Circular arc core pulling mechanism for injection mould

A core-pulling mechanism and injection mold technology, applied in the field of arc core-pulling mechanism, can solve problems such as inability to demold smoothly, and achieve the effect of ensuring smooth demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

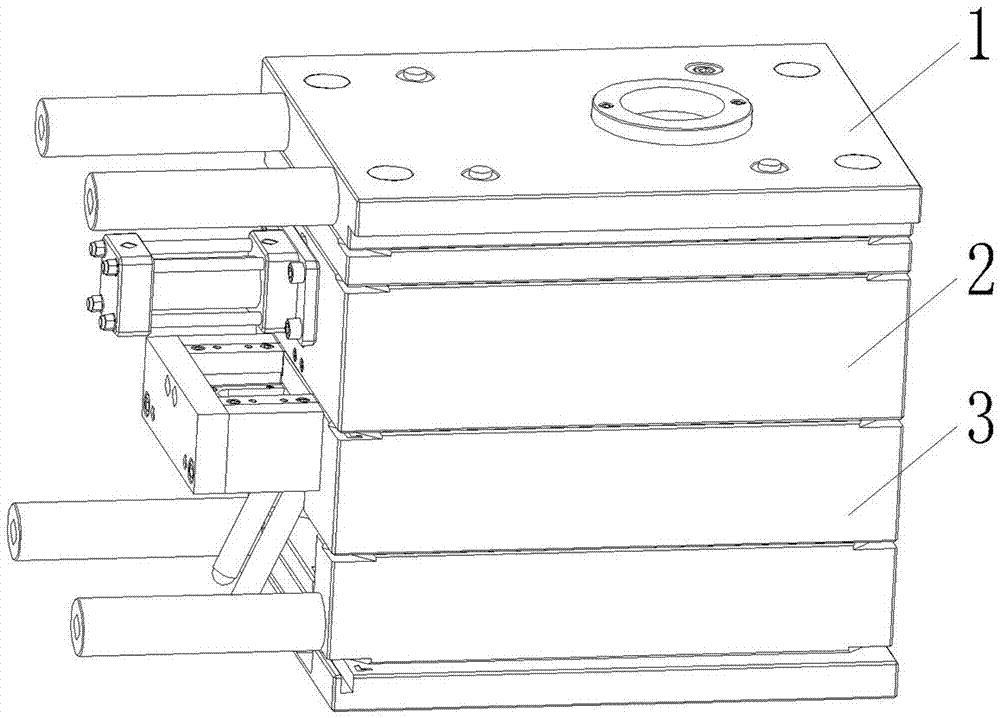

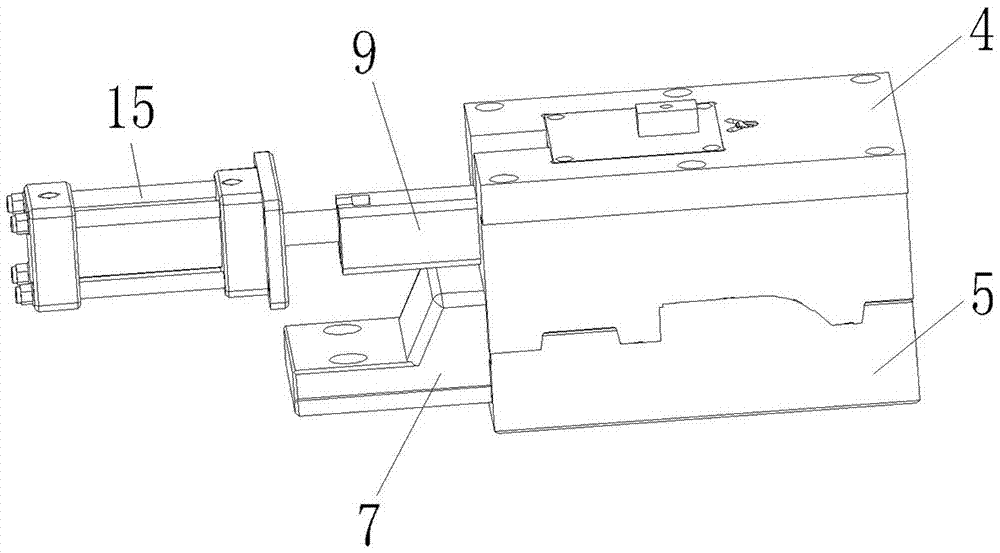

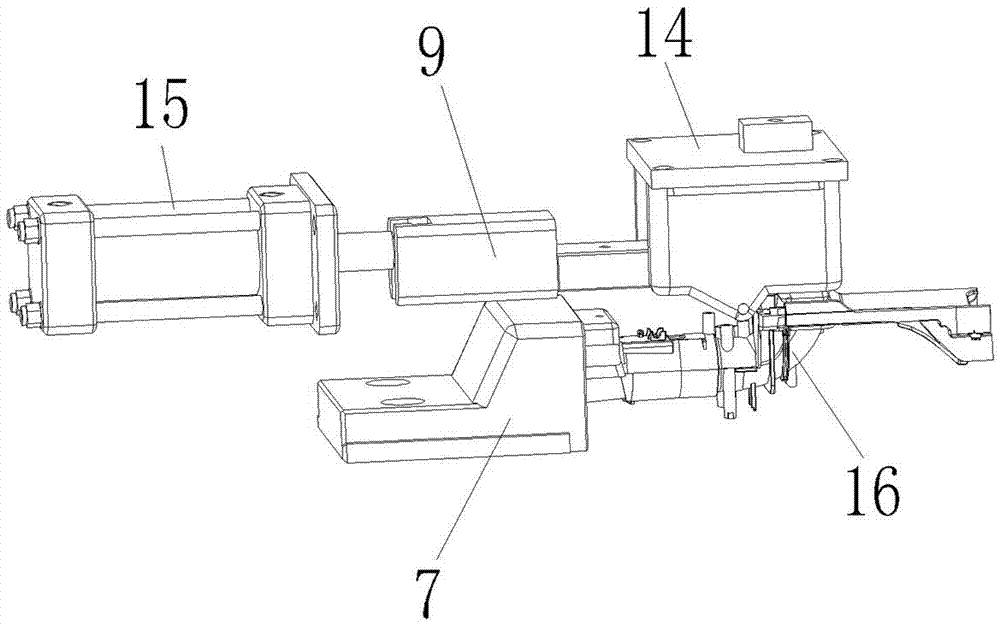

[0019] refer to Figure 1 to Figure 5 , an arc core-pulling mechanism of an injection mold, comprising a mold body 1, an upper mold base 2 and a lower mold base 3 are arranged in the mold body 1, a punch 4 is arranged in the upper mold base 2, and the The lower die base 3 is provided with a die 5, and when the upper die base 2 and the lower die base 3 are closed, the mold formed between the punch 4 and the die 5 Cavity, the said die 5 is provided with a straight first insert 6, said lower mold base 3 is provided with a measured first slider 7, said first slider 7 and said The first insert 6 is connected;

[0020] The punch 4 is provided with a curved second insert 8, the upper mold base 2 is provided with a measured second slider 9, and the front end of the second slider 9 is provided with a first connecting piece. Rod 10, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com