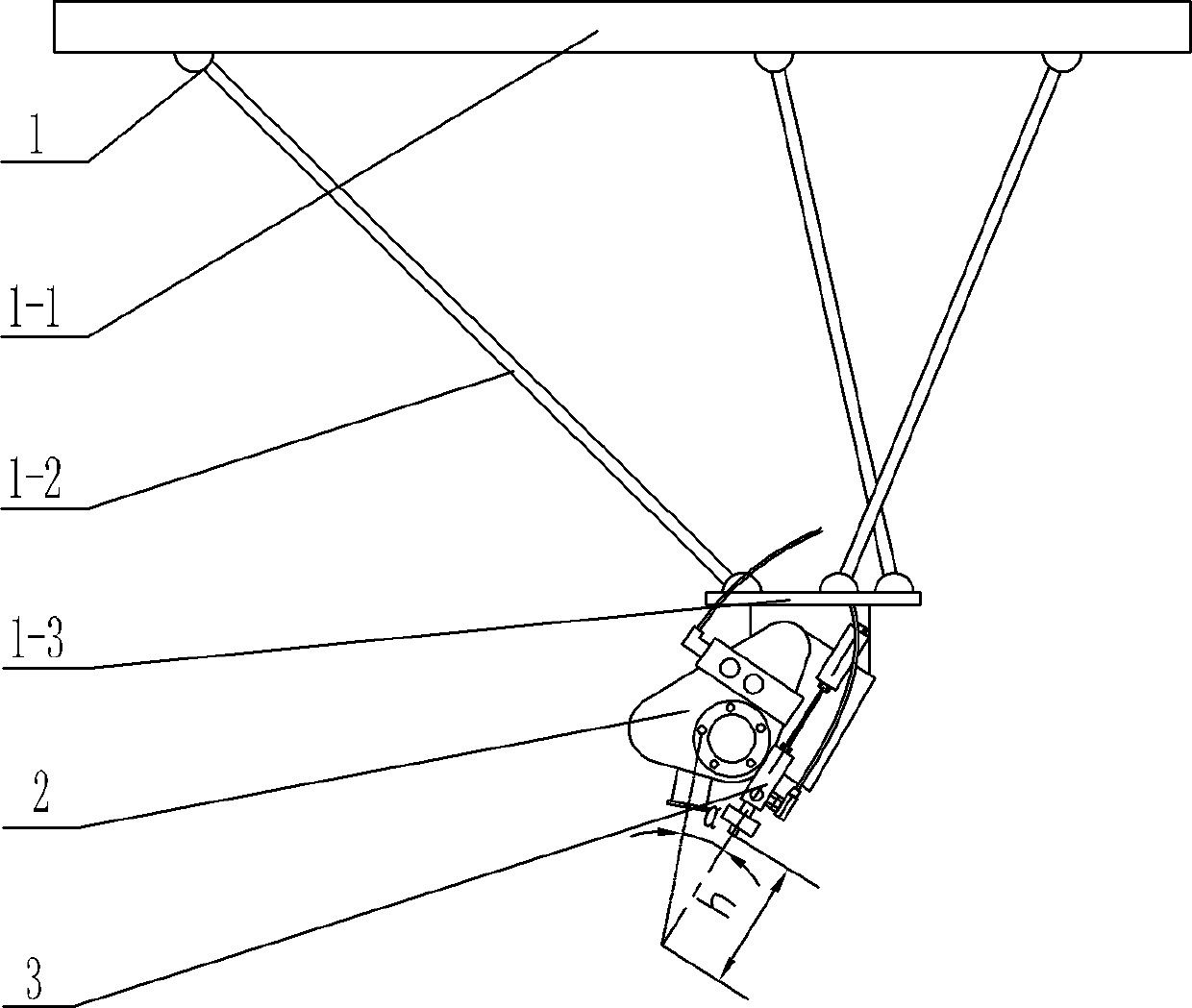

[0012] See figure 1 As shown, the injection molding processing device of the present invention includes an accelerator spray gun 2, an initiator spray gun 3 and a manipulator 1 programmed and controlled by a numerical control system, so that the manipulator 1 can act according to a certain prepared process route, see figure 1 As shown, the manipulator 1 of the present invention comprises an upper connecting seat 1-1, more than three connecting rods 1-2 and a lower connecting seat 1-3, and the upper and lower ends of each connecting rod 1-2 connected in parallel are connected with the upper connecting seat respectively. 1-1 and the lower connecting seat 1-3 are spherically hinged, and the lengths of the connecting rods 1-2 are not equal, the manipulator 1 is controlled by numerical control, and the flexibility of the action of the manipulator 1 is guaranteed. See figure 1 As shown, the accelerator spray gun 2 and the initiator spray gun 3 of the present invention are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com