Patents

Literature

44results about How to "Large heat radiation area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

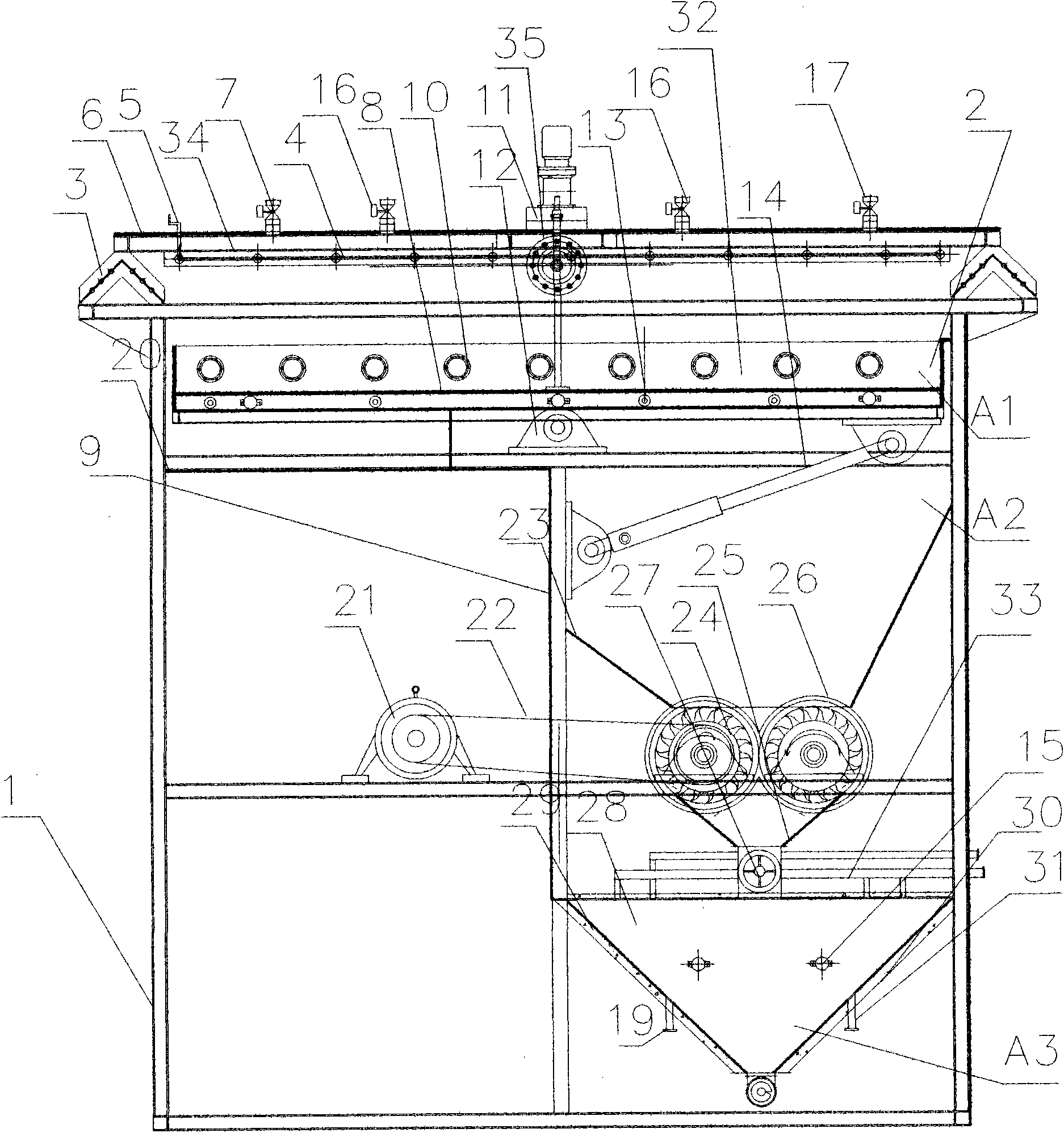

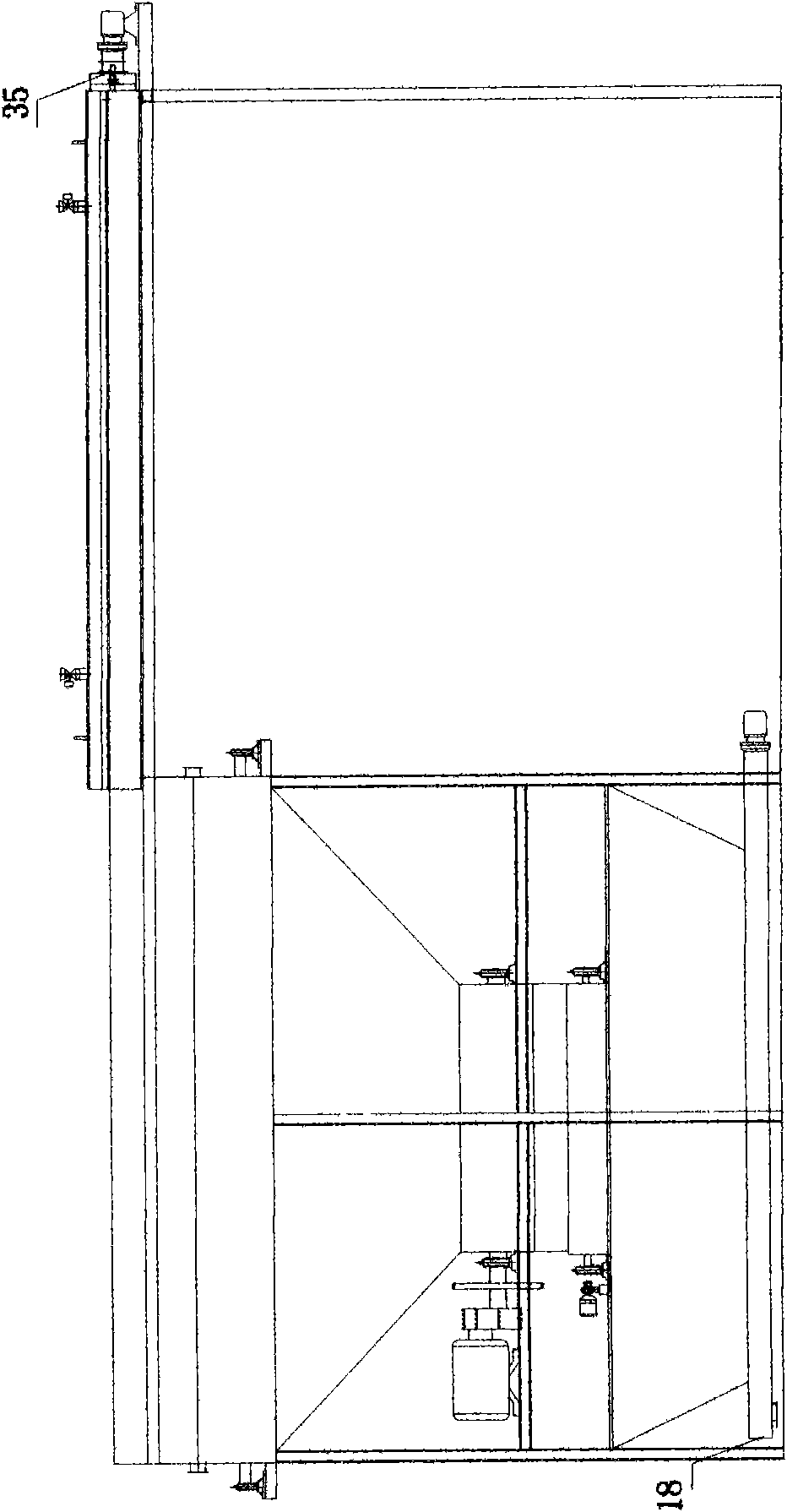

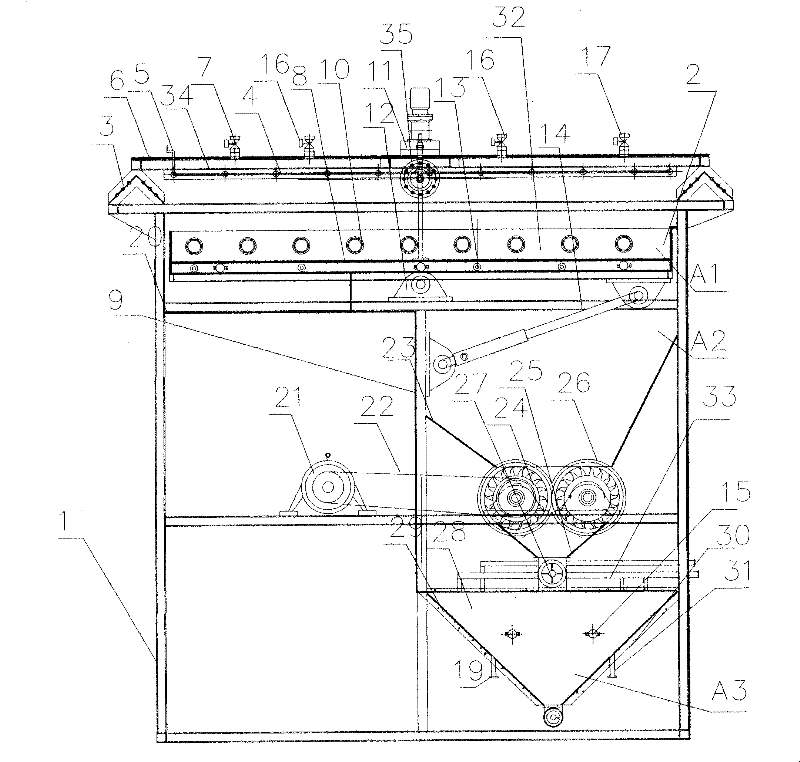

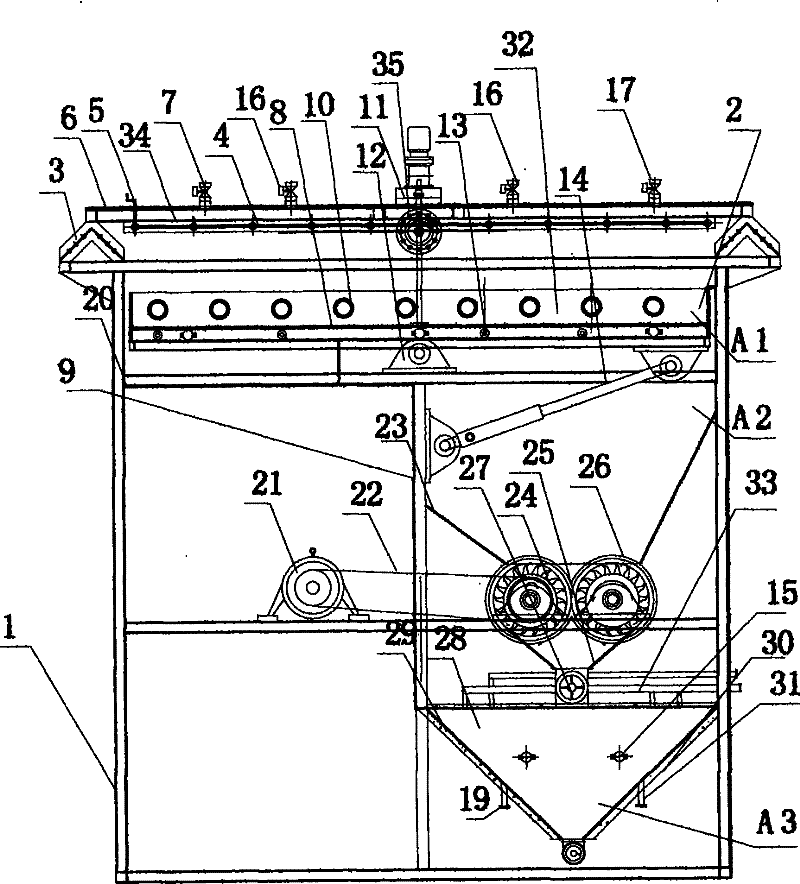

Microwave heating type cracking furnace

InactiveCN101633847AEvenly heatedLarge heat radiation areaBiofuelsSpecial form destructive distillationMicrowavePositive pressure

The invention relates to a microwave heating type cracking furnace for saving fuel resources in a production process. The invention adopts the technical scheme that the microwave heating type cracking furnace comprises a closed heating furnace body and a matched heating, pressure-maintaining and pyrolysis atmosphere maintaining mechanism and adopts a structure integrating pyrolysis, carbonization and activation. The structure comprises the furnace body and a sliding sealed cover plate which is arranged at the furnace top; the pyrolysis furnace body comprises a pyrolysis furnace chamber which uses a microwave heat source and an activation chamber arranged below the pyrolysis furnace chamber; wherein the pyrolysis furnace chamber is in a positive-pressure, nitrogen-atmosphere and movably sealing-type structure; the sliding sealed cover plate at the top of the pyrolysis furnace chamber is provided with a reverse V-shaped groove rail made of sealing material and a sealing-type friction pair; the reverse V-shaped groove rail is made of embedded sealing material; and the sealing-type friction pair slides with the matched reverse V-shaped groove rail arranged at the upper end of the pyrolysis furnace body. The structure comprises a shell-type stand, and a space in the furnace body is separated into the pyrolysis furnace chamber and the activation chamber by the match of a sealing separator II and the elastic sealing material arranged on a shell in match with a movable sealing matching part. The invention integrally realizes four-in-one operation and has simple structure and strong reliability.

