Production method of superfine calcium carbonate special for high-gloss BOPP biaxially-oriented film

A biaxially oriented film, superfine calcium carbonate technology, applied in chemical instruments and methods, dyed polymer organic compound treatment, fibrous fillers, etc., can solve the problems of high cost, precipitation, unpleasant smell, etc. Good properties and aging resistance, simple production process and increased gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

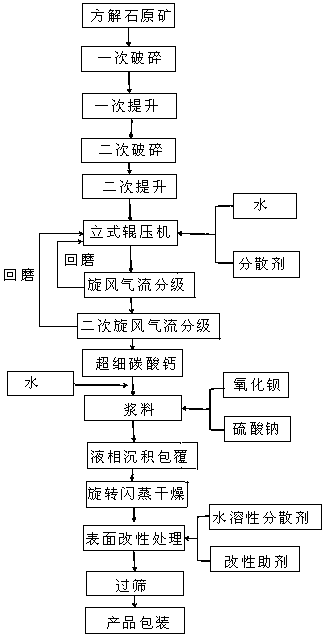

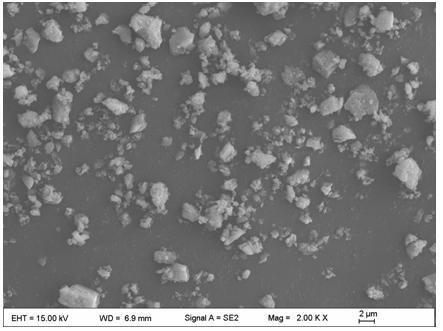

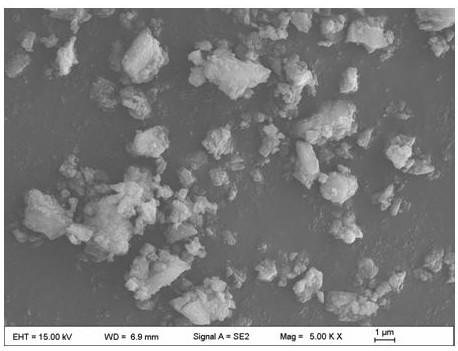

[0034] After crushing high-quality calcite ore, adding 7‰ sodium polyacrylate and 5‰ sodium lauryl sulfate dispersant, 12% water vertical roller grinding, and obtaining ultra-fine calcium carbonate through secondary cyclone classification; Fine calcium carbonate and water are prepared into a slurry with a solid content of 38%. At the same time, barium chloride solution and sodium sulfate solution are added dropwise to the slurry for liquid phase deposition coating. The stirring speed of liquid phase deposition coating is 650r / min, and the time is 45min; After the slurry is dried, it is surface-modified by a compound modifier, and 5‰ polyethylene glycol fatty acid ester, 5‰ polyaminoamide phosphate and 7‰ oleyl amino oleate water-soluble dispersant are added to the surface treatment; At the same time, 4‰ vinyl bis stearamide, 4‰ glyceryl tristearate and 7‰ monoglyceride stearate are added during surface modification treatment, sieved and packaged to obtain superfine calcium carb...

Embodiment 2

[0039] After crushing high-quality calcite raw ore, adding 7‰ sodium polyacrylate and 4‰ sodium lauryl sulfate dispersant, 10% water vertical roller grinding, and obtaining ultra-fine calcium carbonate through secondary cyclone classification; Calcium carbonate and water are prepared into a slurry with a solid content of 35%. At the same time, barium chloride solution and sodium sulfate solution are added dropwise to the slurry for liquid phase deposition coating. The stirring speed of liquid phase deposition coating is 550r / min, and the time is 45min. ; After the slurry is dried, it is surface-modified by a composite modifier, and 3‰ polyethylene glycol fatty acid ester, 3‰ polyaminoamide phosphate and 7‰ octadecylamine acetate water-soluble dispersant are added to the surface treatment ; Simultaneously add 7‰ vinyl bis stearamide and 8‰ monoglyceride stearate during surface modification treatment, sieve and pack to obtain superfine calcium carbonate.

[0040] The batch sampl...

Embodiment 3

[0043]After crushing high-quality calcite raw ore, adding 6‰ sodium polyacrylate and 6‰ sodium lauryl sulfate dispersant, 11% water vertical roller grinding, and obtaining ultra-fine calcium carbonate through secondary cyclone classification; Fine calcium carbonate and water are prepared into a slurry with a solid content of 35%. At the same time, barium chloride solution and sodium sulfate solution are added dropwise to the slurry for liquid phase deposition coating. The stirring speed of liquid phase deposition coating is 550r / min, and the time is 48min; After the slurry is dried, it is surface-modified by a composite modifier, and 4‰ polyethylene glycol fatty acid ester, 6‰ polyaminoamide phosphate and 8‰ aminopropylamine dioleate water-soluble dispersant are added to the surface treatment ; Simultaneously add 6‰ vinyl bis stearamide, 6‰ glyceryl tristearate and 3‰ monoglyceride stearate during surface modification treatment, sieve and pack to obtain superfine calcium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com