Electric dust removal device and catalyst coating formula

A catalyst coating and electrostatic precipitator technology, applied in physical/chemical process catalysts, chemical instruments and methods, deodorization, etc., can solve the problems of complex structure, low purification efficiency and small purification range of electric precipitator devices, and achieve purification effect And the effect of better sterilization effect, solving the problem of peculiar smell, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

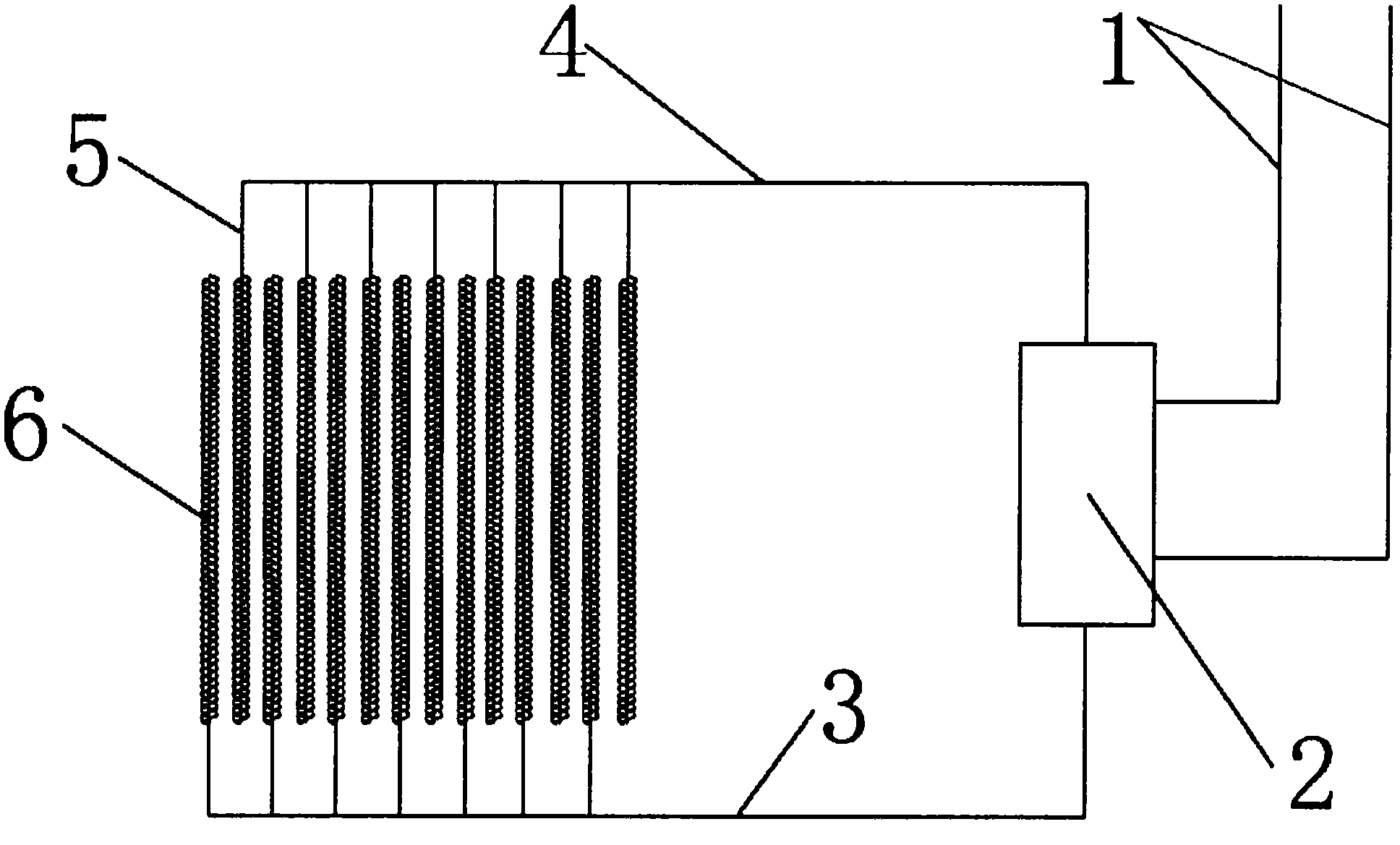

[0019] Such as figure 1 As shown, the present invention includes a power input line 1 , a high voltage generator 2 , a negative output line 3 , a positive output line 4 , an electrode plate 5 and a catalyst coating 6 . The power input line 1 is connected to the high voltage generator 2 . Both ends of the high voltage generator 2 are respectively connected to a positive output line 4 and a negative output line 3 . The positive output line 4 and the negative output line 3 are respectively connected to both ends of the electrode plate 5 . The electrode plate 5 is coated with a catalyst coating 6, and the thickness of the catalyst coating 6 is 0.1-0.5 mm.

[0020] The formula of catalyst coating is (components are in parts by mass):

[0021] 25 parts of copper oxide, 30 parts of manganese dioxide, 11.5 parts of tin oxide, 14.5 parts of titanium dioxide, 20 parts of aluminum tripolyphosphate.

[0022] The preparation method is:

[0023] 1. Mix 300-800 mesh copper oxide, mangan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com