Owner:深圳市兖能环保科技有限公司

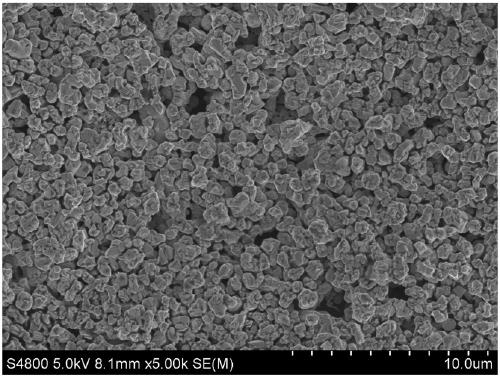

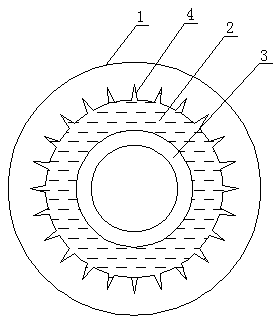

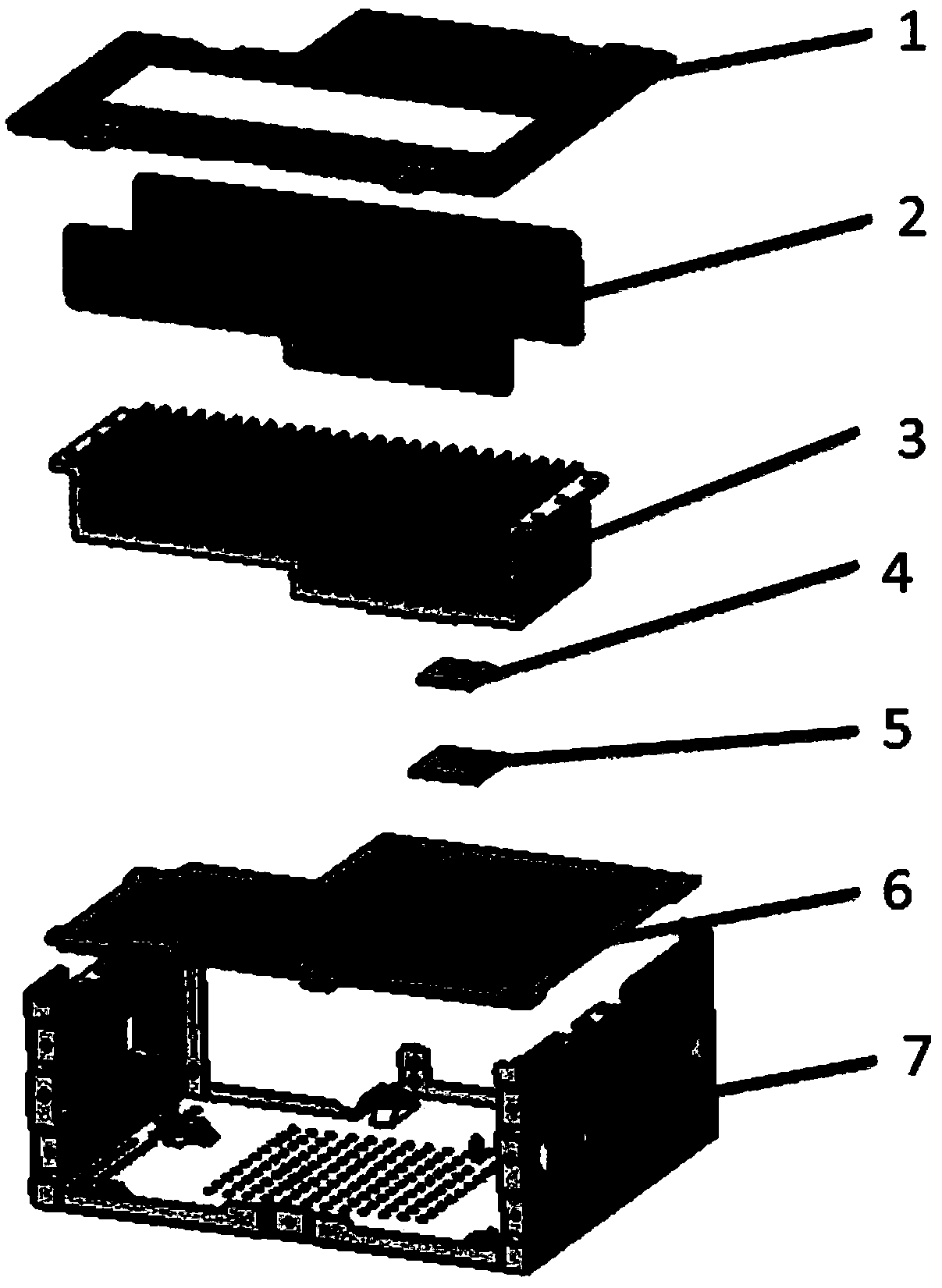

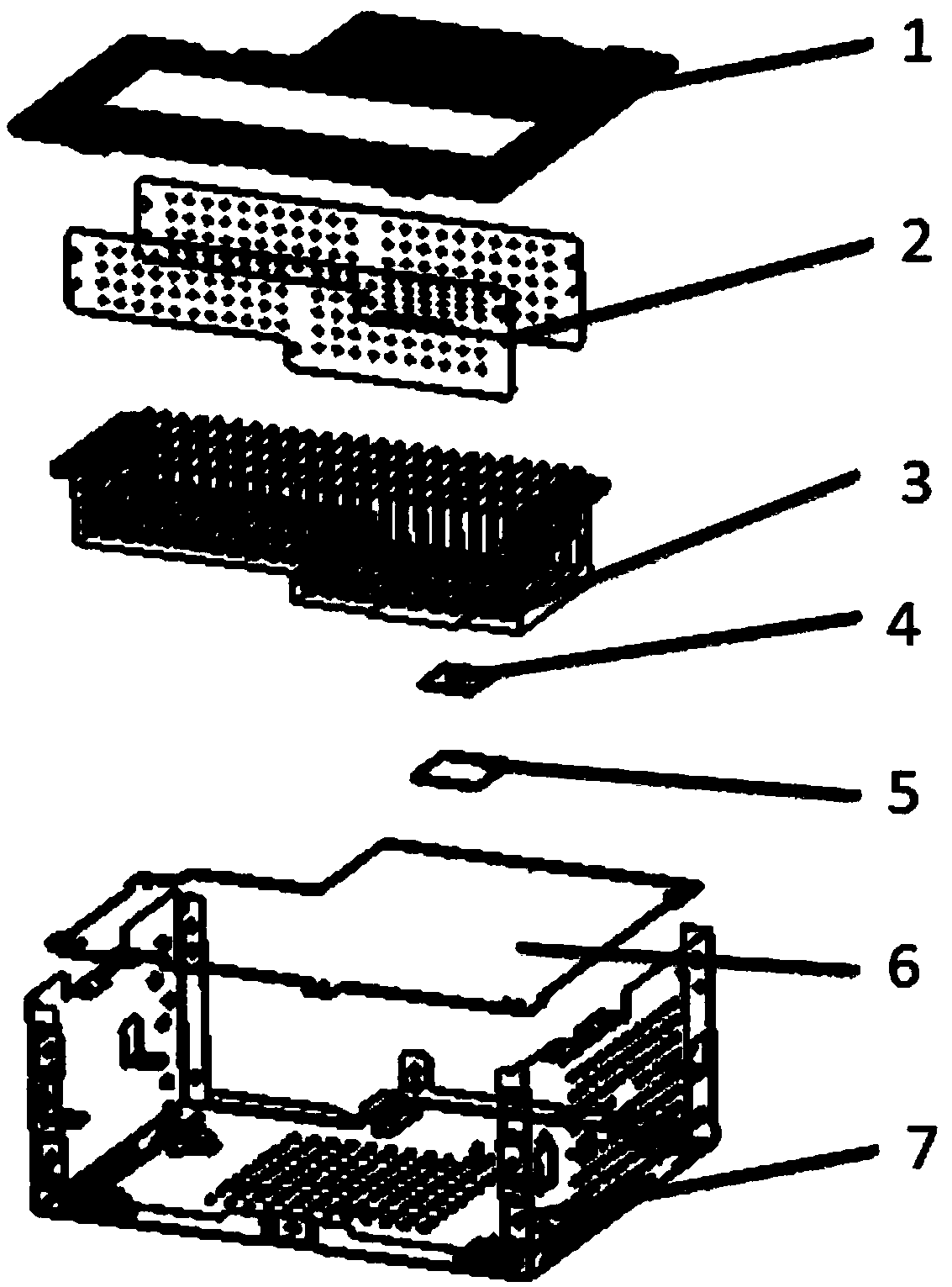

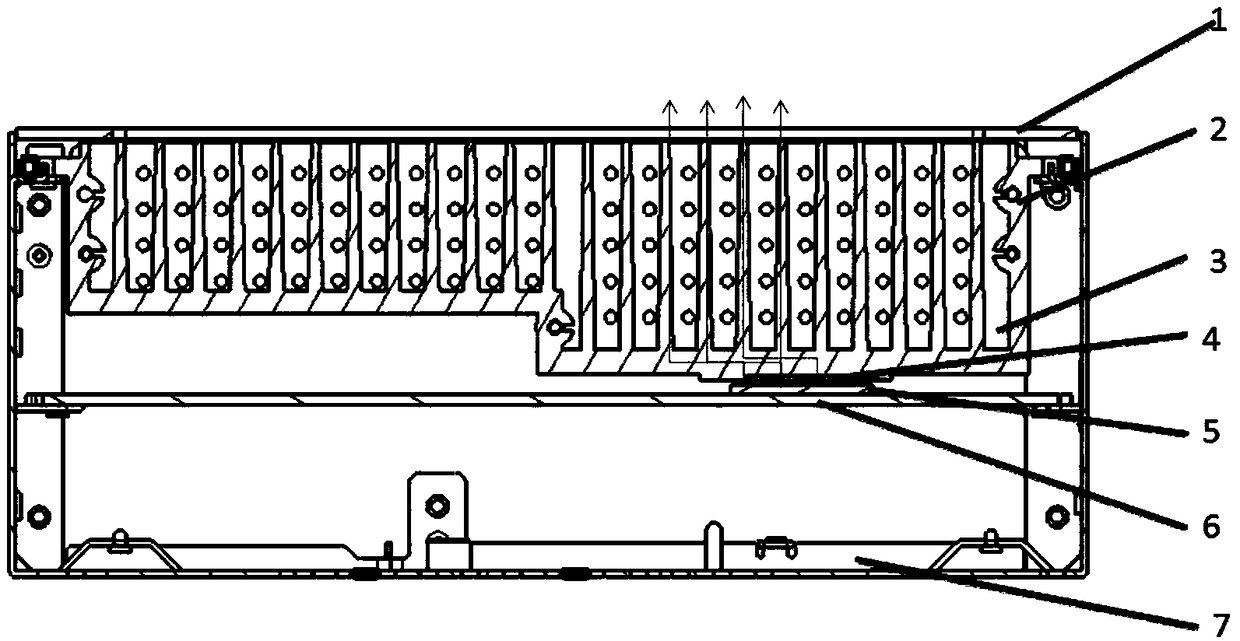

Heating element with porous ceramic coating

ActiveCN109321803ALarge heat radiation areaIncrease heat radiation rateChemical vapor deposition coatingNiobiumCeramic coating

The invention provides a heating element with a porous ceramic coating. The heating element with the porous ceramic coating comprises a metal base body and the porous ceramic coating composited on thesurface of the metal base body; the porous ceramic coating comprises a metal phase and a ceramic phase; the mass percentage of the metal phase in the porous ceramic coating is 0-50%; the metal phaseis composed of one or more of tungsten, molybdenum, tantalum, zirconium, niobium and hafnium; and the ceramic phase is one or more of carbide of rare metal, nitride of rare metal, oxide of rare metal,carbide of boron, nitride of boron, oxide of boron, aluminum oxide and magnesium oxide. The coating body in the heating element is ceramic powder, metal powder serves as an adhesion agent, and the porous ceramic coating is prepared. The coating with the ceramic material as the body can increase the heat radiation rate of the element, meanwhile, due to the fact that the ceramic coating is of a loose porous structure, the heat stress generated due to the heat expanding coefficient difference of the base body and the coating can be effectively reduced, and the coating is not prone to cracking orfalling.

Owner:SUZHOU IMOTECH MATERIALS TECH CO LTD

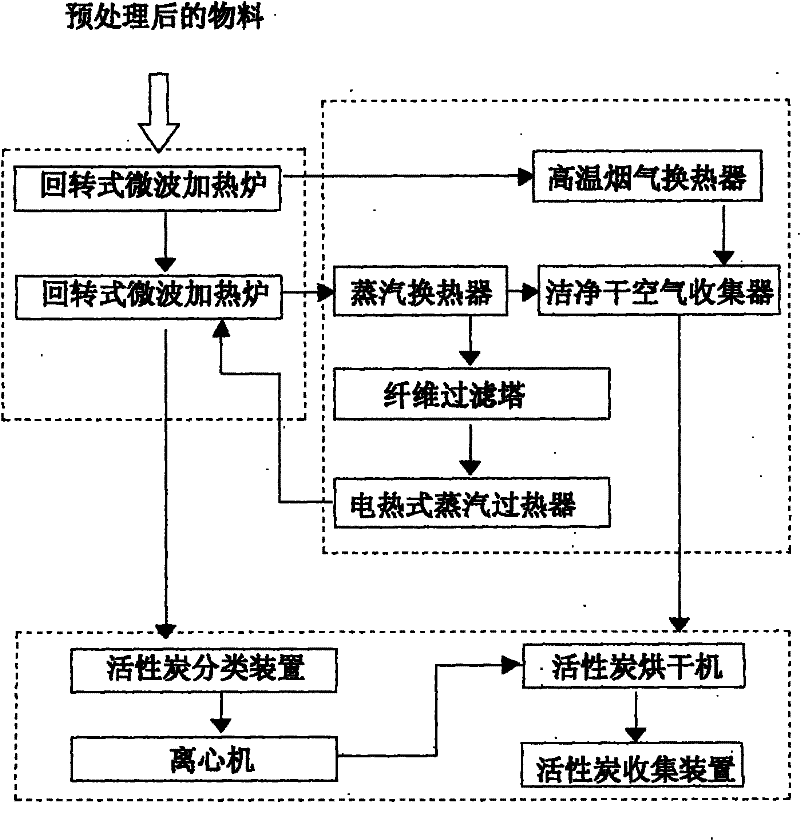

Operating method of rotary waste incineration fly ash microwave sintering ceramsite

ActiveCN108972865AImprove sintering efficiencyIncrease profitRotary drum furnacesCharge composition/stateLitterSulfur

The invention discloses an operating method of a rotary waste incineration fly ash microwave sintering ceramsite. According to the method, waste incineration fly ash and pyrite cinder are mixed and granulated, the granulated waste incineration fly ash and pyrite cinder and microwave coupling agent powder enter a rotary furnace body together to be subjected to microwave sintering, by obliquely arranging a rotary reaction furnace, the ceramsite is subjected to microwave heating while rolling and mixing are carried out, the ceramsite clinker is separated from the microwave coupling agent when thesintering is carried out, and the separated microwave coupling agent is used as a raw material to be returned and reused; the utilization rate of the microwave coupling agent is improved by the innovation, meanwhile, the preparation process is simple, and the energy is fully utilized; the problem that a large amount of harmful flue gas needs to be purified in an traditional sintering technology is solved, the industrialization process of incineration fly ash microwave sintering is promoted, and the method is particularly suitable for the fly ash harmless treatment which is taken incinerationfly ash ceramsite as a purpose..

Owner:TIANJIN CHENGJIAN UNIV

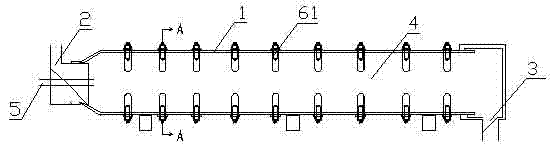

Decomposition equipment for crushed coal and pulverized coal

InactiveCN102295939AEasy maintenanceDecreased chance of unignitedElectrical coke oven heatingCombustible gas coke oven heatingThermodynamicsProcess engineering

The invention discloses a decomposition equipment for crushed coal and pulverized coal, which comprises a horizontally sealed rotary kiln body with a material inlet and a material outlet, a heating mechanism is arranged on the kiln wall of the kiln body, and the heating mechanism is connected The pulverized coal and pulverized coal propulsion and decomposition channels formed between the walls of the kiln body, the coal decomposition gas collection pipes connected with the pulverized coal and pulverized coal promotion and decomposition channels are arranged on the kiln body, and the control part of the heating mechanism is set on the kiln wall Externally, the heating part is set inside the kiln wall. The control and detection part is set outside the kiln wall, and it is easy to accurately control the ignition effect and ignition state during the continuous contact with the flammable and explosive high-temperature coal decomposition gas. In addition, while better controlling the ignition quality and accuracy, the igniter, as a wearing part, is arranged outside the kiln wall for easy inspection and maintenance.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

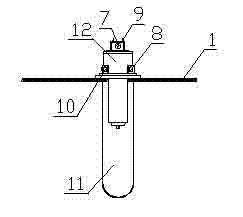

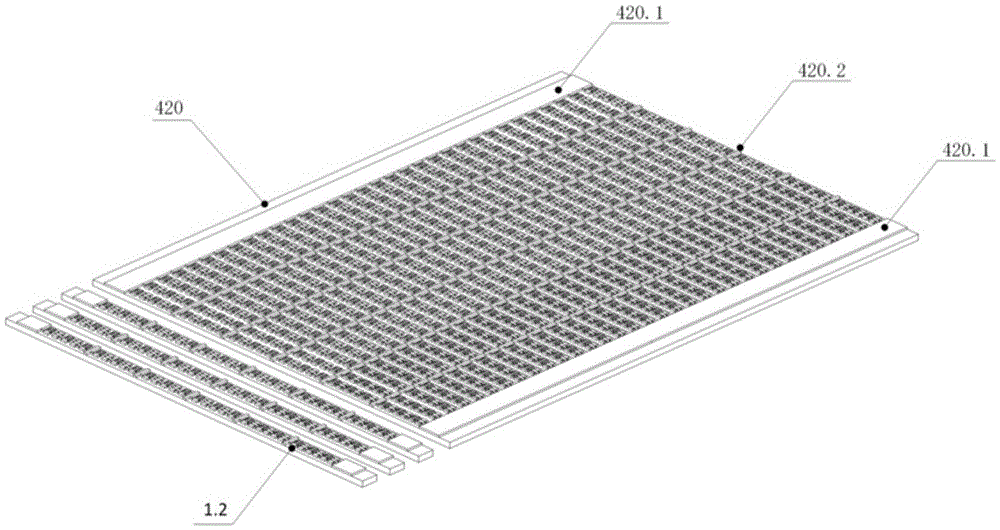

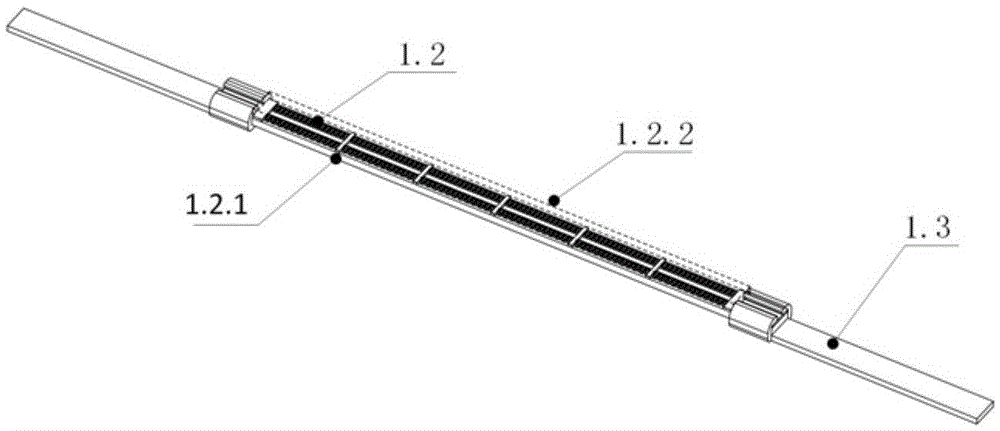

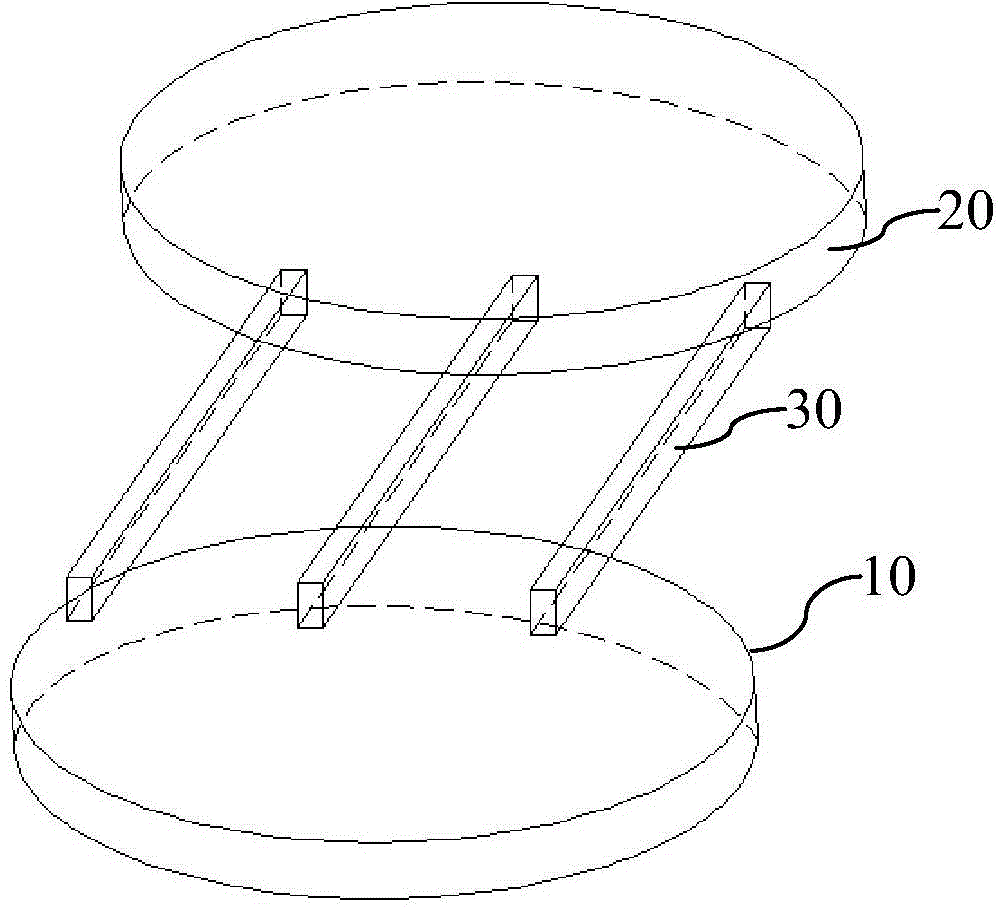

LED lamp filament assembly, method for forming LED lamp filament bulb and LED lamp filament bulb

ActiveCN105627124AImprove light extraction efficiencyLarge heat radiation areaPlanar light sourcesLighting heating/cooling arrangementsElectricityLight source

The invention discloses an LED lamp filament assembly, a method for forming an LED lamp filament bulb and the LED lamp filament bulb. The LED lamp filament assembly comprises one or more LED lamp filaments (1.1) with the two ends provided with electric connecting terminals (1.3). The electric connecting terminals (1.3) at the two ends of each LED lamp filament (1.1) are connected with two heat conduction and electricity conduction terminal supports (1.4). According to the LED lamp filament assembly, the light emitting rate of an LED can be increased, and the heat dissipation efficiency can be improved. According to the method for forming the LED lamp filament bulb and the LED lamp filament bulb, the limitation that an existing LED lighting lamp needs a radiator can be avoided, a large-power LED lamp filament lamp light source can be achieved, a light source of an existing large-power lighting product can be directly replaced, and lamps do not need to be replaced.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

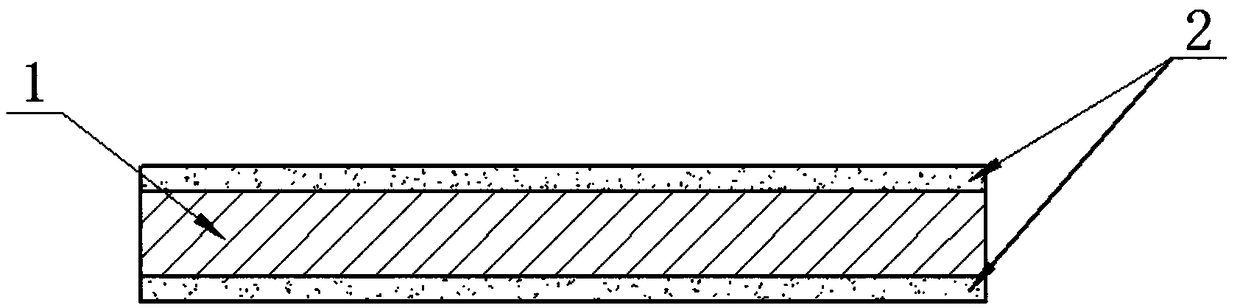

Light reflecting glass mirror and manufacturing method thereof

InactiveCN104591528AThe preparation method is safeReduce self-weight deformationMirrorsGlass reforming apparatusEngineeringThermal radiation

The invention discloses a light reflecting glass mirror and a manufacturing method thereof, wherein the manufacturing method comprises the following steps: S1, providing a plurality of semifinished panels and a plurality of semifinished rib plates; S2, using two semifinished panels respectively as a bottom plate and a top plate of the light reflecting glass mirror, using a plurality of semifinished rib plates as rib plates of the light reflecting glass mirror, and processing the bonding surfaces of the rib plates; S3, coating glass powder on the bonding surfaces in a clearance type manner, premounting the rib plates between the bottom plate and the top plate according to the distribution of the bonding surfaces, and removing redundant glass powder; S4, sending the bottom plate, the top plate and the rib plates, which are premounted, in a heating furnace, heating the heating furnace to a temperature which is 9-10 degree higher than the fusion point of the glass powder, keeping the temperature for at least 10 minutes, and after heating, cooling the heating furnace to drop the temperature so as to obtain the light reflecting glass mirror. The manufacturing method disclosed by the invention is safer, the manufactured light mirror has the characteristics that the self-weight deformation of the reflecting mirror, the thermal resistance in the thickness direction, and the deformation caused by temperature gradient are reduced, and the thermal radiation area of the reflecting mirror is enlarged.

