Ultrafine fiber moisture-absorbing quick-dry knitted fabric production method

A moisture-absorbing, quick-drying, knitted fabric technology, applied in knitting, fiber type, fiber treatment, etc., can solve the problems of rough hand feeling of quick-drying fabrics, and achieve good hand feeling and hygroscopicity, large specific surface area, and high fiber density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of production method of superfine fiber hygroscopicity quick-drying knitted fabric, comprises the following steps:

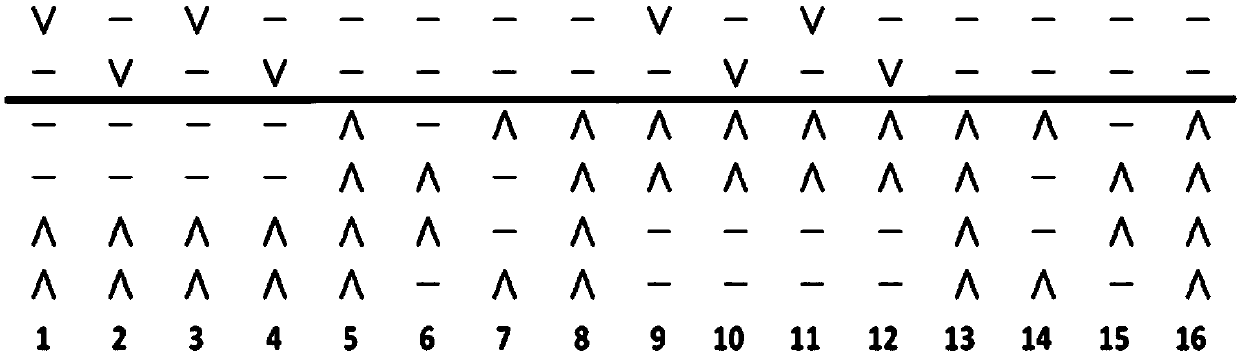

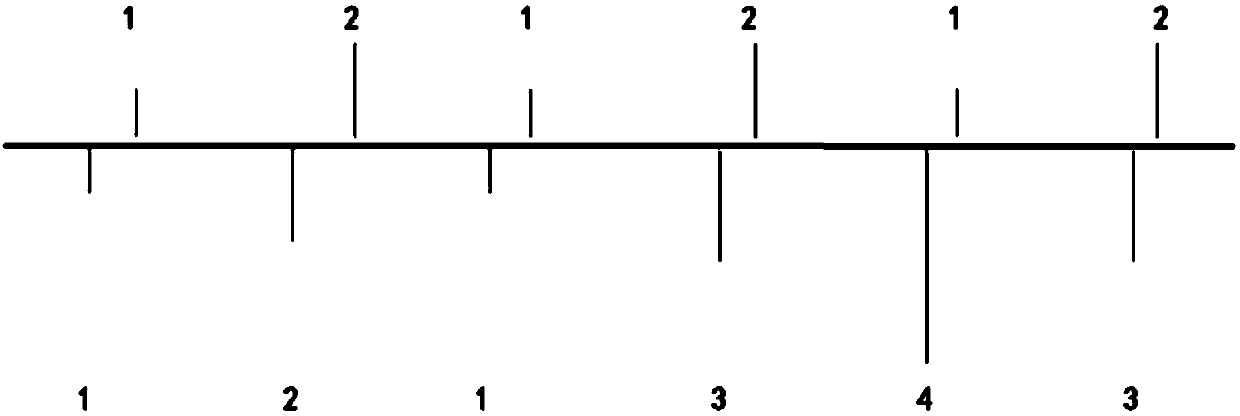

[0016] Provide a double-sided machine, arrange the triangles and knitting needles according to the requirements; in the present embodiment, adopt the double-sided machine of the Runshan RS model, the machine number 28G needle cylinder, and the cylinder diameter is 34 ". The triangle arrangement method is as follows figure 1 As shown, knitting needles such as figure 2 to arrange. in, figure 1 Among them, "∪∩" means tangle triangle; "∨∧" means circle triangle; "─" means floating line triangle. figure 2 middle figure 2 "∣"1 means the first knitting needle; 2 represents the second knitting needle. 3 means the second knitting needle; 4 represents the second knitting needle.

[0017] Yarns are provided, and the yarns include polyester-nylon composite stretch-textured yarns and cationic stretch-textured yarns; in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com