A method for making integral vacuum glass and an integral vacuum glass

A technology of vacuum glass and its manufacturing method, which is applied to glass manufacturing equipment, glass forming, manufacturing tools, etc., which can solve the problems of low production efficiency, low safety, high scrap rate, etc., to eliminate easy displacement and enhance sealing strength , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

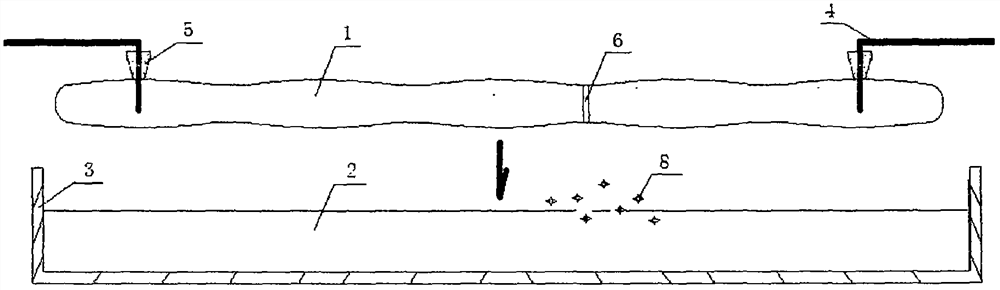

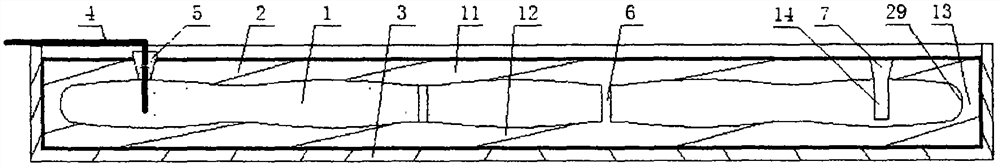

[0042] Embodiment one: if figure 1 , figure 2 , image 3 As shown, (1) first use the cohesive soil in the mandrel mold, which can still maintain its shape in the atmosphere of 300 ° C - 780 ° C, and become loose, melted, and slurry after contact with water or use soil as the base The mixture of cementing materials completes the manufacture of the temperature-resistant mandrel; (2) In the atmosphere of 300°C-780°C, heat-melt the low-melting point glass frit 8 placed in the mold 3 into a fluid or plastic state glass frit 2 Place the temperature-resistant mandrel 1 in the glass frit 2 through the positioning rod 4 covered with the separation ring 5, so that there is a gap of 3mm-6mm between the side wall 29 of the temperature-resistant mandrel and the mold 3, and make the glass frit 2 wrap the temperature-resistant mandrel 1 and fill the pin holes 6, demould after cooling to obtain a plate body with a temperature-resistant mandrel 1 inside; (3) remove the separation ring 5, th...

Embodiment 2

[0043] Embodiment two: if Figure 4 As shown, (1) Spread a layer of low-melting point glass frit 8 with a thickness of 3 mm to 10 mm on the inner surface of the mold 3, and place the temperature-resistant mandrel 1 on the mold 3 through the positioning rod 4 covered with the separation ring 5 The surface of the low-melting-point glass frit 8 of the plate body sprinkled in the middle, and a gap of 3 mm to 6 mm is left between the side wall 29 of the temperature-resistant mandrel and the mold 3, and then the accurately measured low-melting-point glass frit 8 of the plate body is placed on the heat-resistant mandrel. The gap between the warm mandrel 1 and the mold 3, the pin hole 6 and the upper surface of the temperature-resistant mandrel 1; (2) heat-melt the low melting point glass frit 8 of the plate body in the atmosphere of 300°C-780°C to form a fluid glass frit, so that the glass frit is filled The gap between the temperature-resistant mandrel 1 and the mold 3 and the pin h...

Embodiment 3

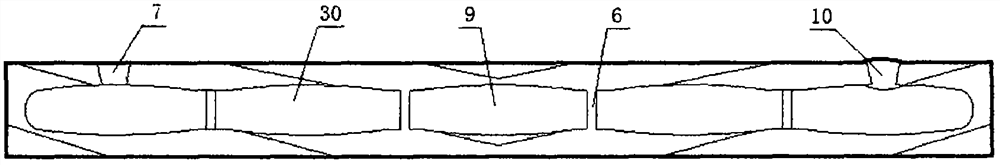

[0044] Embodiment three: as Figure 5 As shown, (1) on the separation layer 15 made of 0.05mm - 0.3mm metal sheet, open a separation layer pin with a diameter of 2mm - 6mm at the position corresponding to the pin hole 6 on the temperature-resistant mandrel 1 Holes 16; (2) sandwich a separation layer 15 between two or more heat-resistant mandrels 1, so that the pin holes of the temperature-resistant mandrel 1 and the separation layer 15 are connected to form a through-pin hole 18, and the periphery of the separation layer 17 Leave or protrude from the side of the temperature-resistant mandrel 1 by 2 mm——10 mm; (3) Repeat this, that is, complete the layout of the multi-layer temperature-resistant mandrel 1 and the intervening layer 15 to form a heat-resistant mandrel module; (4) at 300°C——780 ℃ atmosphere, heat-melt the low-melting-point glass frit 8 put into the mold 3 into a fluid frit 2, and place the temperature-resistant core module in the frit 2 through the positioning rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com