Owner:SUZHOU UNIV

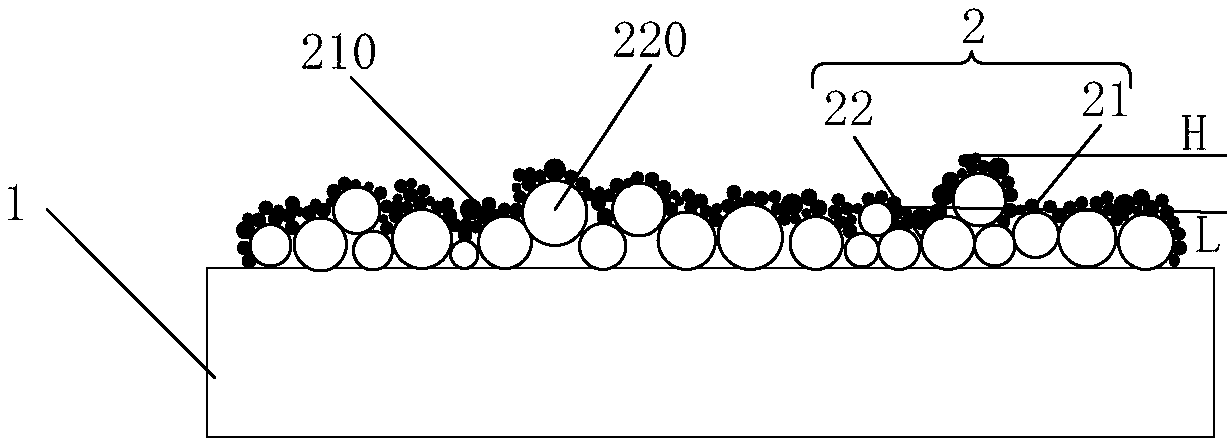

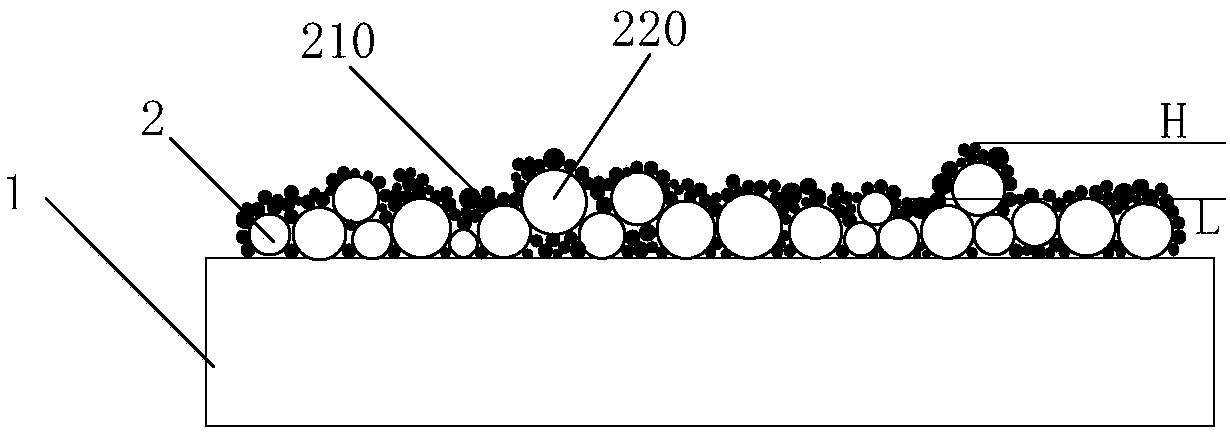

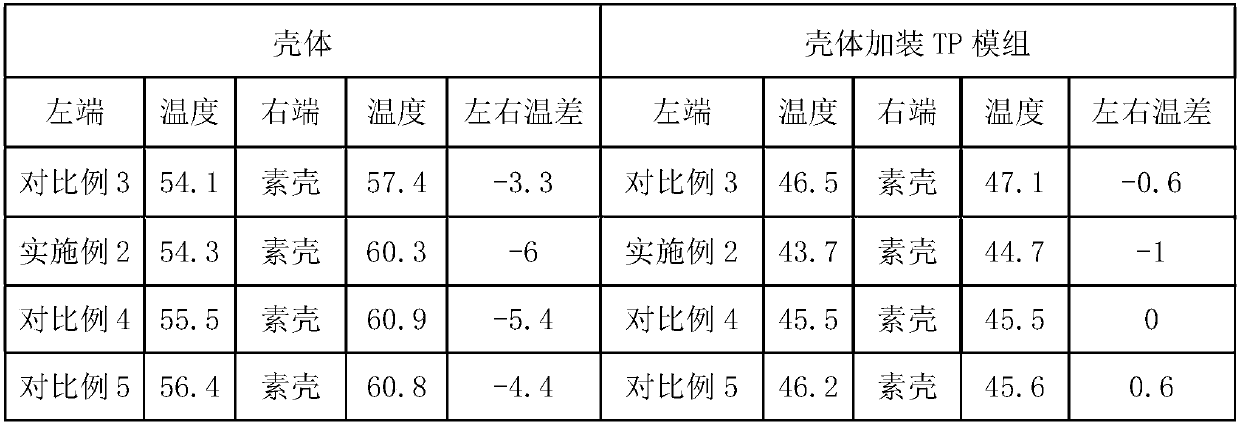

Shell of terminal equipment and processing method of shell

InactiveCN110621135AImprove cooling effectFast heat conductionModifications by conduction heat transferTerminal equipmentMetal particle

The invention provides a shell of terminal equipment and a processing method of the shell. The shell comprises a shell body and a heat conduction layer sprayed on a surface of the shell body, whereinnano carbon particles and heat conduction metal particles are contained in the heat conduction layer, and a surface of the heat conduction layer is provided with an uneven heat dissipation microstructure. The nano carbon particles have excellent heat conduction and heat radiation performance, the heat conduction performance is mainly reflected in heat diffusion transfer, the heat diffusion speed of the nano carbon particles is larger than or equal to 200 mm<2> / S, a heat radiation coefficient is 0.92-0.95, the nano carbon particles have excellent heat conduction performance, moreover, the carbon nanoparticles can form a continuous heat conduction channel on the surface of the shell after being dried, so heat conduction performance can be enhanced, and the heat can be conducted out more quickly. The particle size of the heat conduction metal particles is large, the nano carbon particles and the heat conduction metal particles can form the uneven heat dissipation microstructure on the surface of the shell body, the heat radiation area can be increased, and thereby heat dissipation performance of the heat conduction layer is further improved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

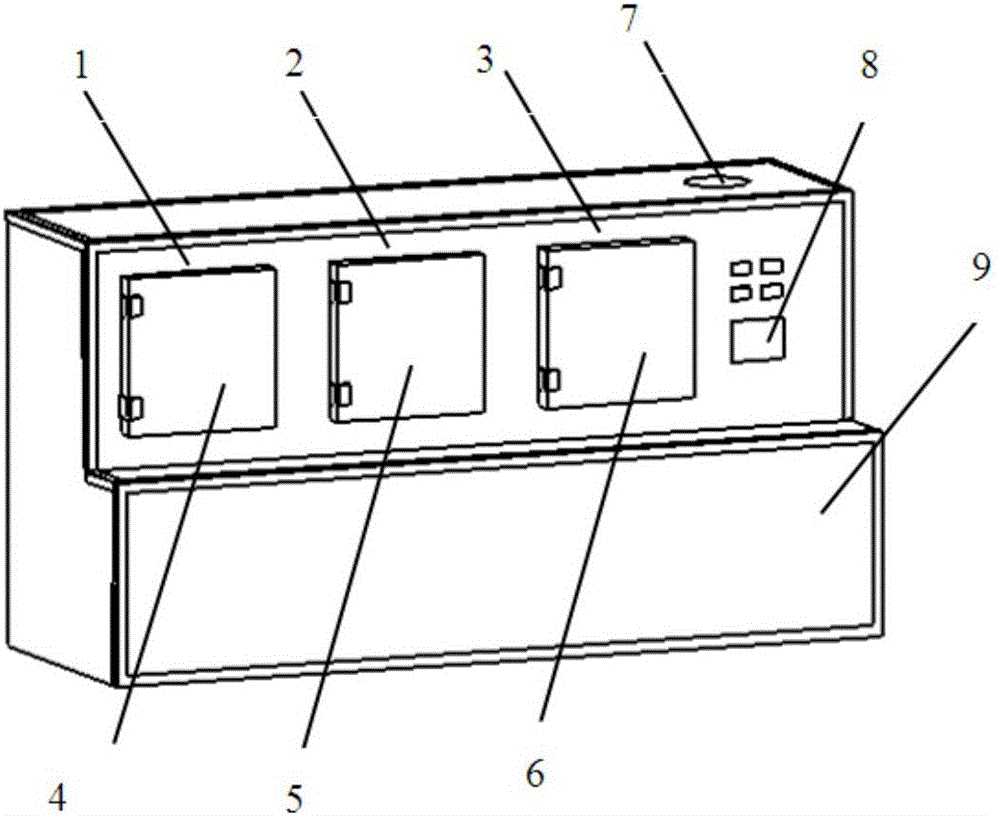

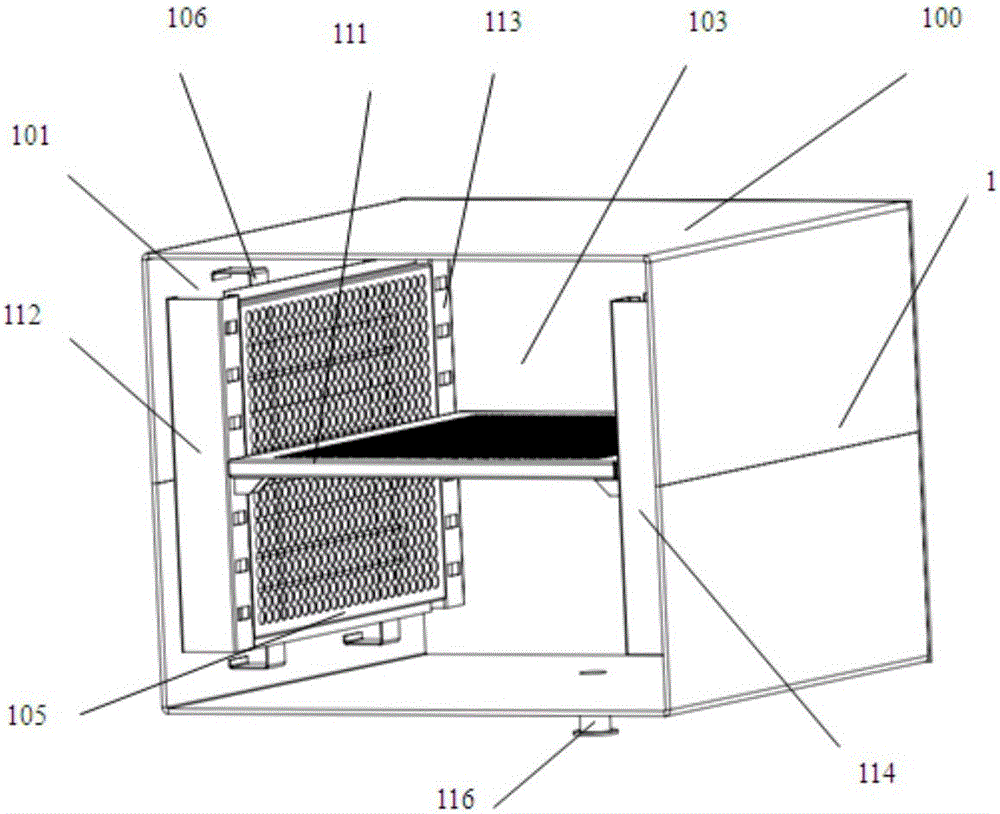

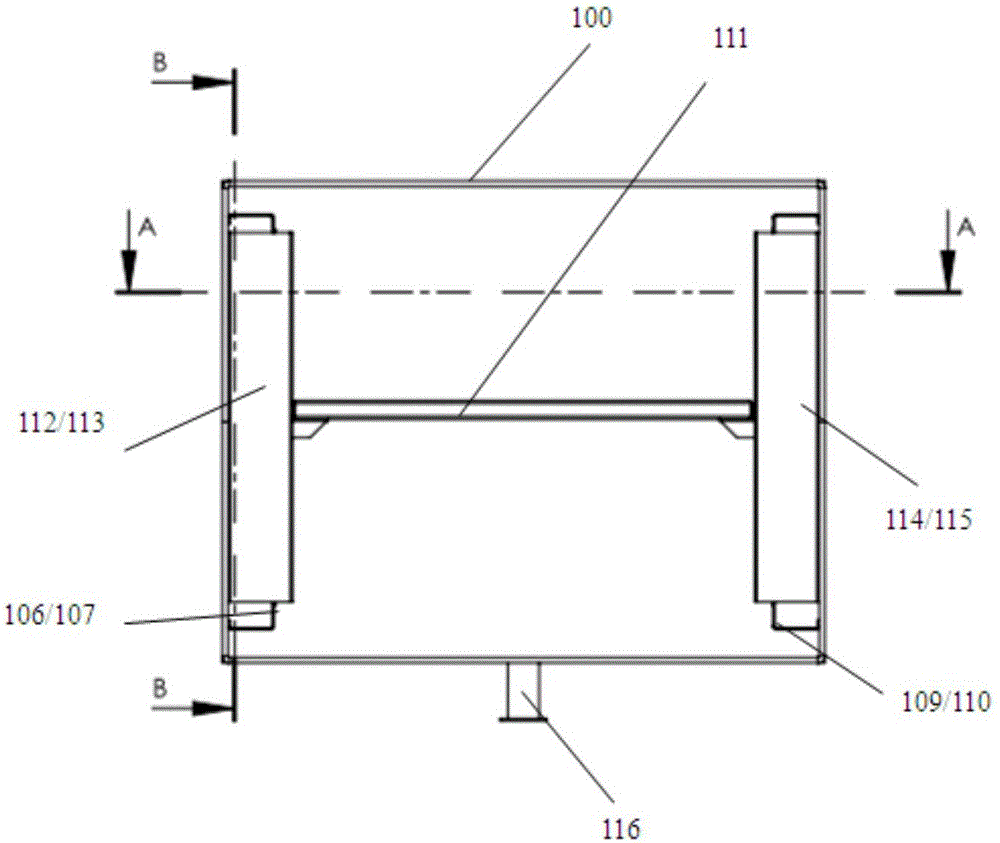

Independently controllable high-temperature equipment provided with multiple vacuum cavities

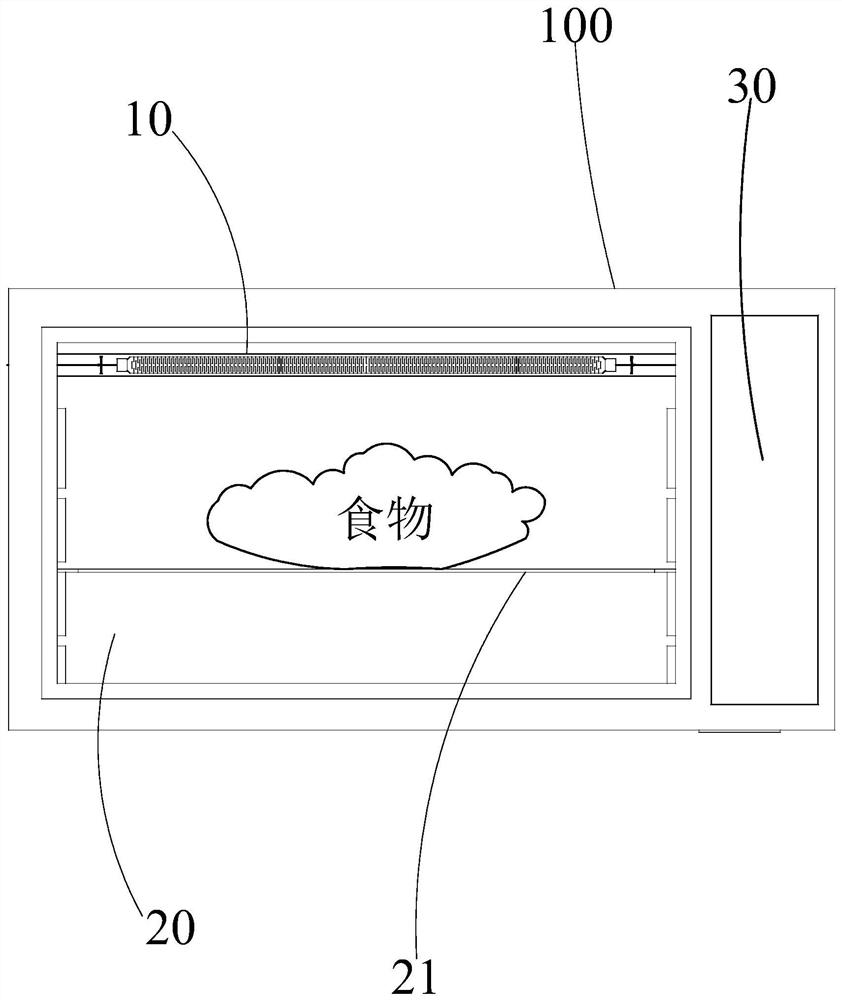

InactiveCN106586282ALarge heat radiation areaShort vacuum timePackaging under vacuum/special atmosphereContainers for heating foodVacuum pumpingElectromagnetic valve

The invention discloses independently controllable high-temperature equipment provided with multiple vacuum cavities. The independently controllable high-temperature equipment provided with the multiple vacuum cavities comprises the first vacuum cavity, the second vacuum cavity, the third vacuum cavity, a first sealing door, a second sealing door, a third sealing door, a vacuum-pumping system, a display control system and a cabinet body, wherein the first vacuum cavity, the second vacuum cavity and the third vacuum cavity have the same constitution; each vacuum cavity comprises a left-side heat radiation chamber, a right-side heat radiation chamber and a work chamber positioned between the left-side heat radiation chamber and right-side heat radiation chamber; the vacuum-pumping system consists of a molecular pump, a forepump, a prepump and a vacuum electromagnetic valve; one set of vacuum-pump system can vacuumize the plurality of cavities; the prepump is used for performing first-state vacuumization on the vacuum cavities; the forepump is used for maintain the vacuumizing work of the molecular pump and also can serve as the prepump when necessary; the vacuum time of the whole system is short; and independently controllable high-temperature equipment provided with the multiple vacuum cavities can realize that the plurality of vacuum cavities can be independently controlled and display, can realize single stop and restart operation, and realizes non-interference truly.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

Drying heating method for production resumption of coke dry quenching furnace after medium repair

The invention discloses a drying heating method for production resumption of a coke dry quenching furnace after medium repair and is mainly intended to solve the technical problem that the use of the gas drying heating process in the production resumption of an existing coke dry quenching furnace after medium repair results in long drying time, high gas consumption, high drying cost and difficulty in gas drying equipment assembly and disassembly. A coke dry quenching furnace under production resumption after medium repair is dried with heat from red coke that is at 1000 DEG C and that is pushed out of a coke oven, and quick heating is achieved for the coke dry quenching furnace under production resumption after medium repair; compared with existing gas drying heating processes, the drying heating method is lower in drying gas consumption, shorter in production resumption time of the coke dry quenching furnace after medium repair, and higher in production efficiency of the coke dry quenching furnace. The drying heating method is applicable to the drying of a coke dry quenching furnace for production resumption after medium repair, while a pre-storage segment of a coke dry quenching furnace is under replacement and a cooling segment is not repaired.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

