Glass door, manufacturing technique and refrigeration equipment

A technology of preparation process and glass door, which is applied in the field of preparation process, refrigeration equipment and glass door, which can solve the problems of long curing time of sealant, strong odor of sealant, slow production cycle, etc., so as to reduce labor cost and prevent frame condensation Dew, the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

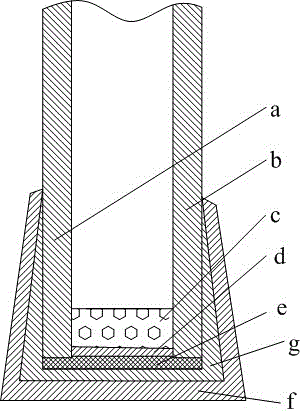

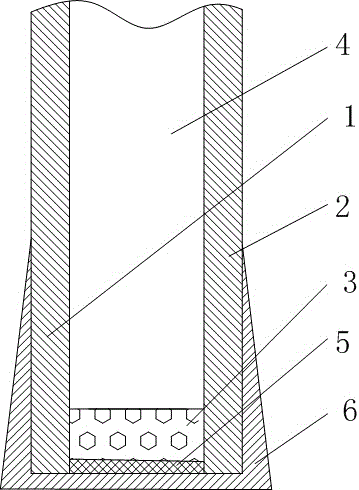

[0044] refer to figure 2 Shown is a structural cross-sectional view of a specific embodiment of the glass door according to the present invention. The glass door is a double-layer hollow glass door, including an outer glass 1, an inner glass 2, and a spacer bar 3. The outer glass 1 and the inner glass 2 are separated by a spacer 3 to form a hollow 4, the spacer 3 is made of PVC material, and the spacer 3 contains molecular sieve, which is used as a desiccant. The spacer 3 is located around the hollow 4, and the outer side of the spacer 3 is bonded between the outer glass 1 and the inner glass 2 by a sealant 5. The outer side of the sealant 5 is provided with a PU frame 6, and the PU frame 6 is simultaneously The surrounding edges of the inner glass 2 and the outer glass 1 are wrapped to form an all-encompassing structure. The cross section of the PU frame 6 is U-shaped. The PU frame 6 of this embodiment wraps around the hollow glass as a whole to form an integral frame. In t...

Embodiment 2

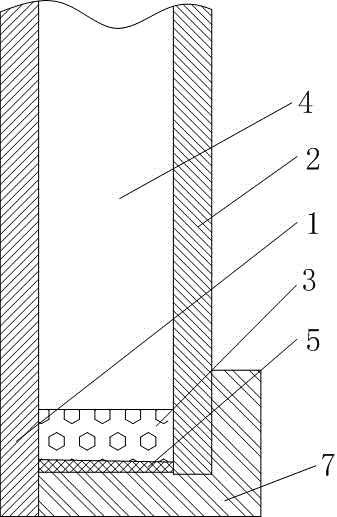

[0052] refer to image 3As shown, it is a structural cross-sectional view of another specific embodiment of the glass door according to the present invention. The glass door is a double-layer hollow glass door. The difference between this embodiment and Embodiment 1 is that the PU frame 7 only wraps around the edges of the inner glass 2. , the outer edge of the outer glass 1 is flush with the outer edge of the PU frame to form a half-wrapped structure, and the section of the PU frame 7 is L-shaped, such as image 3 shown. Others are the same as in Embodiment 1, and will not be repeated.

[0053] Of course, two pieces of inner glass 2 in the above-mentioned embodiment can also be used to form a three-layer hollow glass door, and the two pieces of inner glass are also separated by spacers to form a hollow space. The spacer bar 3 can also be made of aluminum or composite material. Composite materials usually use glass fiber and reinforced composite materials with a mass percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com