Method for physical preservation of soybeans

A fresh-keeping method, soybean technology, applied in the direction of preservation of edible seeds, preservation of seeds through radiation/electrical treatment, preservation of food ingredients as anti-microbial, etc., can solve problems such as food safety hazards, achieve odor and nutritional value guarantee, avoid The effects of food safety hazards and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

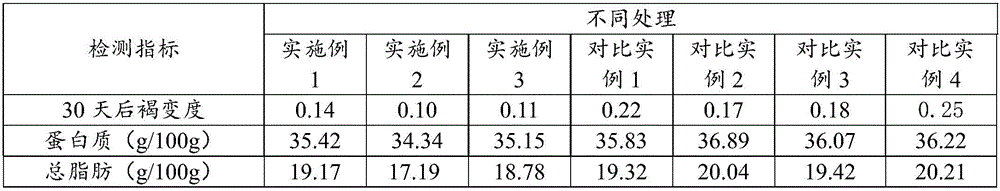

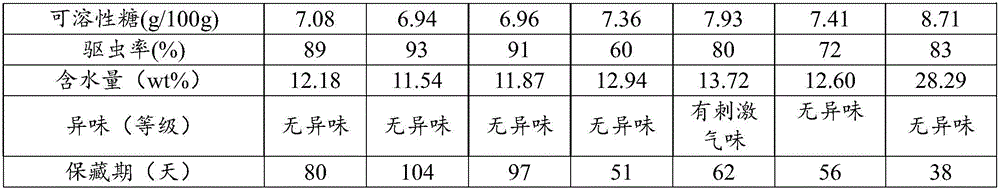

Embodiment 1

[0026] (1), selection: select soybeans that are fresh, mildew-free, insect-free, and mechanically damaged;

[0027] (2), soaking and cleaning: immerse the above-mentioned picked soybeans in ultrapure water, remove impurities and dust on the surface of the soybeans, and then sonicate for 0.5h;

[0028] (3), draining, air blowing and mixing treatment: quickly drain the treated soybeans in the dark at a low temperature of 1°C, and then dry them for 30min at 30°C with a mesh belt type airflow dryer;

[0029] (4) High-pressure osmosis treatment: Add mugwort essential oil into the heating chamber, promote the volatilization of mugwort essential oil at a constant temperature of 100°C, and use a high-pressure pump to pump the volatilized mugwort essential oil gas into the high-pressure air chamber equipped with red dates , and pressurize the high-pressure air chamber to ensure that the pressure in the high-pressure air chamber is at 10MPa. At this time, the gas of mugwort essential oi...

Embodiment 2

[0034] (1), selection: select soybeans that are fresh, mildew-free, insect-free, and mechanically damaged;

[0035] (2), soaking and cleaning: immerse the above-mentioned picked soybeans in ultra-pure water, remove impurities and dust on the surface of the soybeans, and then sonicate for 1.5 hours;

[0036] (3), draining, air blowing and mixing treatment: quickly drain the treated soybeans in the dark at a low temperature of 10°C, and then dry them for 45min at 50°C with a mesh belt air dryer;

[0037] (4) High-pressure osmosis treatment: Add mugwort essential oil into the heating chamber, promote the volatilization of mugwort essential oil at a constant temperature of 120°C, and use a high-pressure pump to pump the volatilized mugwort essential oil gas into the high-pressure air chamber containing soybeans , and pressurize the high-pressure air chamber to ensure that the pressure in the high-pressure air chamber is 15MPa, at this time, the gas of mugwort essential oil shows a d...

Embodiment 3

[0042] (1), selection: select soybeans that are fresh, mildew-free, insect-free, and mechanically damaged;

[0043] (2), soaking and cleaning: immerse the above-mentioned picked soybeans in ultrapure water, remove impurities and dust on the surface of the soybeans, and then sonicate for 1 hour;

[0044] (3), draining, air blowing and mixing treatment: quickly drain the treated soybeans in the dark at a low temperature of 5°C, and then dry them for 38min at 40°C with a mesh belt air dryer;

[0045] (4) High-pressure osmosis treatment: Add mugwort essential oil into the heating chamber, promote the volatilization of mugwort essential oil at a constant temperature of 110°C, and use a high-pressure pump to pump the volatilized mugwort essential oil gas into the high-pressure air chamber containing soybeans , and pressurize the high-pressure air chamber to ensure that the pressure in the high-pressure air chamber is at 13MPa. At this time, the gas of mugwort essential oil exhibits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com