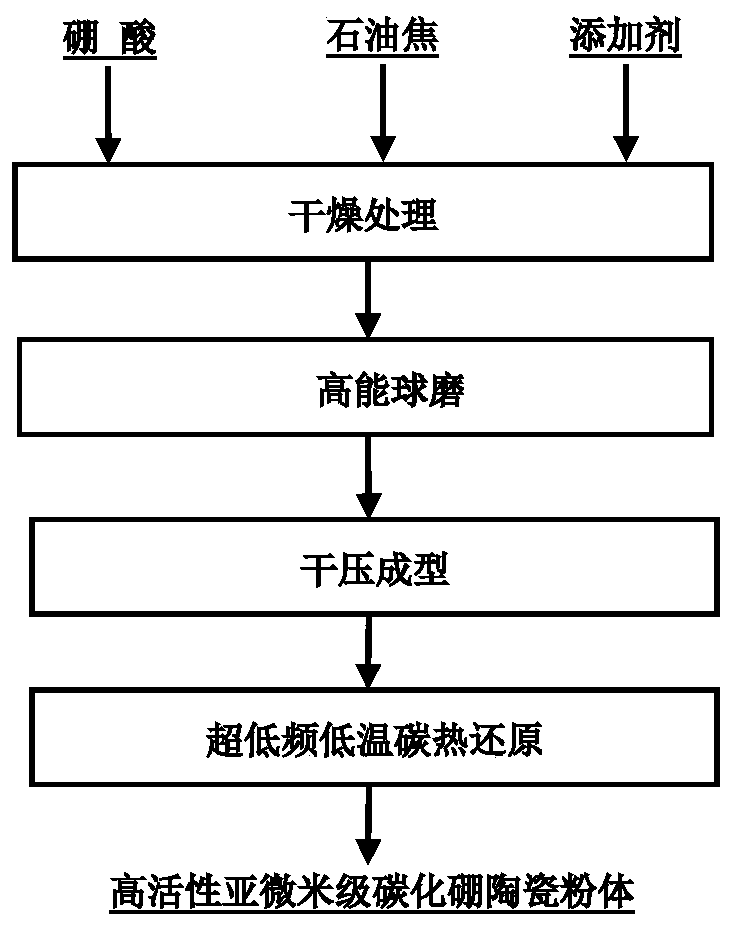

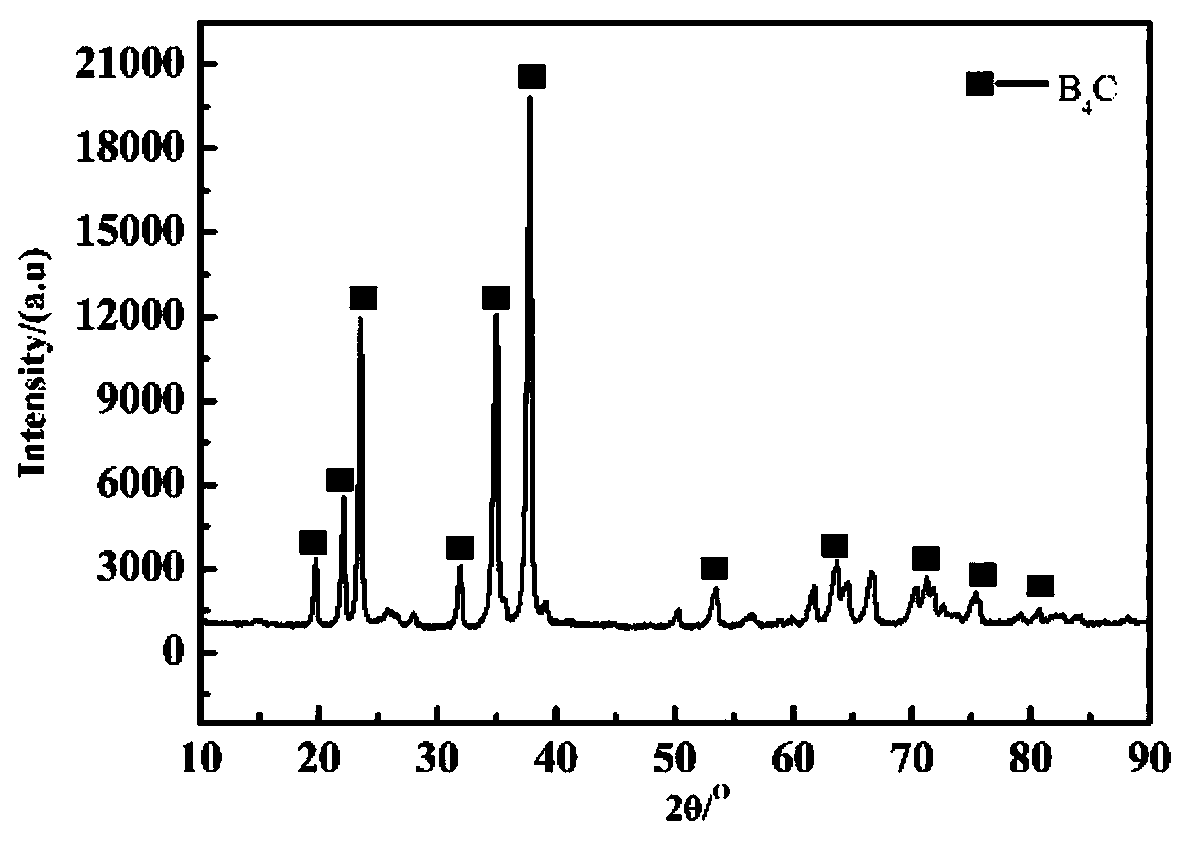

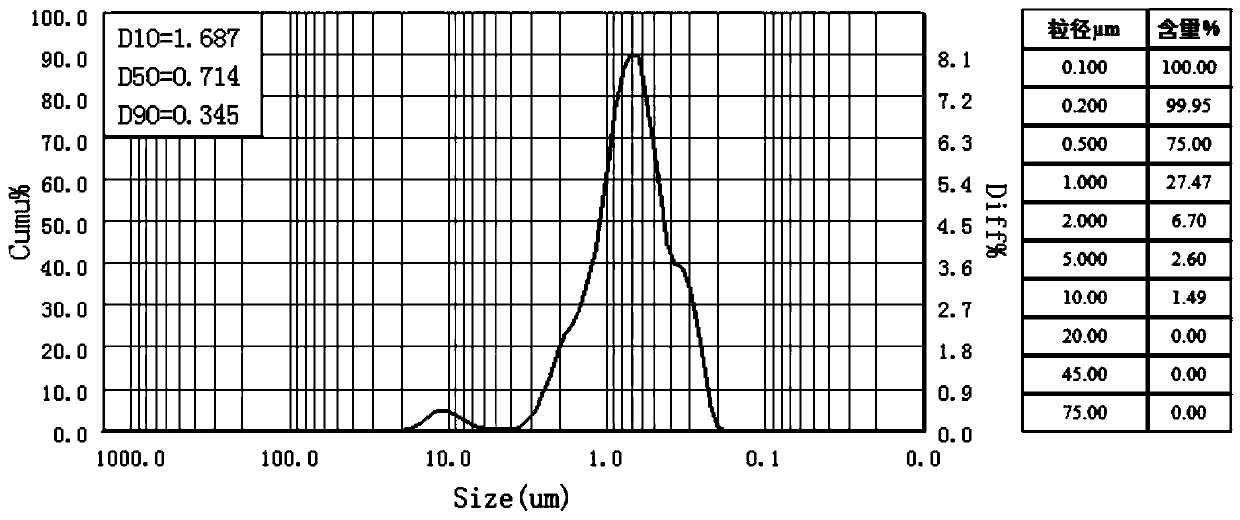

High-activity submicron boron carbide ceramic powder and low-temperature in-situ preparation method thereof

ActiveCN111470868ARaise the reaction temperatureLow reaction temperatureChemical industryCeramic sinteringHeating furnace

The invention provides a high-activity submicron boron carbide ceramic powder and a low-temperature in-situ preparation method thereof, and belongs to the field of preparation of boron carbide powder.The preparation method comprises the following steps: proportioning boric acid, petroleum coke and a rare earth oxide additive, drying, carrying out high-energy ball milling, crushing, and dry-pressmolding, and carrying out low-temperature carbon thermal reduction in an ultralow-frequency heating furnace to in-situ prepare the high-activity submicron boron carbide ceramic powder. According to the method, preparation and crushing are integrated, submicron B4C powder can be directly prepared, and subsequent tedious crushing and purifying are not needed. The rare earth oxide can reduce the carbon thermal reduction temperature, inhibit the growth of B4C grains and prevent the coarsening of grains. Meanwhile, due to the addition of the rare earth oxide, a second phase for promoting subsequentB4C ceramic sintering can be generated through an in-situ reaction, and the sintering activity of the ceramic powder is greatly improved. Compared with the prior art, the method has the advantages oflow reaction temperature, short reaction time, low cost, environment friendliness, energy conservation, consumption reduction and the like, and the process is simple and feasible and can be suitablefor industrial large-scale popularization.

Owner:JIANGSU UNIV

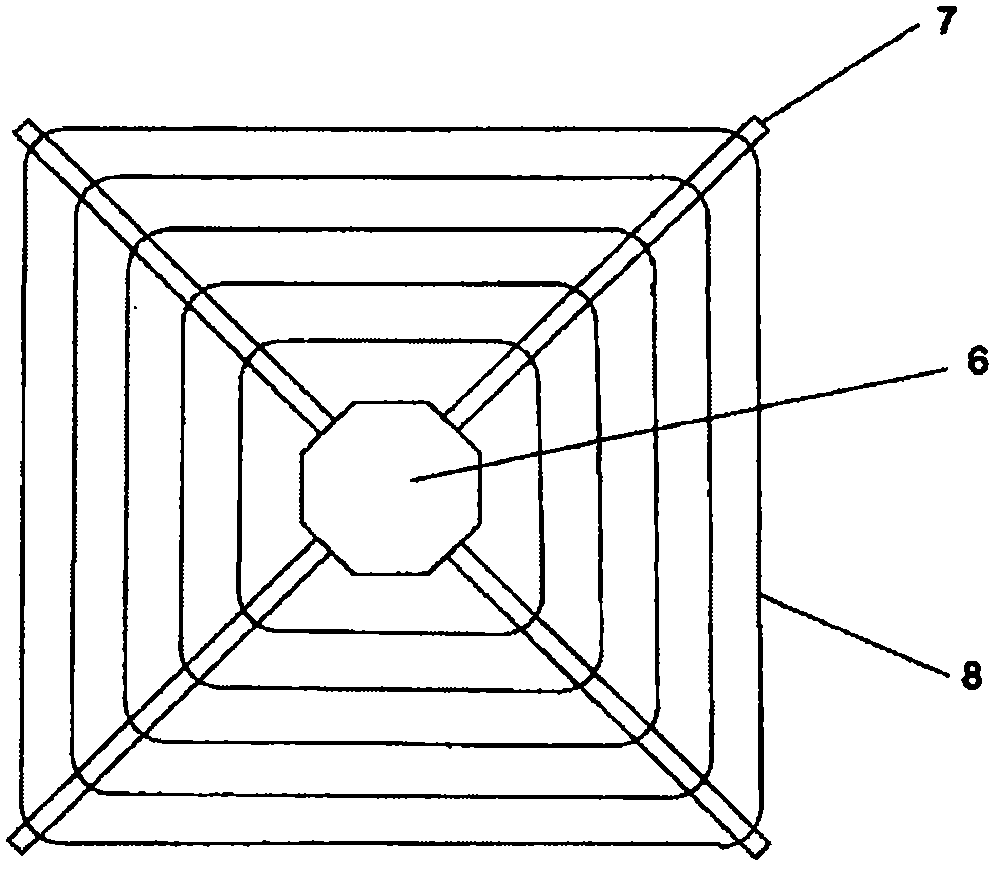

Far infrared reflector of integrated structure and manufacturing method of far infrared reflector

ActiveCN104848339AReduce CODReduce online operationsLighting and heating apparatusElectric heating systemEngineeringFar infrared

The invention relates to a far infrared reflector of an integrated structure. The far infrared reflector comprises a reflector mounting surface, a reflector, two reflector side surfaces, heating tube mounting holes, a fastener and a thermal insulating board; the fastener is used for limiting a heating tube in the heating tube mounting holes from moving outwards; the heating tube mounting holes are formed in the two reflector side surfaces in a pair, respectively; the connection line of the pair of heating tube mounting holes is parallel to the center line of the cambered surface structure of the reflector; the reflector mounting surface, the reflector, the two reflector side surfaces and the heating tube mounting holes are of an integrated structure molded by pressing. The reflector of the integrated structure is capable of saving the operation steps, converting complexity into simplicity and improving the production efficiency; during assembly, the reflector is taken out, the heating tube is mounted, positioned and fixed by use of the fastener, and then a fastening leg is pressed flatly, and the mounting is completed.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

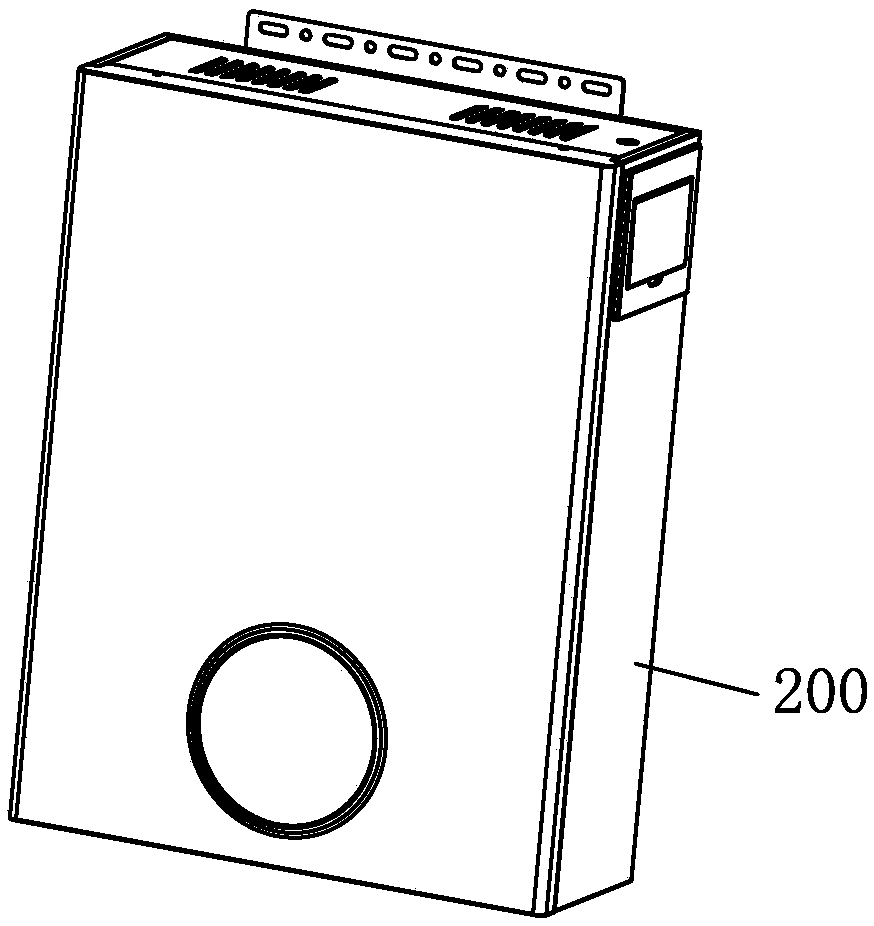

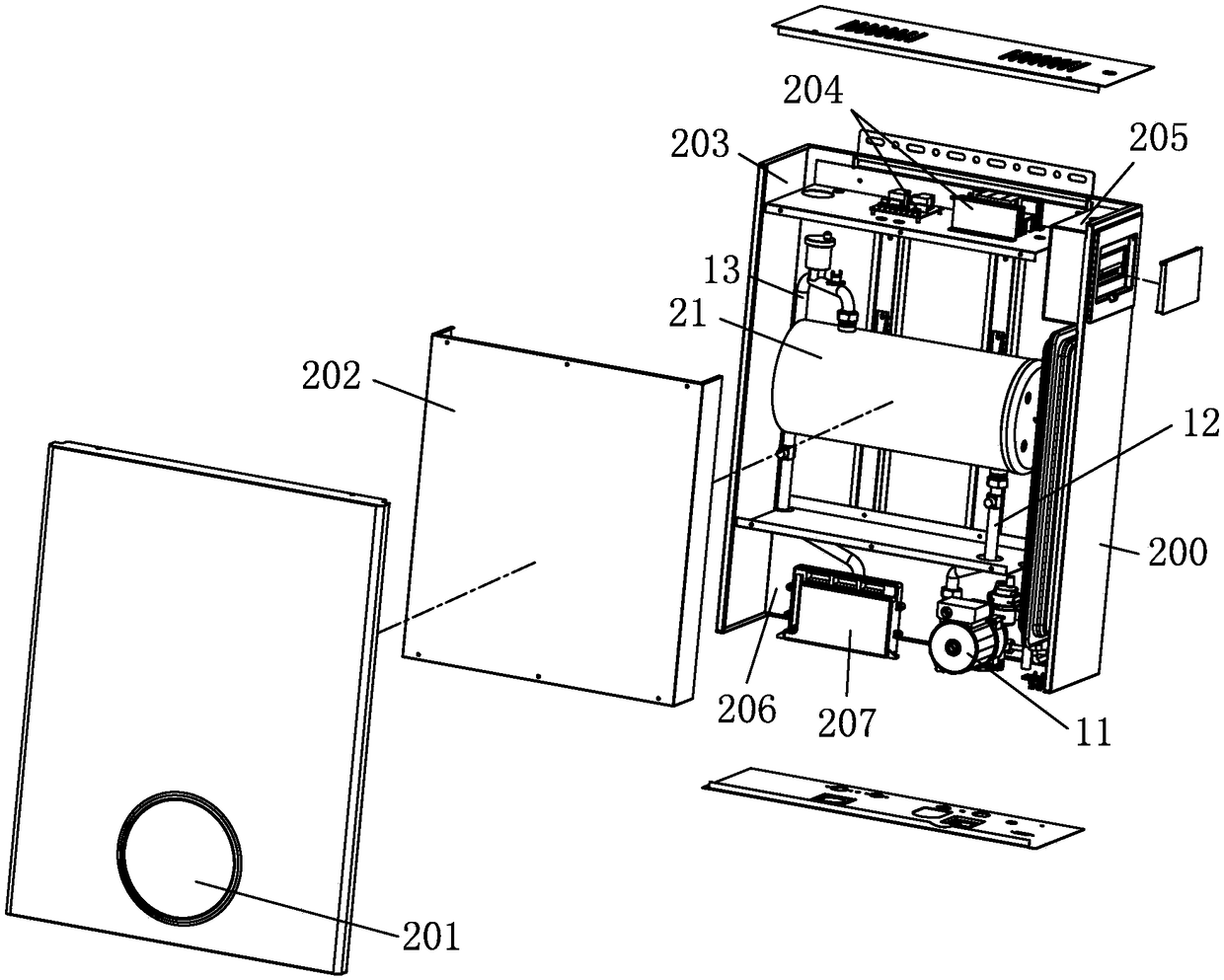

Light wave wall-hanging stove

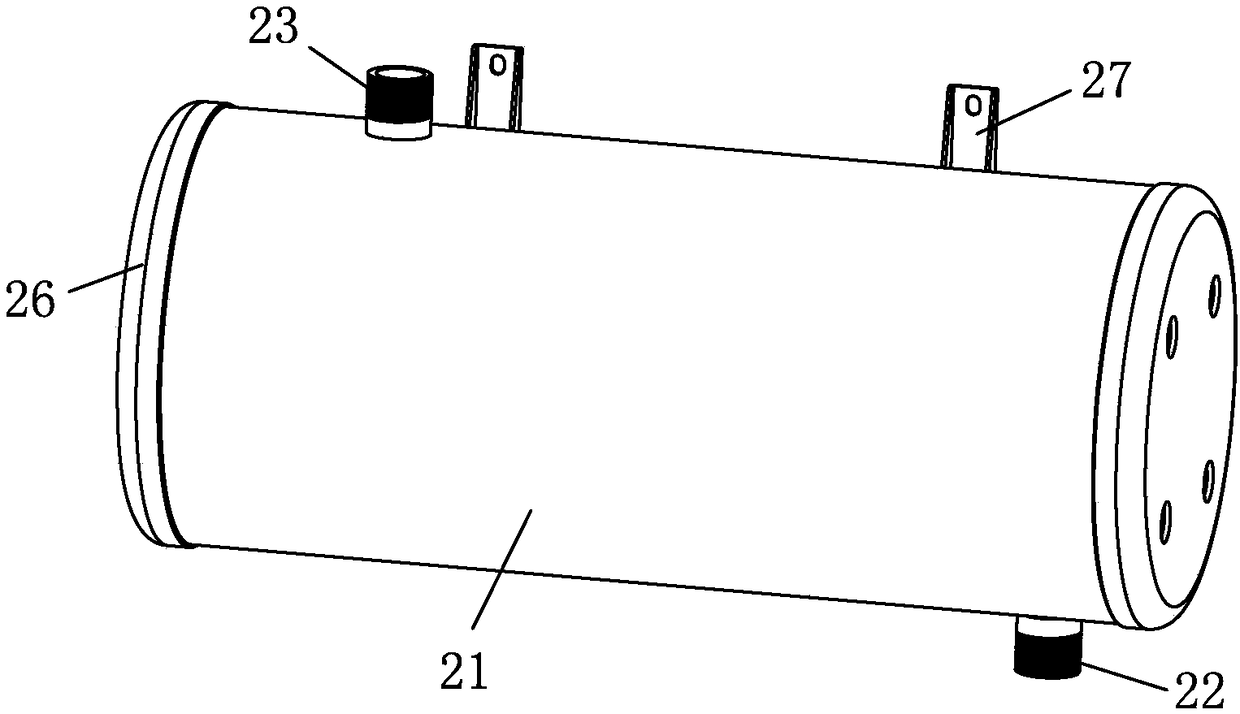

PendingCN108518854AAchieve heatingThe heating water tank is set for water circulationWater heatersElectricityInlet valve

The invention discloses a light wave wall-hanging stove which comprises a stove body. The stove body is internally provided with a water inlet valve, a circulation pump, a water inlet pipe, an electrical heating water tank, a water outlet pipe and a water outlet valve which are sequentially connected to form a heating water way, a heating cavity for water circulation heating is formed inside a heating tank body, a water inlet communicating with the heating cavity and connected with the water inlet pipe is arranged at the lower portion, and a water outlet communicating with the heating cavity and connected with the water outlet pipe is arranged at the upper portion; a heating barrel is arranged in the heating tank body, a light wave heating tube is installed inside the heating barrel, heatgenerated when the light wave heating tube works is radiated to the surface of the heating barrel and is radiated to the interior of the heating tank body from the surface of the heating barrel, and water circulating in the heating cavity is heated. Heat generated when the light wave heating tube works is radiated to the surface of the heating barrel and is radiated outwards through the surface ofthe heating barrel, the water circulating in the heating cavity is heated, the light wave heating tube cannot be in contact with water due to blockage of the heating barrel, and true water and electricity separation is achieved.

