Gear part shaving fixture

A technology of parts and fixtures, which is applied in the field of shaving fixtures for gear parts, can solve the problems of gear tooth profile difference and large positioning gap, etc., and achieve the effects of low cost, improved precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

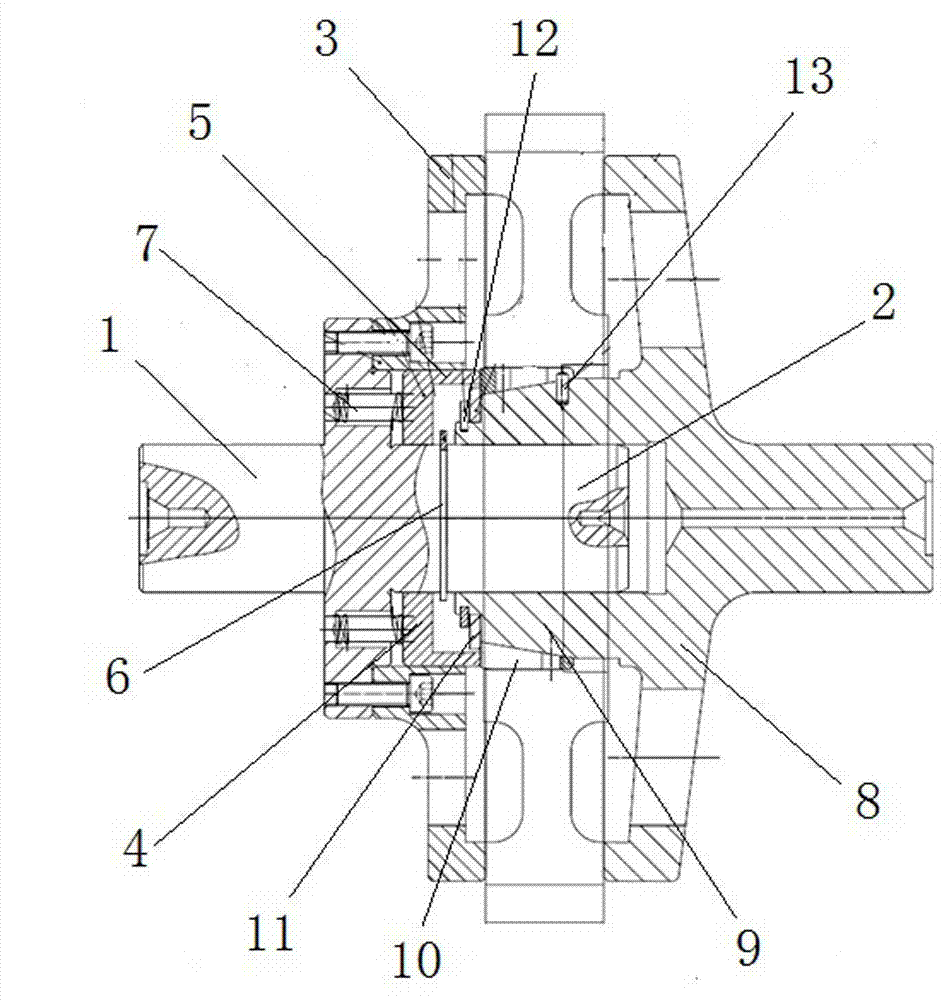

[0009] Gear parts shaving fixture, including the left spindle assembly and the right spindle assembly arranged between the left and right tops of the gear shaving machine; the left spindle assembly includes a stepped left base 1, the center of which is fixed There is a mandrel body 2, a hollow left positioning seat 3 is connected to the right end of the left base 1, a pressure pad 4 is arranged in the left positioning seat 3, a pressure ring 5 is provided on the right side of the edge of the pressure pad 4, and a pressure ring 5 is provided on the mandrel body 2. The left snap spring 6 on the right side of the pad 4, the tension spring 7 in contact with the pressure pad 4 is arranged in the left base 1; the right spindle assembly includes a stepped right positioning seat 8, and the left end surface of the right positioning seat 8 is provided with The tapered sleeve 9 is set on the mandrel body 2. The slope of the tapered sleeve 9 is covered with a spring sleeve 10 corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com