A kind of skin texture ceramic glaze

A technology of ceramic glaze and skin texture, which is applied in the field of ceramics, can solve the problems of thermal conductivity defects and thermal conductivity to be improved, and achieve the effects of low thermal conductivity, compact structure and improved porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

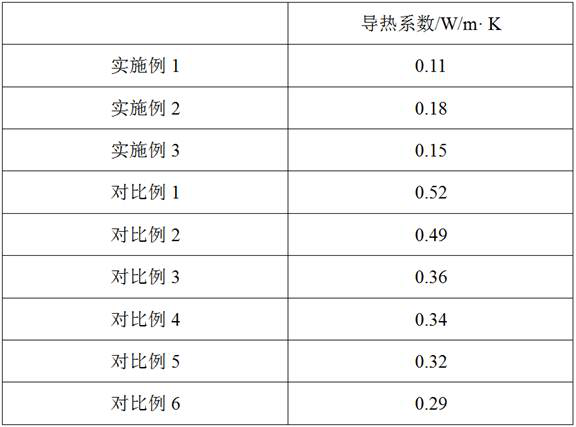

Embodiment 1

[0034] A skin texture ceramic glaze, the skin texture ceramic glaze is made of the following raw materials in parts by weight: 35 parts of dolomite, 27 parts of transparent frit, 11 parts of limestone, 8 parts of alumina whiskers, 6 parts of modified silicon Alumina fiber, 5.2 parts of calcined talc, 4 parts of vanadium pentoxide, and 3.8 parts of zirconium dioxide.

[0035] The preparation method of the skin-textured ceramic glaze is as follows: weighing each raw material component according to the proportion, stirring evenly with a mixer, firing at 1350° C., and crushing to 300 mesh. 325 mesh or less.

[0036] The transparent frit is made of the following raw materials in parts by weight: 31.2 parts of wollastonite, 25 parts of calcite, 17 parts of quartz, 12 parts of kaolin, 4.9 parts of silicon dioxide, 4 parts of borax, 2 parts of calcium oxide, and 1.8 parts of white carbon Black, 1.3 parts of zinc oxide, 0.8 parts of antimony trioxide.

[0037] The preparation method ...

Embodiment 2

[0047] A skin texture ceramic glaze, said skin texture ceramic glaze is made of the following raw materials in parts by weight: 30 parts of dolomite, 24 parts of transparent frit, 8 parts of limestone, 7 parts of alumina whiskers, 4 parts of modified silicon Alumina fiber, 4 parts calcined talc, 3 parts vanadium pentoxide, 3 parts zirconium dioxide.

[0048] The preparation method of the skin-textured ceramic glaze is as follows: weighing each raw material component according to the proportion, stirring evenly with a mixer, firing at 1350° C., and crushing to 300 mesh. The transparent frit is made of the following raw materials in parts by weight: 31.2 parts of wollastonite, 25 parts of calcite, 17 parts of quartz, 12 parts of kaolin, 4.9 parts of silicon dioxide, 4 parts of borax, 2 parts of calcium oxide, and 1.8 parts of white carbon Black, 1.3 parts of zinc oxide, 0.8 parts of antimony trioxide.

[0049] The preparation method of described aluminum oxide whisker is:

[0...

Embodiment 3

[0059] A kind of skin texture ceramic glaze, said skin texture ceramic glaze is made of the following raw materials in parts by weight: 40 parts of dolomite, 30 parts of transparent frit, 12 parts of limestone, 8 parts of alumina whiskers, 6 parts of modified silicon Alumina fiber, 7 parts of calcined talc, 6 parts of vanadium pentoxide, 4 parts of zirconium dioxide.

[0060] The preparation method of the skin-textured ceramic glaze is as follows: weighing each raw material component according to the proportion, stirring evenly with a mixer, firing at 1350° C., and crushing to 300 mesh.

[0061] The transparent frit is made of the following raw materials in parts by weight: 31.2 parts of wollastonite, 25 parts of calcite, 17 parts of quartz, 12 parts of kaolin, 4.9 parts of silicon dioxide, 4 parts of borax, 2 parts of calcium oxide, and 1.8 parts of white carbon Black, 1.3 parts of zinc oxide, 0.8 parts of antimony trioxide.

[0062] The preparation method of described alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com