Owner:广东卓菲特新能源科技有限公司

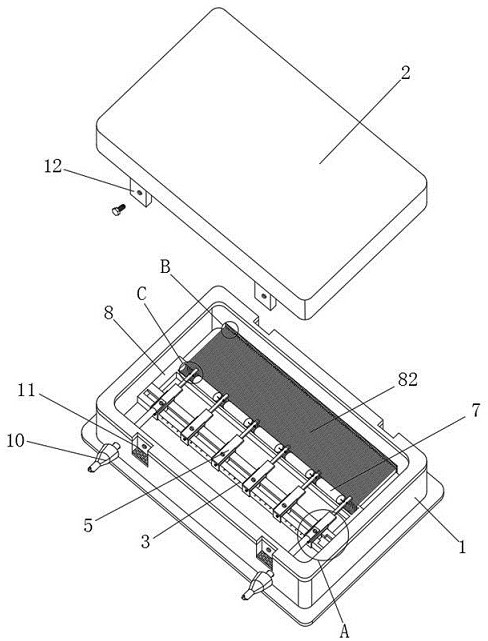

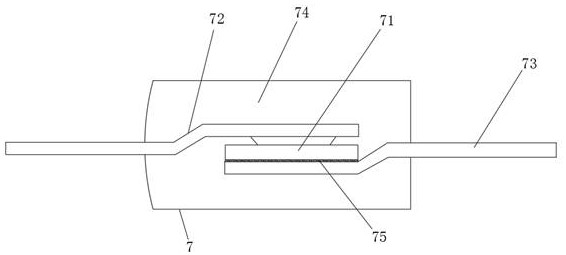

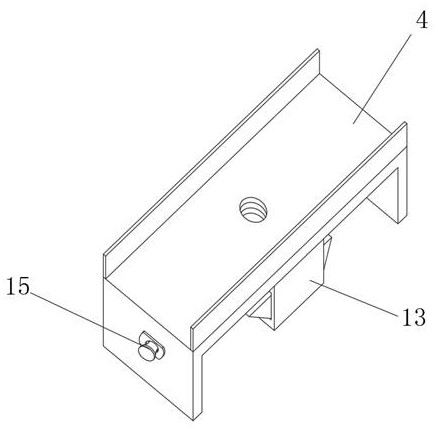

Bypass diode for solar junction box

PendingCN112104324AIncrease the areaIncrease cooling areaSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention discloses a bypass diode for a solar junction box, and belongs to the field of diodes. The diode comprises a box body, a box cover is fixedly connected to the top of the box body, a sliding rail is fixedly connected to the bottom of the inner wall of the box body, and six connecting seats are movably connected to the surface of the sliding rail. Connecting reeds are fixedly connectedto the tops of the six connecting seats, connecting pins are fixedly connected to the tops of the connecting reeds, a diode body is fixedly connected between every two adjacent connecting pins, two connectors are fixedly connected to one side of the box body, and leads are fixedly connected to one sides of the two connectors. According to the invention, chips are assembled in parallel with the leads, and semiconductor chips with larger sizes can be placed in the same boundary dimension so that rated power of a product is improved, an area of copper leads in the product is increased, a heat dissipation area of the chips is enlarged, and a failure rate of the product can be effectively reduced.

Owner:山东元捷电子科技有限公司

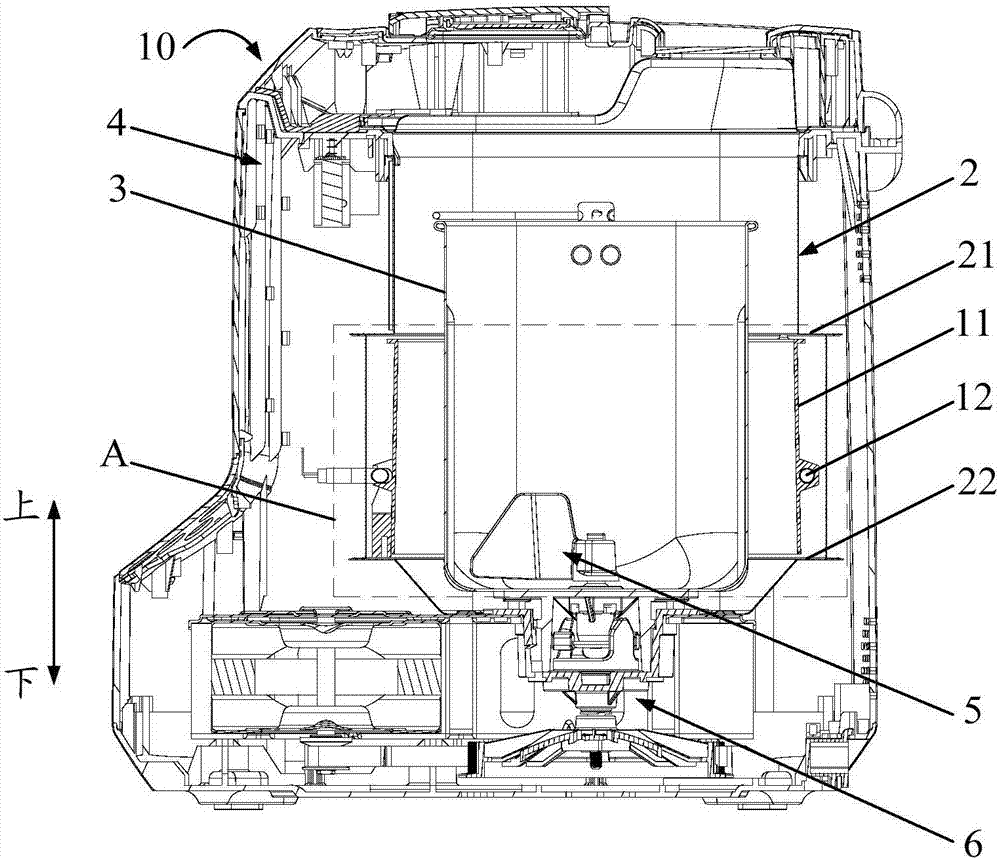

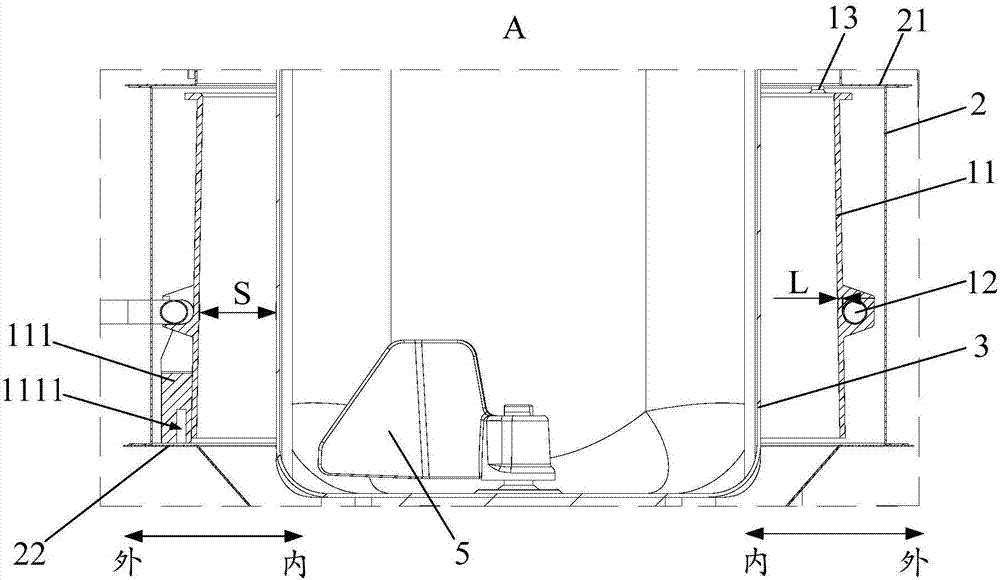

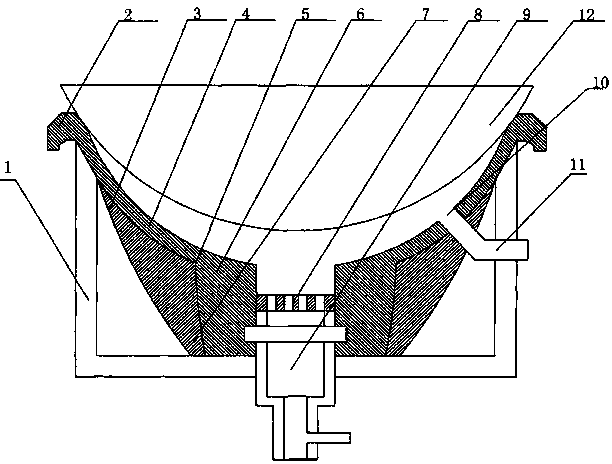

Cooking utensil

ActiveCN107280511ALarge heating areaEnsure heating uniformityBread-toastersElectric heatingEngineering

The invention provides a cooking utensil. The cooking utensil comprises a main engine, an inner container, a heat conduction shell and an electric heating part, wherein the main engine is provided with an outer container, the inner container is detachably installed in the outer container, the heat conduction shell is located in the outer container and is arranged at the outer side of the inner container in a sleeving mode, and the electric heating part is arranged on the heat conduction shell and is used for heating the heat conduction shell to make the temperature of the heat conduction shell rise and radiate heat to the inner container. According to the cooking utensil, the heat conduction shell is arranged at the outer side of the inner container in an encircle and sleeving mode, and in this way, the heating area of the inner container is increased; meanwhile, the heat on the heat conduction shell can be evenly transferred to the surface of the inner container corresponding to the heat conduction shell, thus the purpose that every corner of the surface of the inner container is uniformly heated is effectively guaranteed, and therefore the color and mouthfeel of food cooked in the inner container are improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Novel energy-efficient device for commercial stove

InactiveCN108343993APrevent spillageStop lossDomestic stoves or rangesLighting and heating apparatusThermal energyExhaust fumes

The invention discloses a novel energy-efficient device, and relates to the technical field of a cooker. The novel energy-efficient device comprises a cooking bench body, a sealing pot ring, furnaces,a heat gathering and storage heat-resistant radiation ring, flame energy-gathered rings, a full pre-mix energy-saving burner and a pot body. The pot body is disposed above the sealing pot ring, and the lower part of the sealing pot ring is connected with a cast steel furnace to form an integral furnace. The lower part of the integral furnace is disposed on the cooking bench body, and the heat gathering and storage heat-resistant radiation ring is disposed at the groove position of the integral furnace. The heat gathering and storage heat-resistant radiation ring is formed by integrating an inner layer and an outer layer through solvation, and the flame energy-gathered rings are disposed at the center of the bottom of a groove of the integral furnace. The full pre-mix energy-saving burneris disposed under the flame energy-gathered rings of the center of the bottom of the groove of the integral furnace. An independent exhaust gas passage opening is formed in the side surfaces of the integral furnace and the heat gathering and storage heat-resistant radiation ring, and the exhaust gas passage opening is connected with an exhaust fume passage of the cooking bench body. The novel energy-efficient device has reasonable design, novel structure, stable performance and convenient installation, and improves the heat energy utilization efficiency and saves the cooking time.

Owner:KUNSHAN FULING ENERGY USE

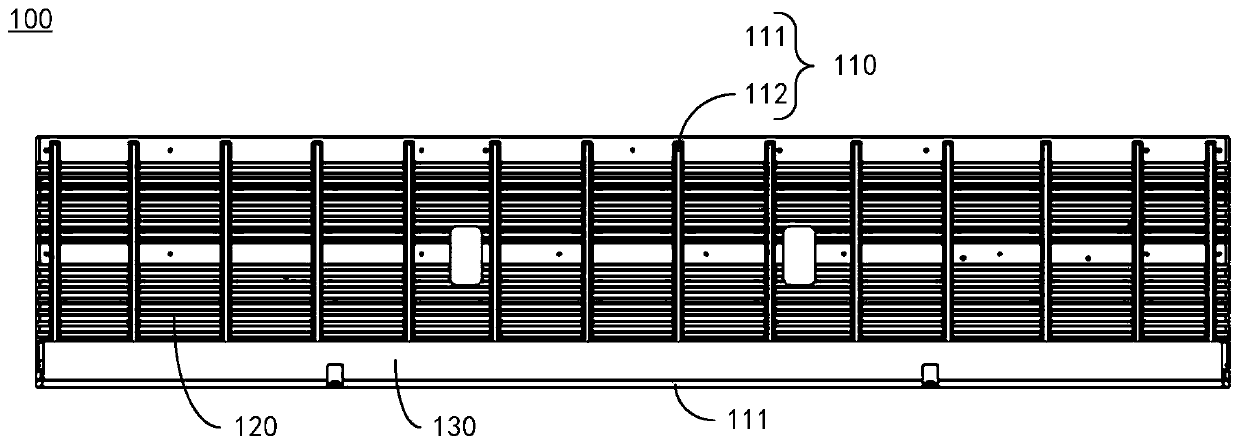

Heat dissipation assembly, backlight source assembly and display device

ActiveCN111565549AReduce aggregationFast conductionEnergy efficient computingCooling/ventilation/heating modificationsDisplay deviceMechanical engineering

The embodiment of the invention provides a heat dissipation assembly, a backlight source assembly and a display device. The heat dissipation assembly comprises a heat conduction structure and a heat dissipation structure, one side of the heat conduction structure is in heat conduction connection with a heat source, and the other side of the heat conduction structure is in heat conduction connection with one side of the heat dissipation structure. At least one side surface, far away from the heat conduction structure, of the heat dissipation structure is an anodized surface. The heat conductionconnection bridge is established between the heat source and the heat dissipation structure through the heat conduction structure, heat at the heat source can be rapidly conducted to the heat dissipation structure, and heat accumulation at the heat source is reduced; the heat dissipation structure is not in direct heat conduction connection with a heat source, so that the heat dissipation structure is flexibly arranged, and influence on the original structural design of the display product is greatly reduced; the anodized surface of the heat dissipation structure is provided with a large number of micropores, the heat radiation area can be increased, and therefore the heat radiation efficiency is improved.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

