Strain coordination layer for integral forming of ablative thermal protection structure as well as preparation method thereof and application

A technology of integral molding and coordinating layers, applied in the direction of chemical instruments and methods, applications, synthetic resin layered products, etc., can solve the problems of debonding between the heat-proof layer and the metal cabin, and the inability to meet the heat-proof structure of the adhesive film, and achieve The effect of short production cycle, improved impact resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

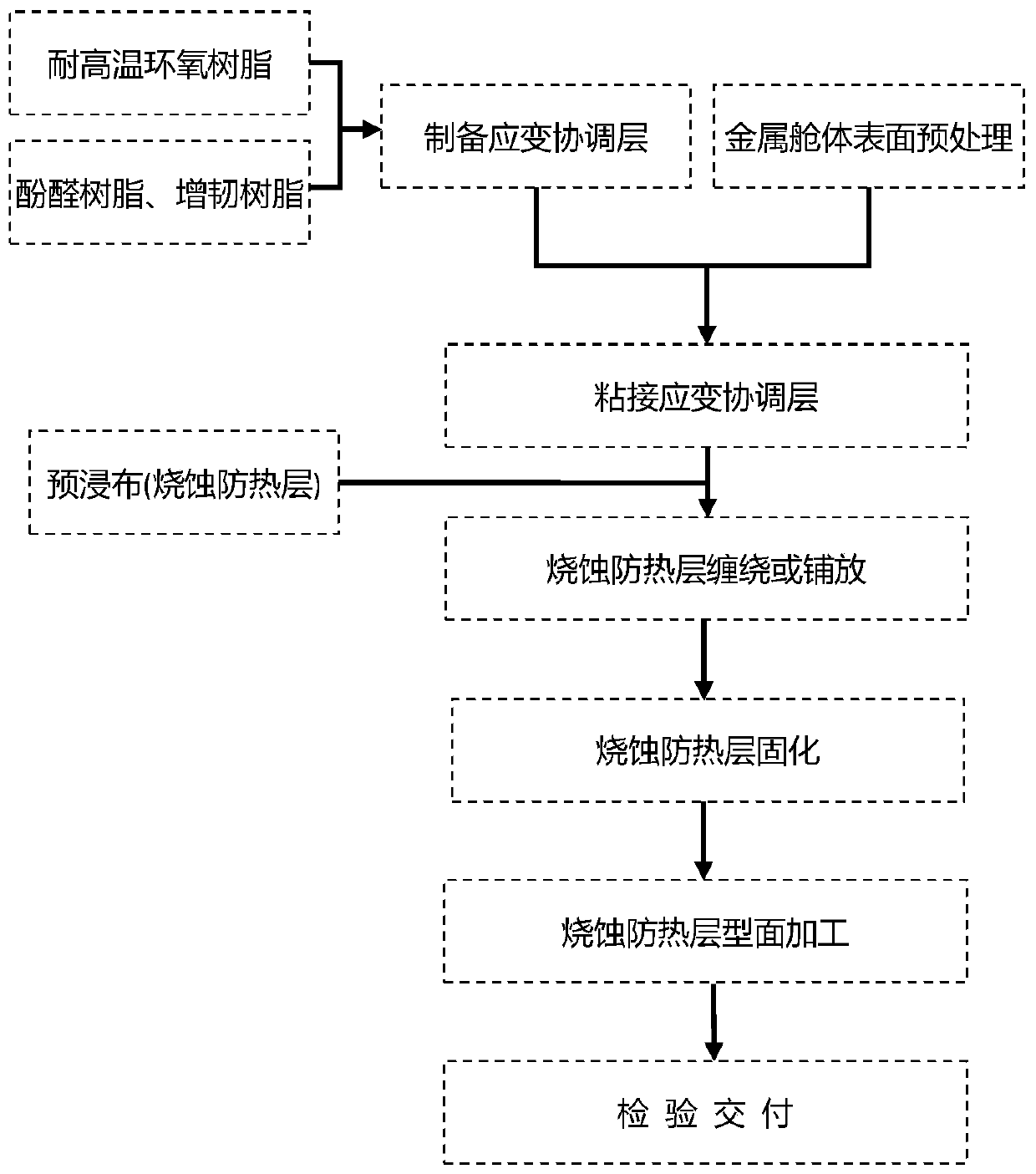

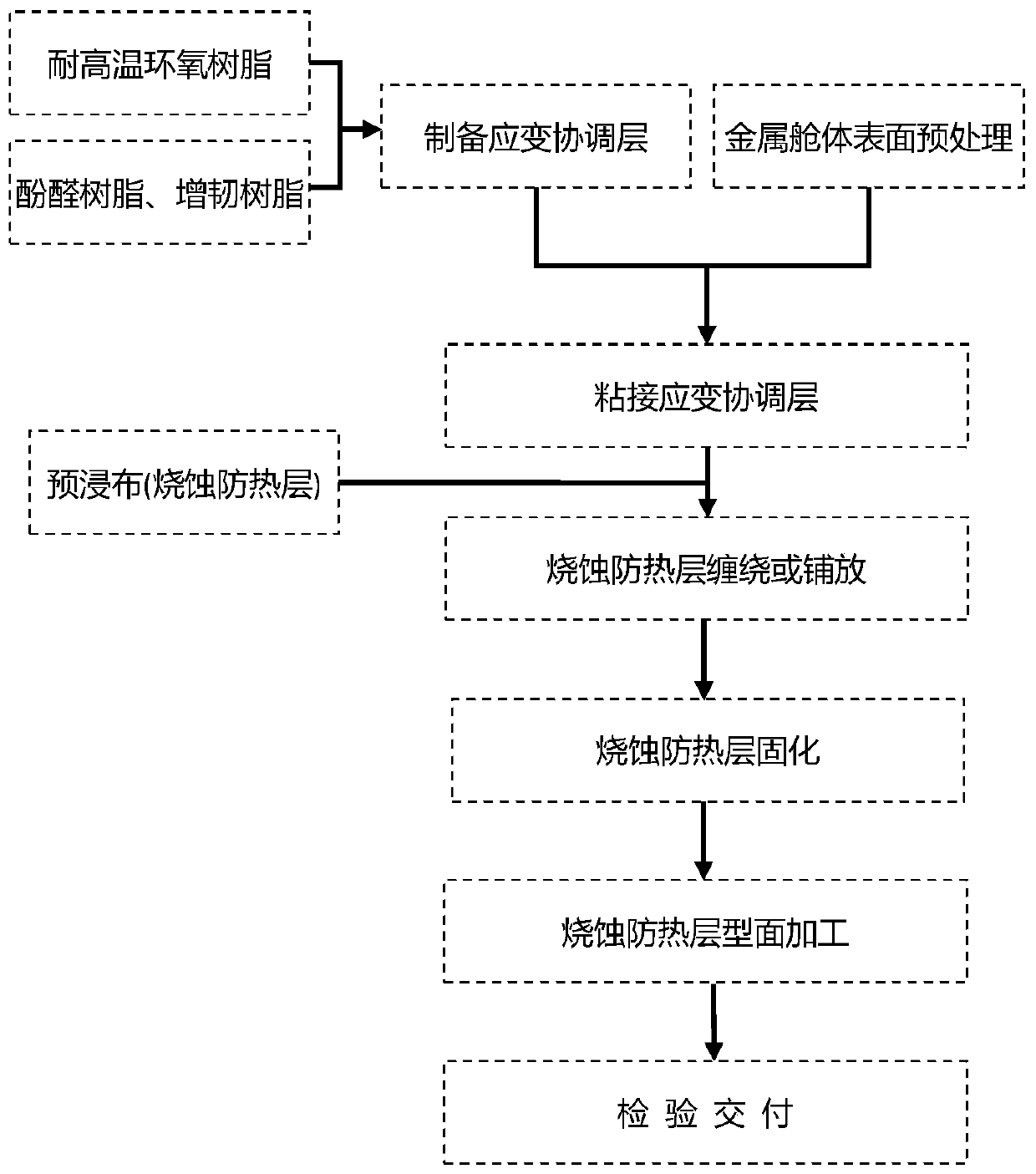

Method used

Image

Examples

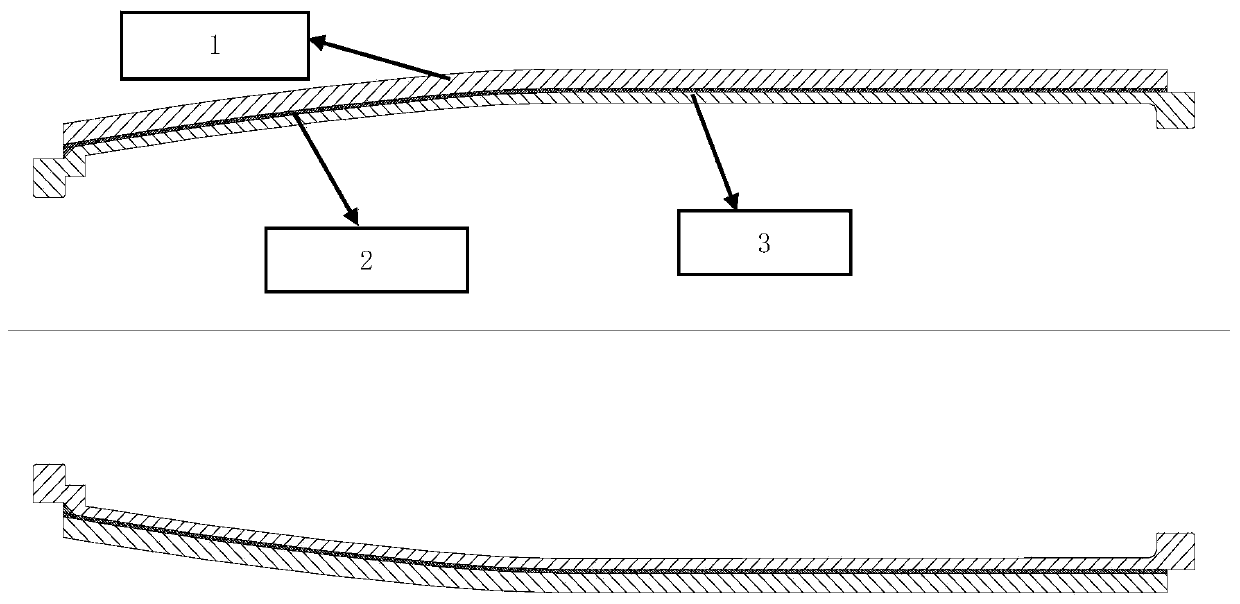

Embodiment 1

