Self-supporting cicada-preventing butterfly cable and production equipment for processing same

A self-supporting, butterfly cable technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of optical cable structure damage and excessive optical fiber attenuation, and achieve the effect of increasing fiber density and optimizing space area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in further detail below in conjunction with accompanying drawing:

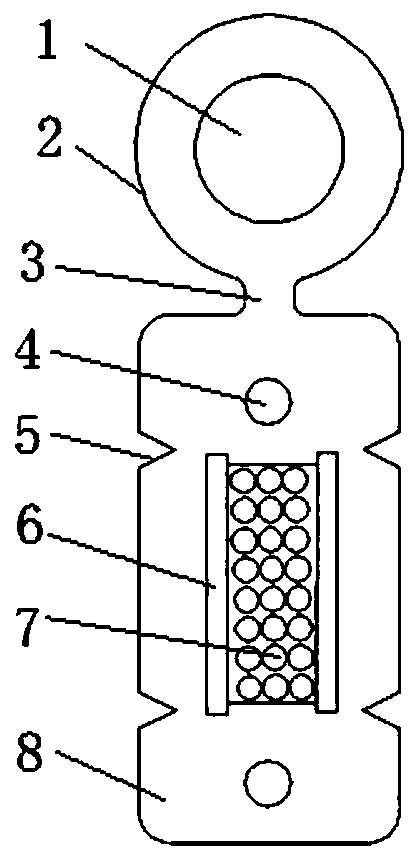

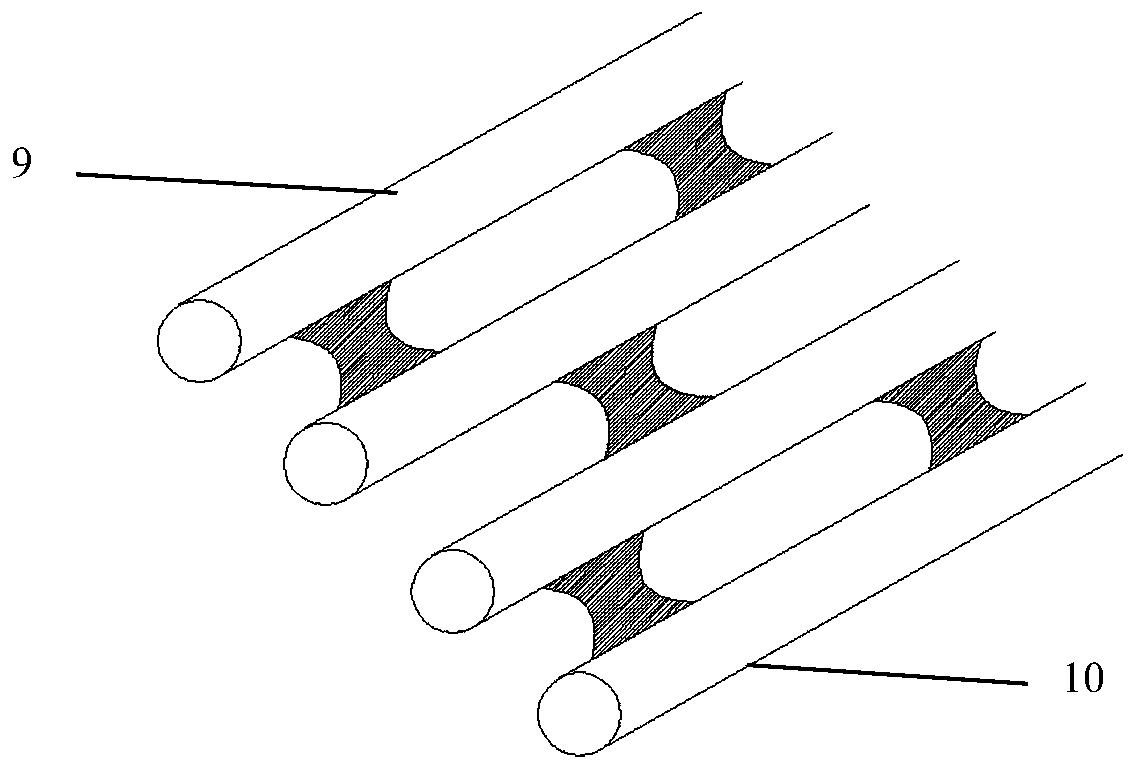

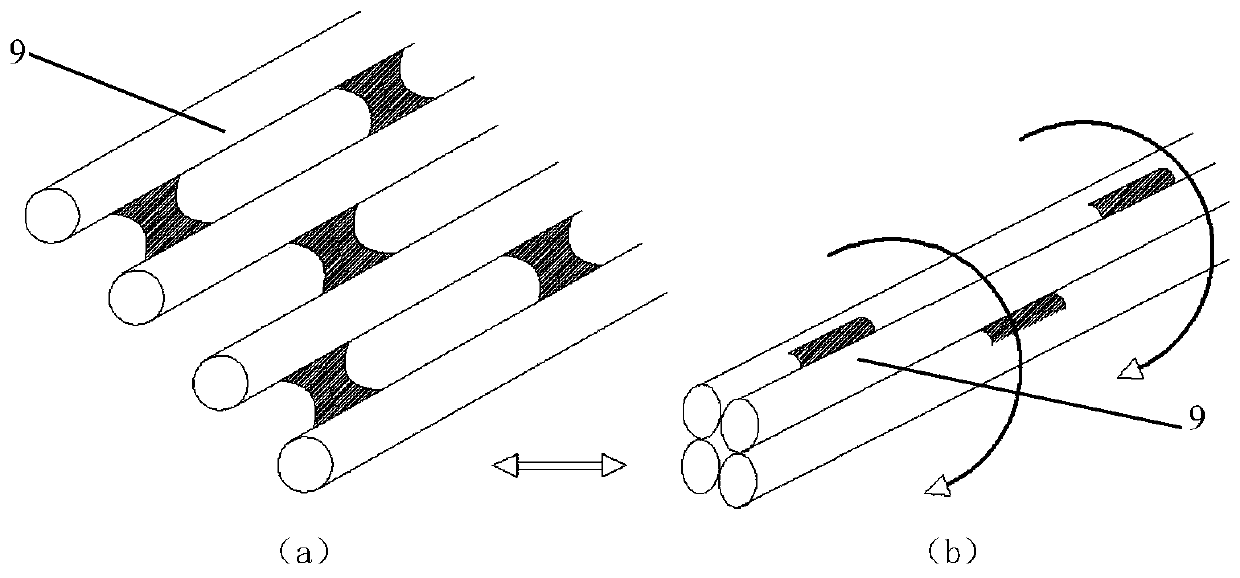

[0045] Such as figure 1 As shown, the present invention discloses a self-supporting anti-cicada butterfly cable, which is composed of a body part, a hanging neck part and a suspension wire part. Specifically, the body part includes a communication unit, a strengthening member 4 and an outer sheath 8 of an optical cable, and the communication unit It includes a winding optical fiber ribbon 7 and two symmetrically arranged protective sheets 6, and the winding optical fiber ribbon 7 is placed between the two protective sheets 6; the suspension part includes a suspension wire reinforcement 1 and a suspension wire outer sheath 2, and the hanging neck part includes a hanging neck 3.

[0046] The suspension wire reinforcement 1 of the optical cable is made of materials such as steel wire, steel strand or glass fiber rod, and functions as a self-supporting bearing for long-spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com