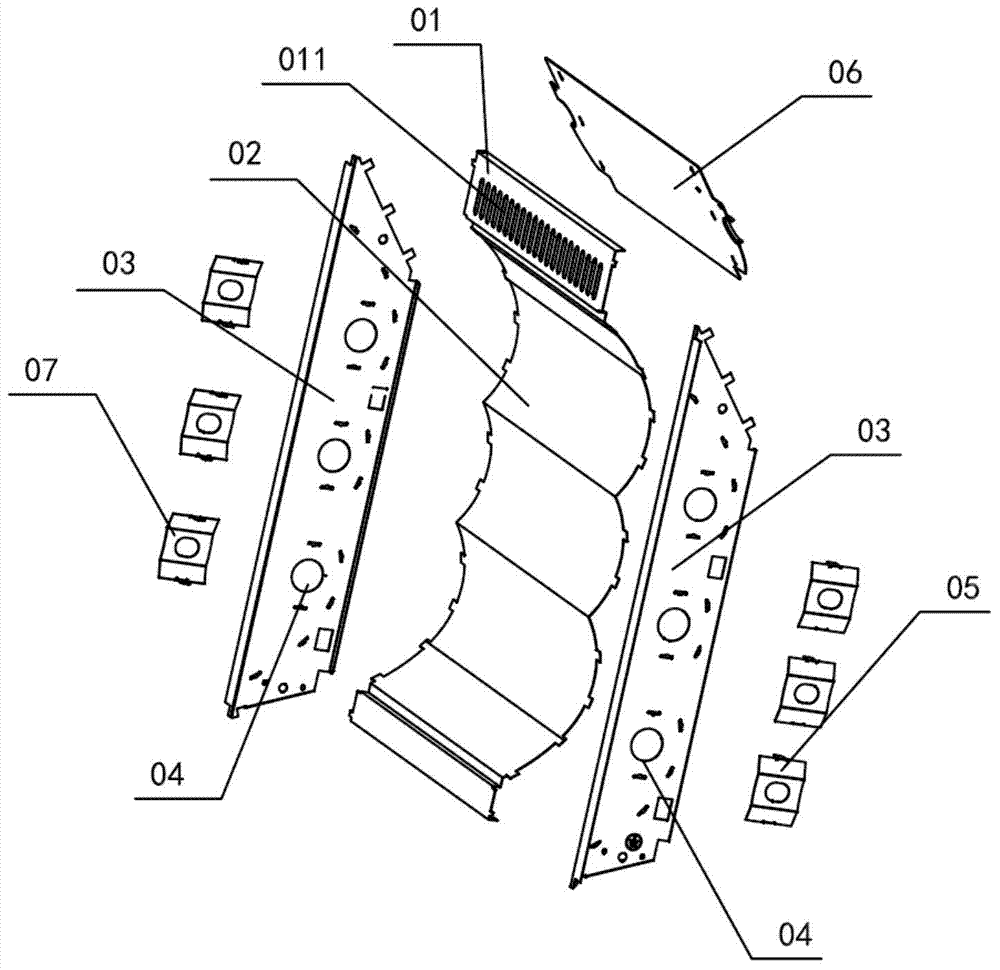

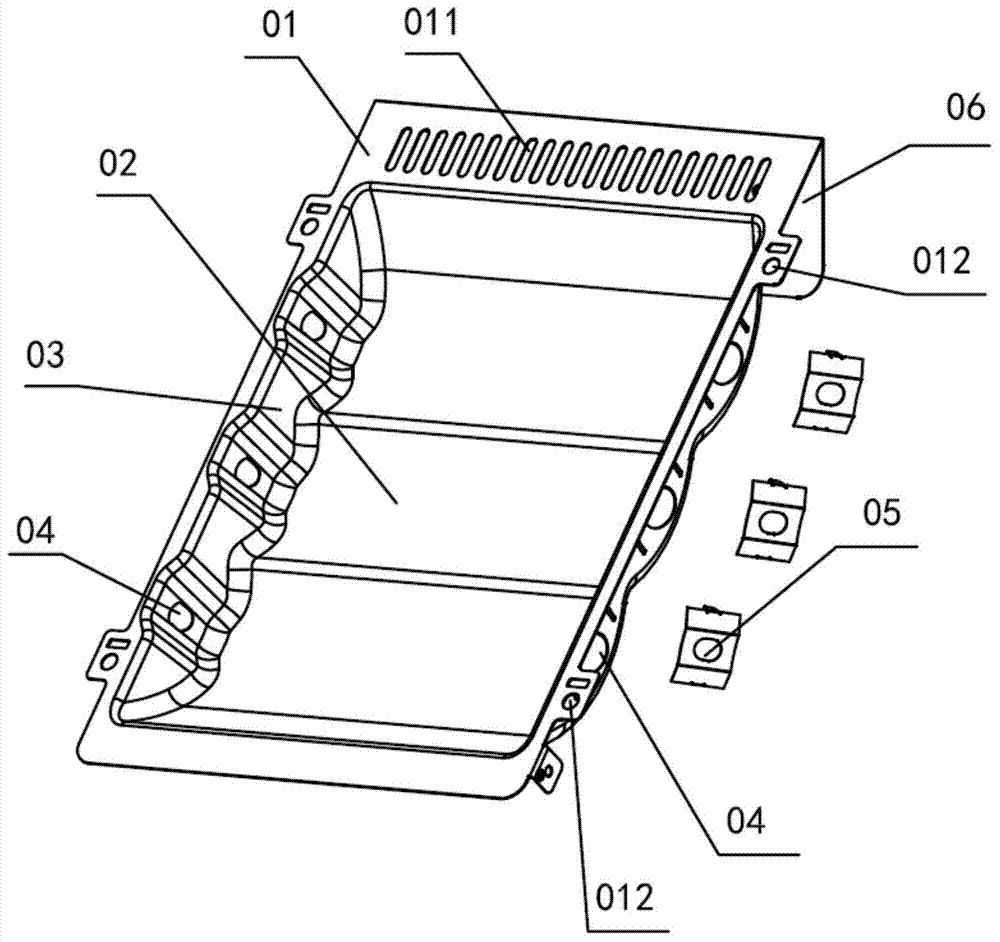

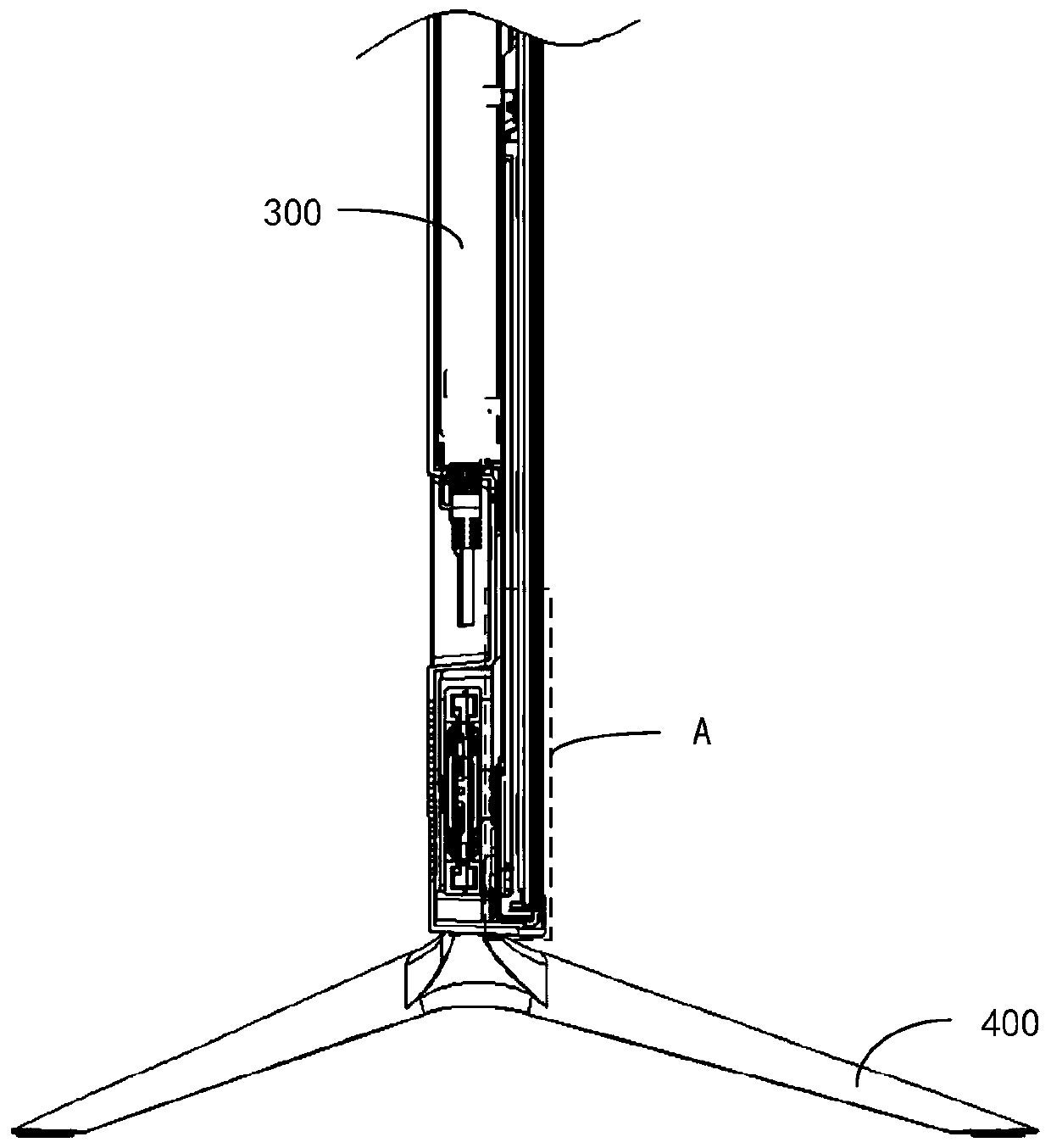

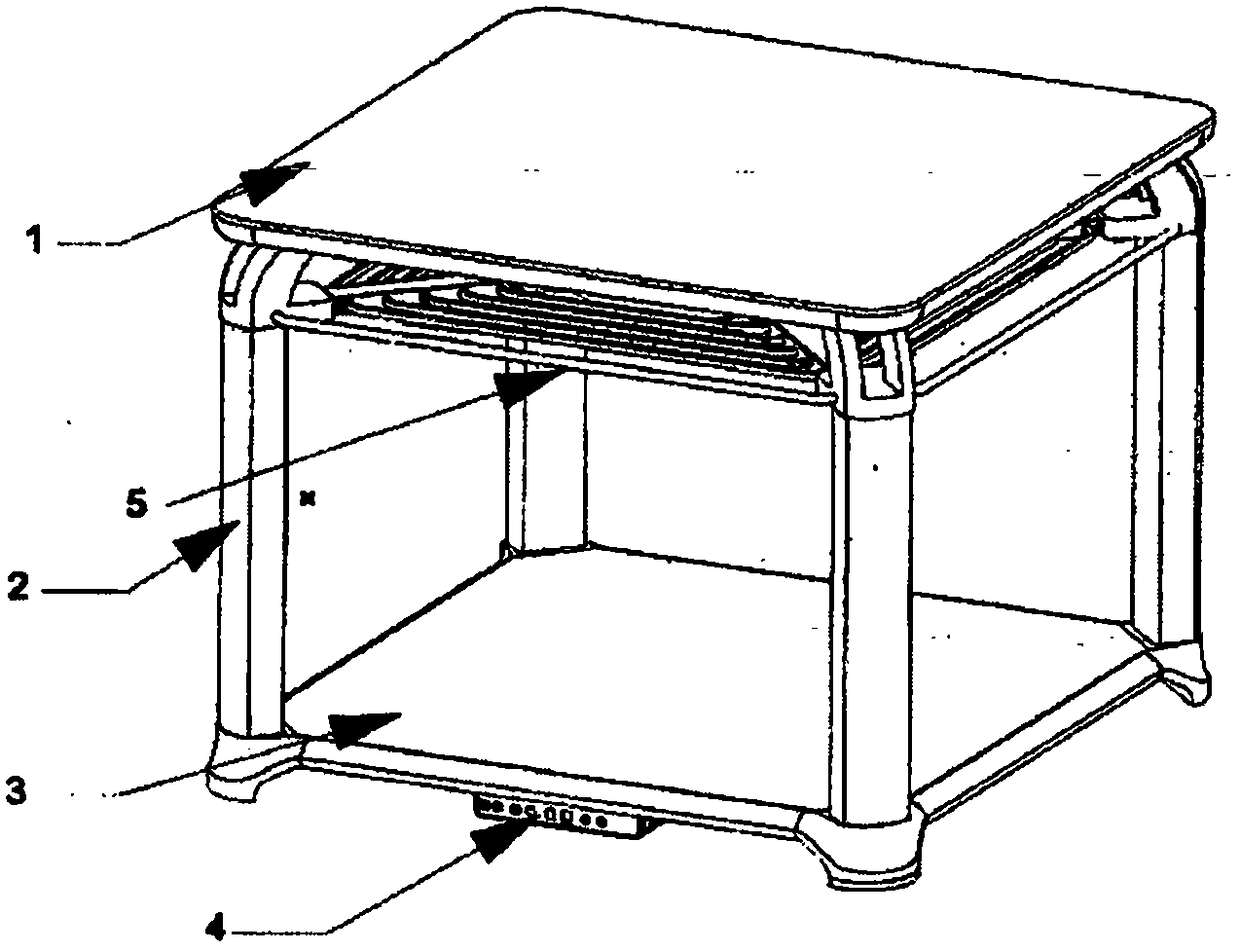

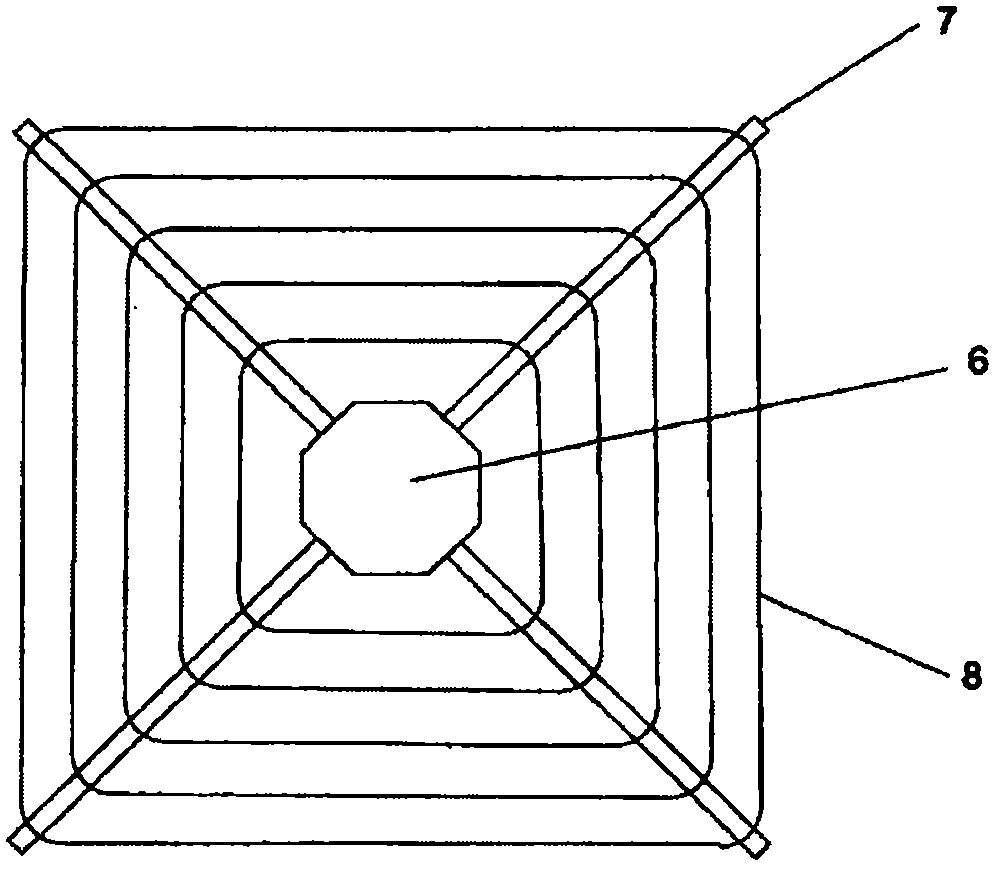

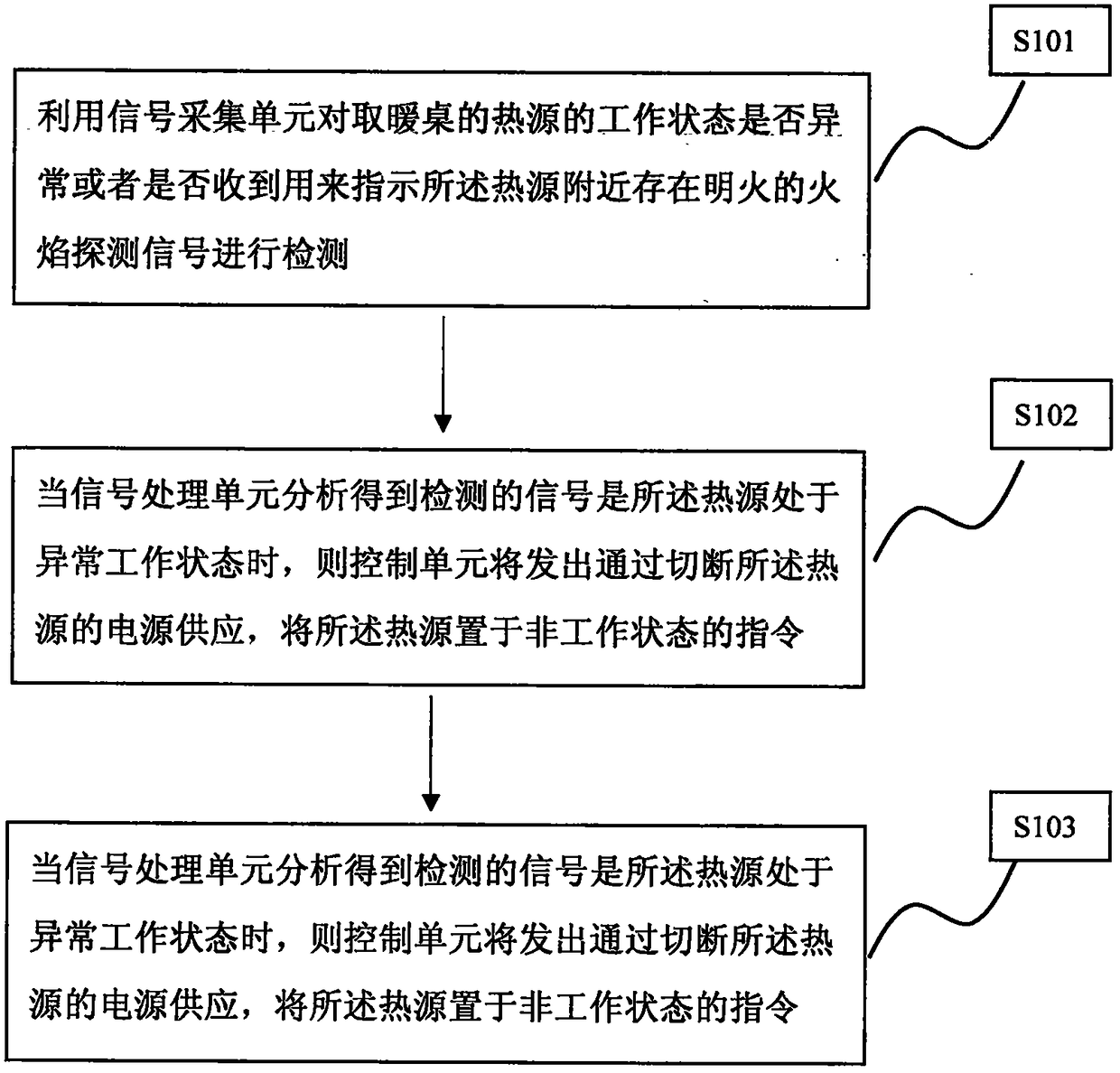

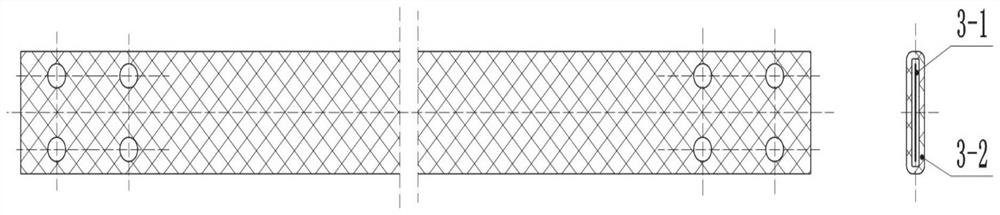

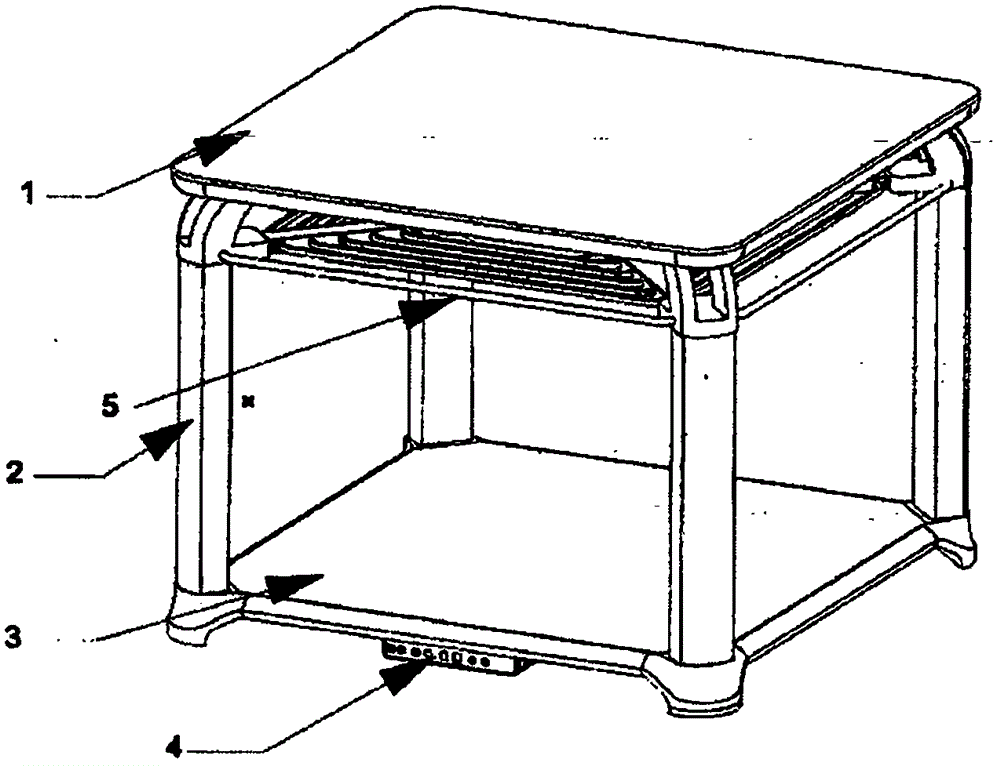

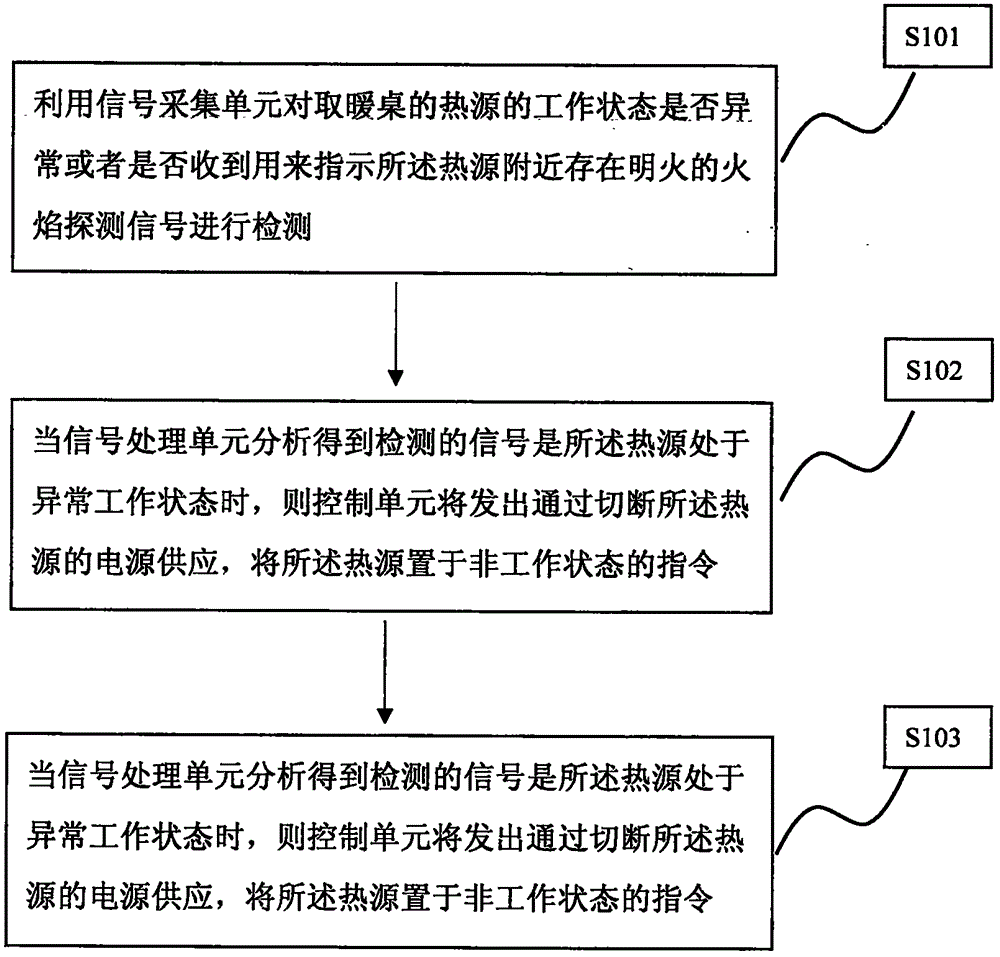

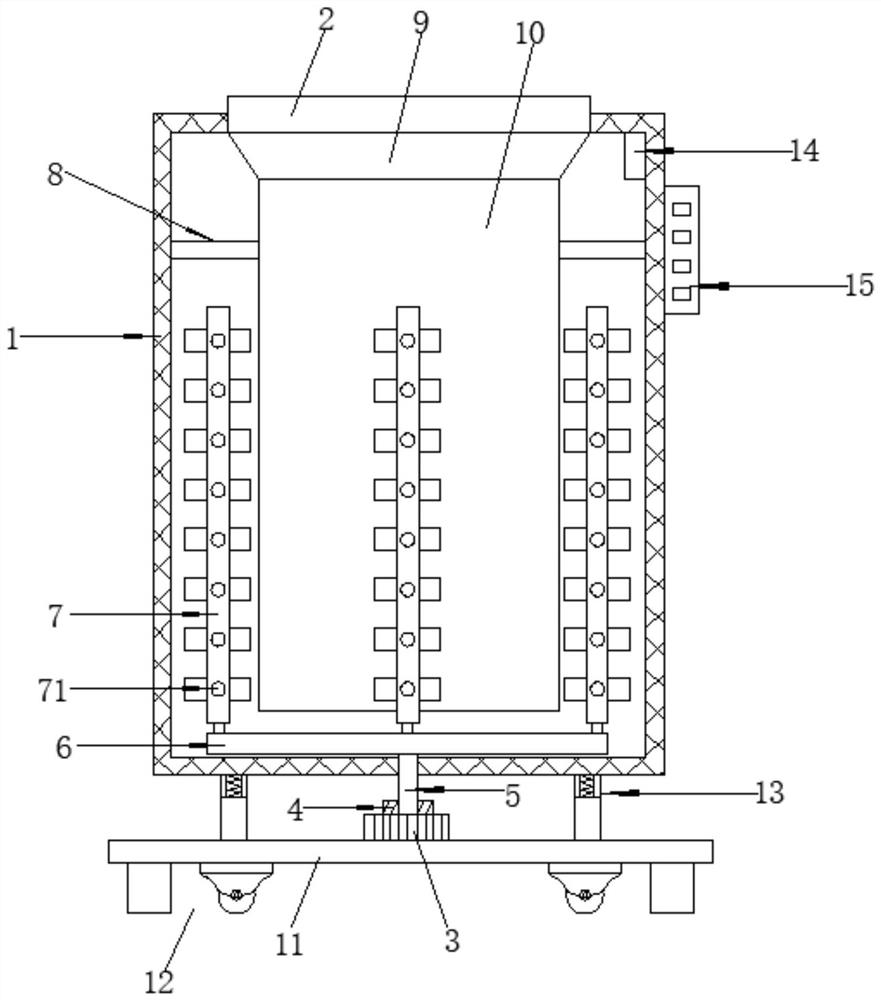

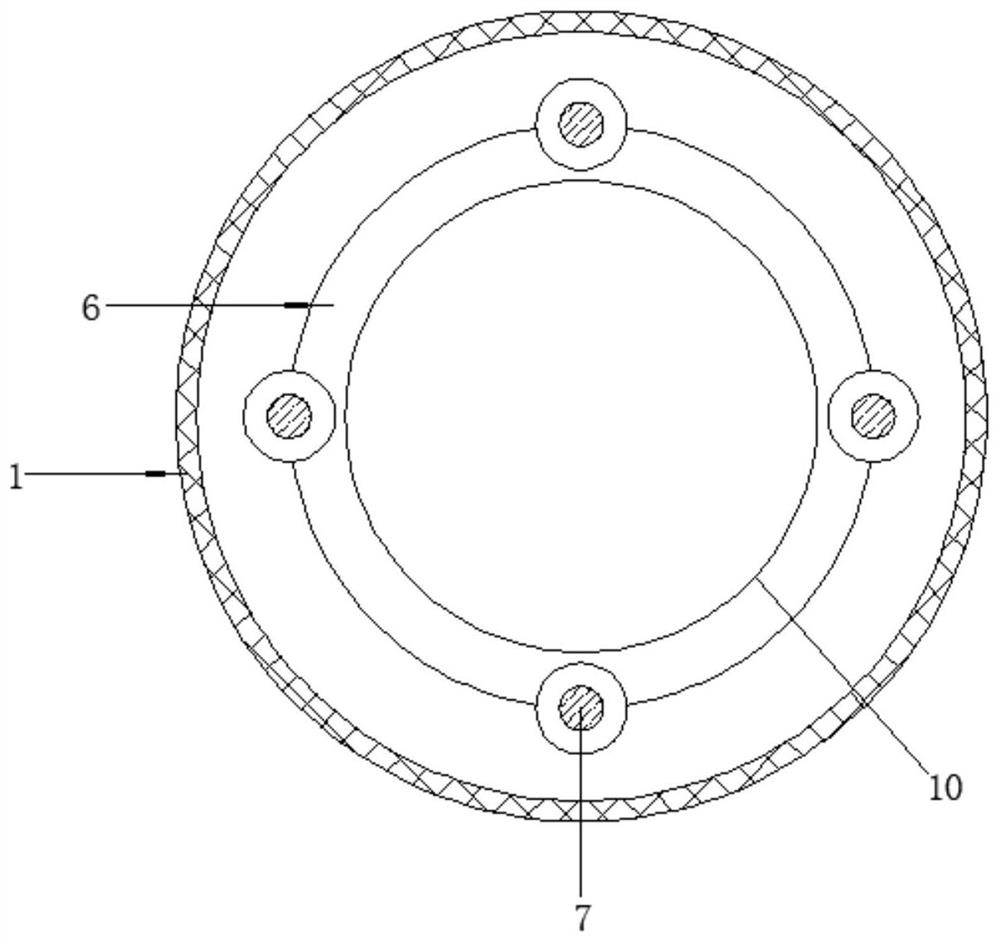

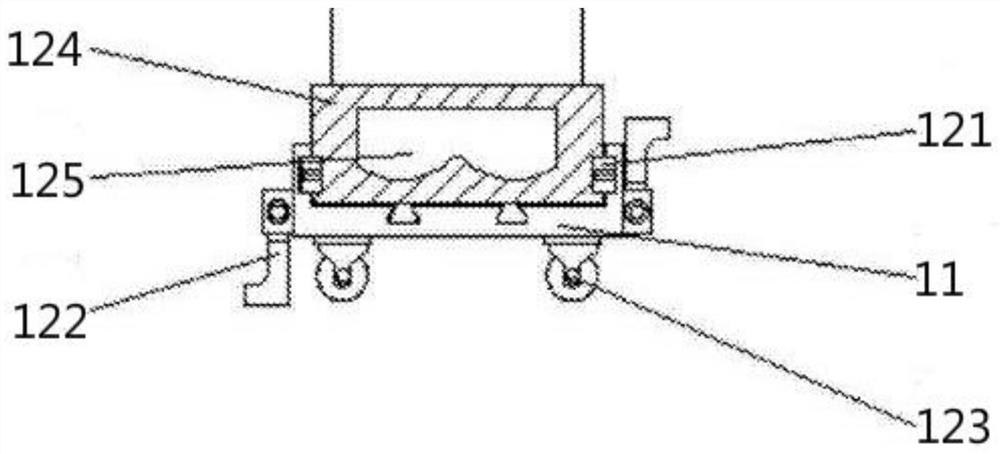

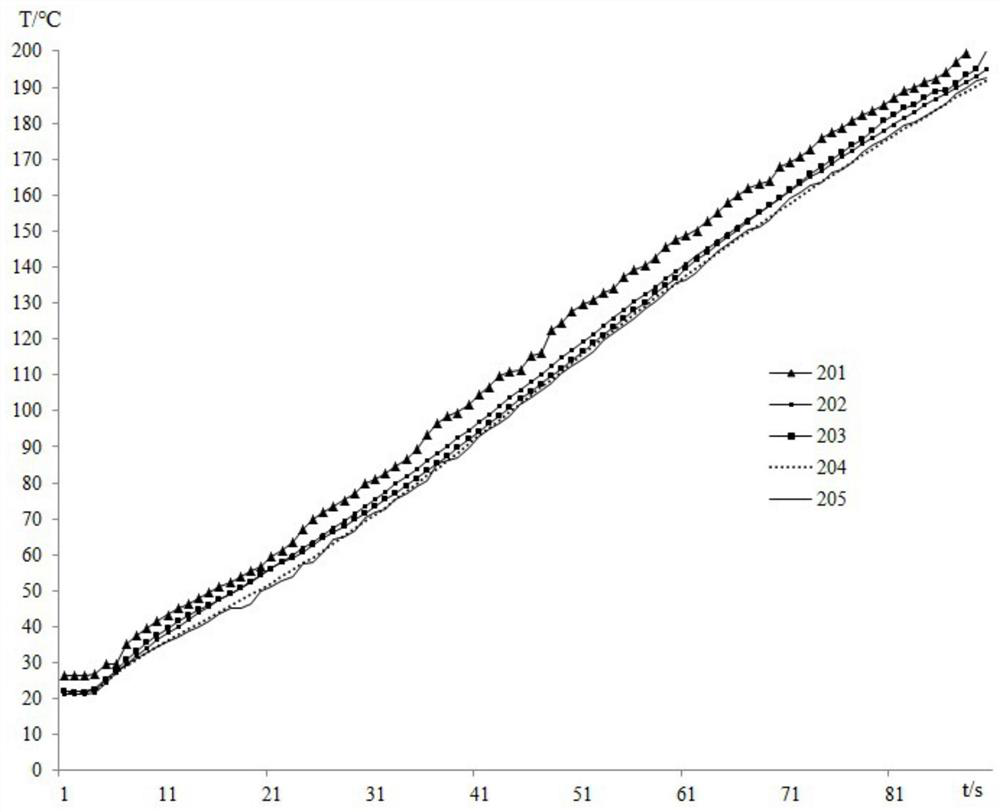

A kind of multiple intelligent protection heating table and its safety control method

ActiveCN105708137BLarge heat radiation areaIncrease temperatureTablesFeetControl systemFlame detection

The invention provides a multiple intelligent protection heating table and safety control method thereof, and relates to the field of intelligent homes. The multiple intelligent protection heating table comprises a fireproof systemarranged on a table top body and a foot rest and a safety control system. The safety control method comprises the following steps: detecting whether a working state of a heat source of the heating table is in abnormal or whether a flame detection signal for indicating the naked flame existing in the heat source is received; when detecting that the heat source is in the abnormal working state, switching off power supply of the heat source, and setting the heat source in an instruction of a non-working state; when the heat source is in the normal working state, setting the heat source in the non-working state while receiving the flame detection signal, refusing to carry out the heating instruction, and executing a firefighting instruction through the starting of a fire extinguishing system. The heating table provided by the invention is good in heat effectand high in security performance, and can realize automatic extinguishing remediation; and the table is simple in structure, low in cost and suitable for public population.

Owner:HUNAN JIAJIAWANG ELECTRIC APPLIANCE TECH

Microwave heating type cracking furnace

InactiveCN101633847BEvenly heatedLarge heat radiation areaBiofuelsSpecial form destructive distillationMicrowavePositive pressure

The invention relates to a microwave heating type cracking furnace for saving fuel resources in a production process. The invention adopts the technical scheme that the microwave heating type cracking furnace comprises a closed heating furnace body and a matched heating, pressure-maintaining and pyrolysis atmosphere maintaining mechanism and adopts a structure integrating pyrolysis, carbonizationand activation. The structure comprises the furnace body and a sliding sealed cover plate which is arranged at the furnace top; the pyrolysis furnace body comprises a pyrolysis furnace chamber which uses a microwave heat source and an activation chamber arranged below the pyrolysis furnace chamber; wherein the pyrolysis furnace chamber is in a positive-pressure, nitrogen-atmosphere and movably sealing-type structure; the sliding sealed cover plate at the top of the pyrolysis furnace chamber is provided with a reverse V-shaped groove rail made of sealing material and a sealing-type friction pair; the reverse V-shaped groove rail is made of embedded sealing material; and the sealing-type friction pair slides with the matched reverse V-shaped groove rail arranged at the upper end of the pyrolysis furnace body. The structure comprises a shell-type stand, and a space in the furnace body is separated into the pyrolysis furnace chamber and the activation chamber by the match of a sealing separator II and the elastic sealing material arranged on a shell in match with a movable sealing matching part. The invention integrally realizes four-in-one operation and has simple structure and strong reliability.