[0057] In this embodiment, the cabin structure is composed of a metal cabin, a strain coordination layer, and an ablation heat-resistant layer. The material of the metal cabin is 2A12 aluminum alloy, which is formed by spinning process. The strain coordination layer is a high temperature resistant phenolic modified epoxy resin system (80 parts of barium phenolic resin, 30 parts of bisphenol A epoxy resin and 8 parts of solid nitrile rubber), with a thickness of 0.8mm. The ablation-resistant fiber fabric in the ablation heat-resistant layer is high-silica fiber plain weave, and the ablation-resistant resin is barium phenolic resin. The pre-impregnated cloth tape is made by solution method, and the width of the cloth tape is 80mm. , the thickness is 8mm.

[0058] The strain coordination layer is prepared in the following way: the components used to prepare the high temperature resistant phenolic modified epoxy resin system are stirred at a constant temperature of 120°C for 3 ho...

Embodiment 2

[0068] Carry out in substantially the same manner as in Example 1, the difference being that the raw materials used to prepare the high-temperature-resistant phenolic modified epoxy resin system consist of 40 parts of barium phenolic resin, 50 parts of bisphenol A type epoxy resin and 15 parts of Parts of solid nitrile rubber composition.

Embodiment 3

[0070] Carried out in the same manner as in Example 1, the difference is that the raw materials used to prepare the high temperature resistant phenolic modified epoxy resin system consist of 120 parts of barium phenolic resin, 10 parts of bisphenol A type epoxy resin and 15 parts Parts of solid nitrile rubber composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com