Owner:深圳市兖能环保科技有限公司

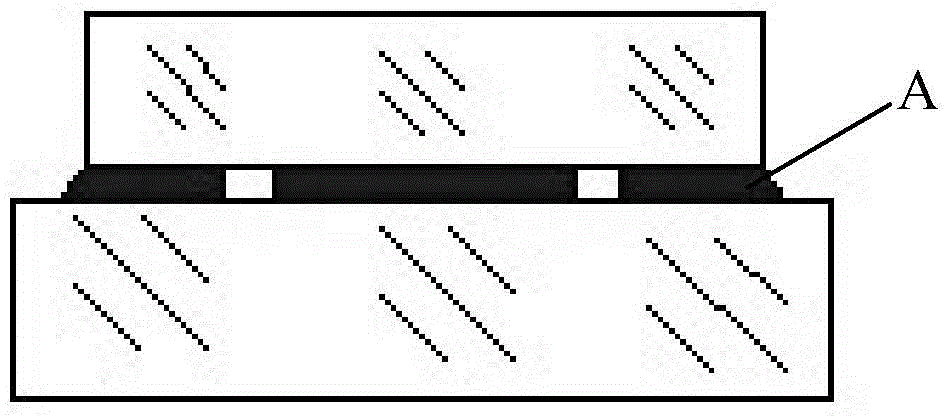

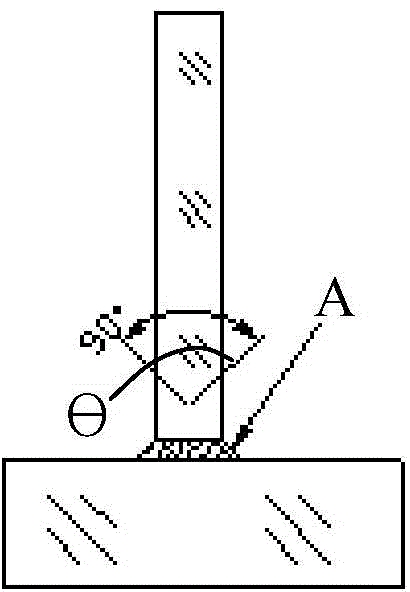

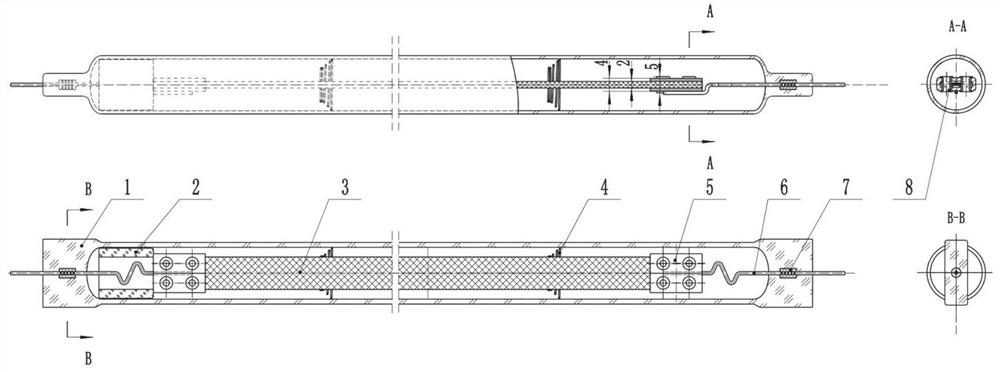

High-power carbon-ceramic composite electric heating tube and processing technology thereof

ActiveCN112654106ALarge heat radiation areaAvoid sparkingHeater elementsHeating element shapesFiberCeramic composite

The invention provides a high-power carbon-ceramic composite electric heating tube. The high-power carbon-ceramic composite electric heating tube comprises an electric heating body, a metal electrode plate, a metal rod electrode and a metal rod electrode sealing sleeve, wherein the electric heating body is composed of a carbon-ceramic composite material blank and a carbon fiber woven electric heating layer wrapping the blank, the electric heating body is of a strip-shaped symmetrical structure, and each end of the electric heating body is sequentially connected with a metal electrode plate and a metal rod electrode; the electric heating body is located in a cavity formed by the outer shell, the metal rod electrode penetrates through one end of the shell, and the portion, making contact with the shell, of the metal rod electrode penetrates through the metal rod electrode sealing sleeve; and the end, connected with the metal electrode plate, of the metal rod electrode is of a Z-shaped arc-shaped bent structure, so that expansion deformation and breakage caused by heating of the electric heating body can be avoided under the condition that large current passes through the Z-shaped arc-shaped bent structure.

Owner:SHANDONG UNIV

Multiple intelligent protection heating table and safety control method thereof

The invention provides a multiple intelligent protection heating table and safety control method thereof, and relates to the field of intelligent homes. The multiple intelligent protection heating table comprises a fireproof systemarranged on a table top body and a foot rest and a safety control system. The safety control method comprises the following steps: detecting whether a working state of a heat source of the heating table is in abnormal or whether a flame detection signal for indicating the naked flame existing in the heat source is received; when detecting that the heat source is in the abnormal working state, switching off power supply of the heat source, and setting the heat source in an instruction of a non-working state; when the heat source is in the normal working state, setting the heat source in the non-working state while receiving the flame detection signal, refusing to carry out the heating instruction, and executing a firefighting instruction through the starting of a fire extinguishing system. The heating table provided by the invention is good in heat effectand high in security performance, and can realize automatic extinguishing remediation; and the table is simple in structure, low in cost and suitable for public population.

Owner:HUNAN JIAJIAWANG ELECTRIC APPLIANCE TECH

Heat treatment furnace for processing high-strength aluminum-magnesium alloy and processing technology of heat treatment furnace

InactiveCN112853070AHeating evenlySimple structural designFurnace typesHeat treatment process controlElectric machineEngineering

The invention discloses a heat treatment furnace for processing high-strength aluminum-magnesium alloy. The heat treatment furnace comprises a shell, the shell is arranged at the upper end of a base through supporting legs, a furnace cover is arranged at the top end of the shell, a feeding groove is formed in the inner surface of the top end of the shell, a supporting frame is arranged on the inner wall of the shell and supports a material frame, a temperature sensor is arranged at the corner of the inner wall of the shell, a controller is arranged on the outer wall of the shell, a motor is installed on the upper surface of the base, a rotating shaft is arranged at the upper end of the motor, a bearing is arranged at the upper end of the motor, the bearing sleeves the outer wall of the rotating shaft, the top end of the rotating shaft extends into the shell, a rotating table is installed at the top end of the rotating shaft, a set of heating devices are installed on the upper surface of the rotating table, and the controller is electrically connected with the motor and the temperature sensor. According to the heat treatment furnace for machining the high-strength aluminum magnesium alloy, the temperature in the furnace can be automatically controlled to be within a proper range all the time and cannot be too high or too low; and the material frame is uniformly heated, the heating efficiency is high, and the material frame is uniformly heated.

Owner:江苏轩辕特种材料科技有限公司

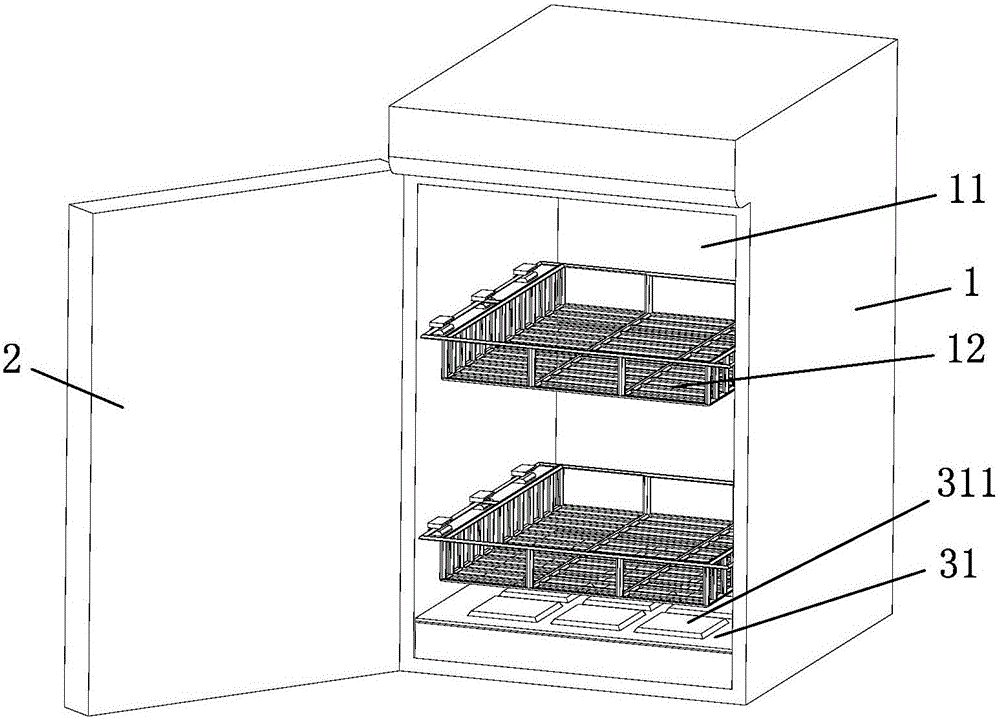

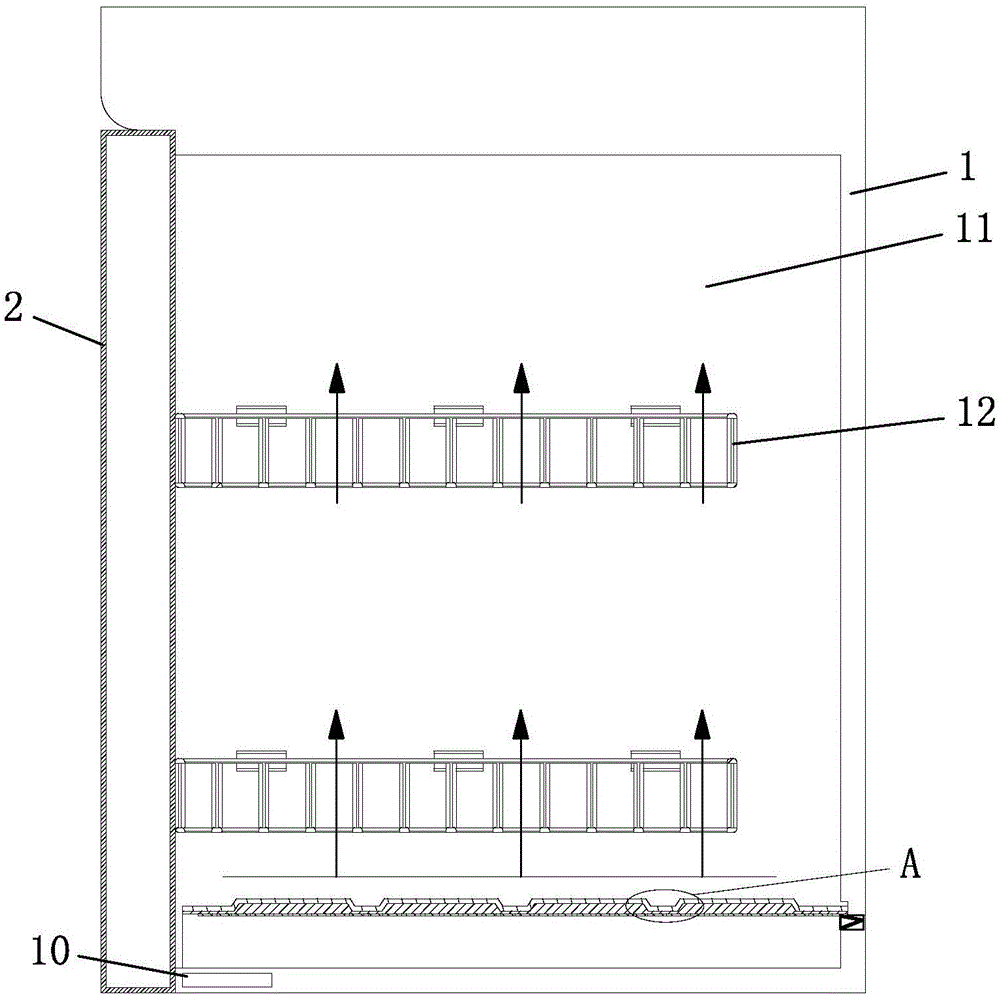

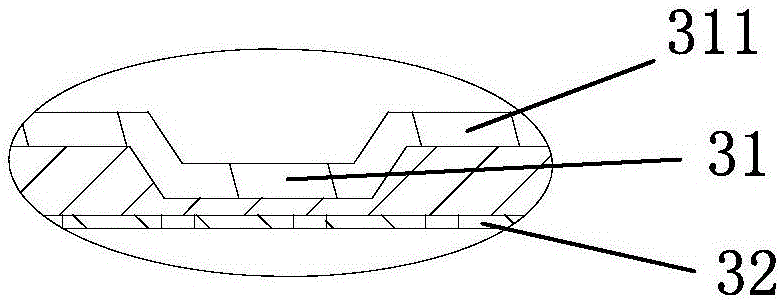

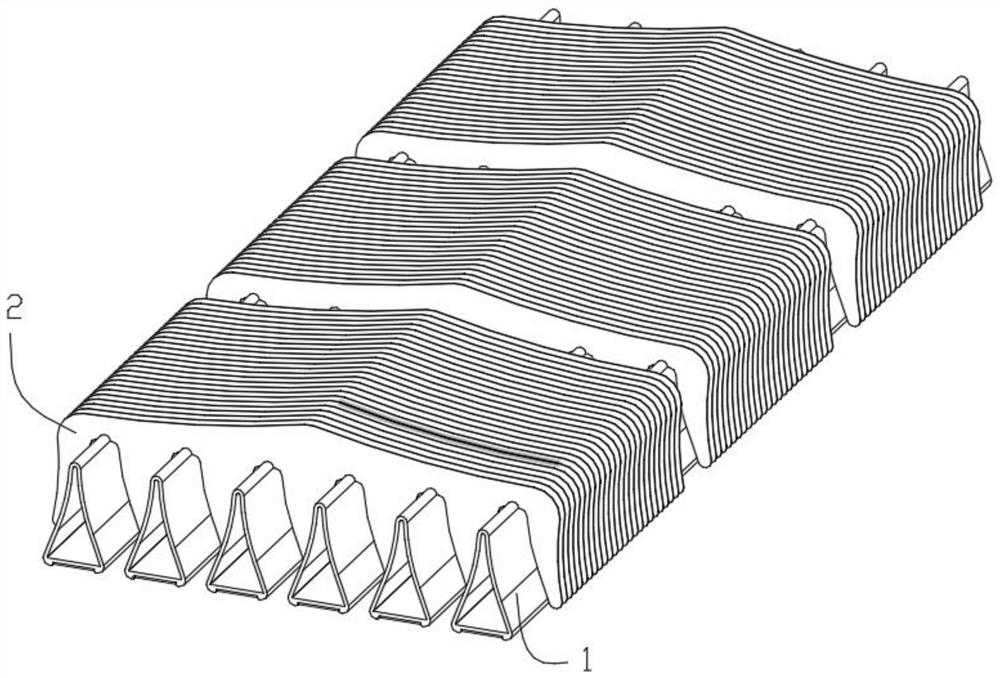

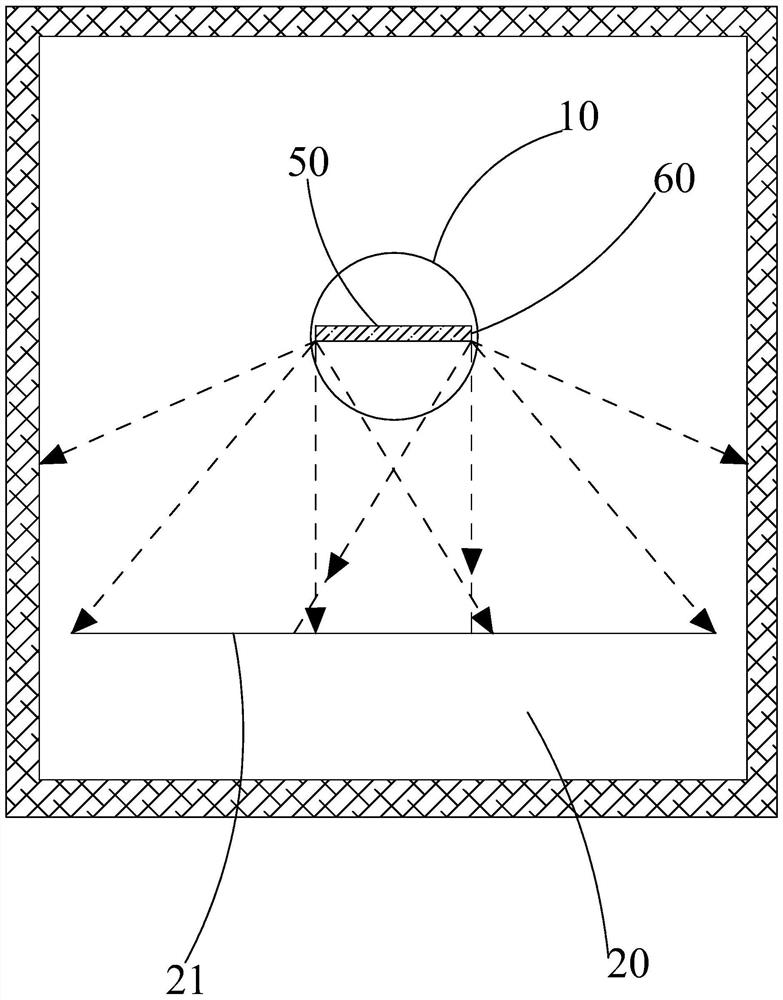

Stereo heating disinfection cabinet based on thick film heating

ActiveCN106798936AImprove energy efficiencyEasy to pasteurizeKitchenware cleanersSustainable buildingsInterior spaceHeat conducting

The invention discloses a stereo heating disinfection cabinet based on thick film heating. The stereo heating disinfection cabinet comprises a cabinet body with a disinfection chamber, and a cabinet door in opening and closing connection with the cabinet body, and is characterized in that a thick film heating plate is arranged at the bottom of the disinfection chamber; the thick film heating plate comprises a main heat-conducting substrate and a main thick film heating circuit printed on the bottom surface of the main heat-conducting substrate. The thick film heating plate of the stereo heating disinfection cabinet can perform heating in the form of planar heat dissipation and is large in heat radiation area and high in heat radiation diffusion speed; the thick film heating plate can perform stereo heating on the interior space of the cabinet body closed by the corresponding cabinet door on a large area from the bottom to the top, and is high in heating speed and high in efficiency; the disinfection cabinet is good in high-temperature disinfecting effect and drying effect and high in energy efficiency.

Owner:GUANDDONG JIBAO ELECTRICAL APPLIANCE TECH CO LTD

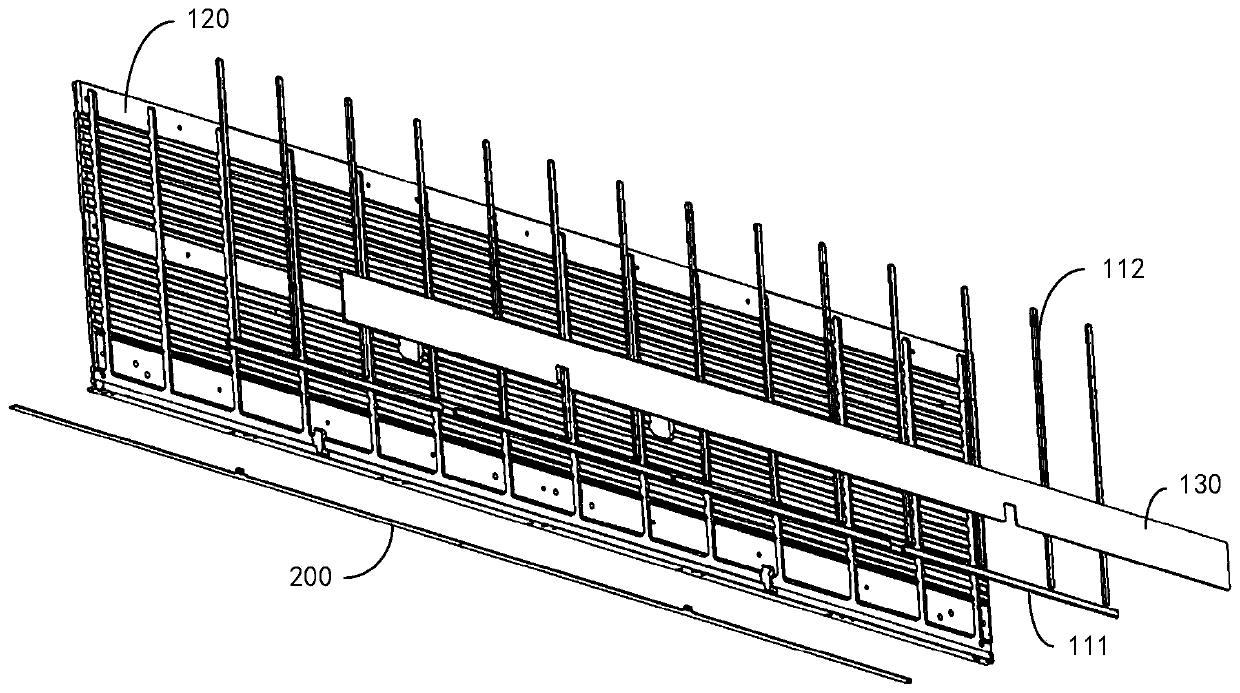

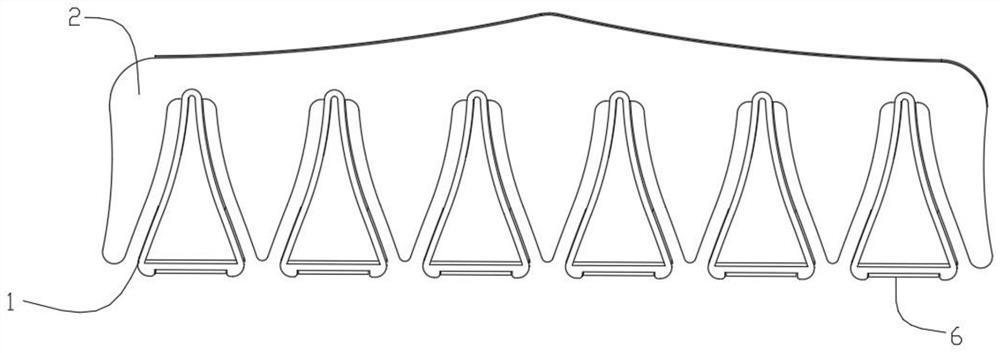

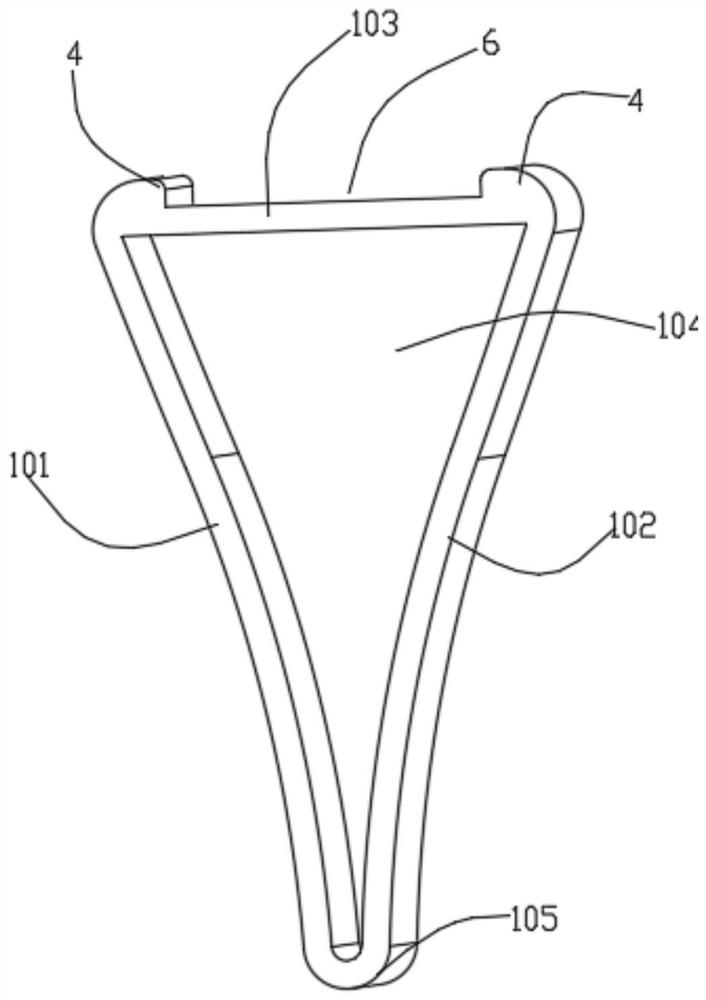

High-efficiency and high-power radiator for LED lamp

PendingCN113803699AEffective protectionLarge heat radiation areaLighting heating/cooling arrangementsSemiconductor devices for light sourcesEngineeringHeat sink

The invention provides a high-efficiency and high-power radiator for an LED lamp. The radiator comprises a sectional material main body, wherein a plurality of groups of radiating fins are installed on the sectional material main body; the sectional material main body is formed by a first sectional material surface, a second sectional material surface and a third sectional material surface which are connected in sequence; the first sectional material surface, the second sectional material surface and the third sectional material surface are sequentially connected to form a hollow cavity structure; the first sectional material surface and the second sectional material surface are of curved surface structures which are sunken towards the cavity structure; a curved surface body structure is arranged at the joint of the first sectional material surface and the second sectional material surface; clamping positions are arranged on the radiating fins correspondingly; and the radiating fins are clamped on the first sectional material surface and the second sectional material surface of the sectional material main body through the clamping positions. The high-efficiency and high-power radiator for the LED lamp has the advantages that the radiating efficiency is high, the LED lamp can be effectively protected, and the high-efficiency and high-power radiator for the LED lamp has great economic value and use value.

Owner:HUIZHOU LIGHT ENGINE LTD

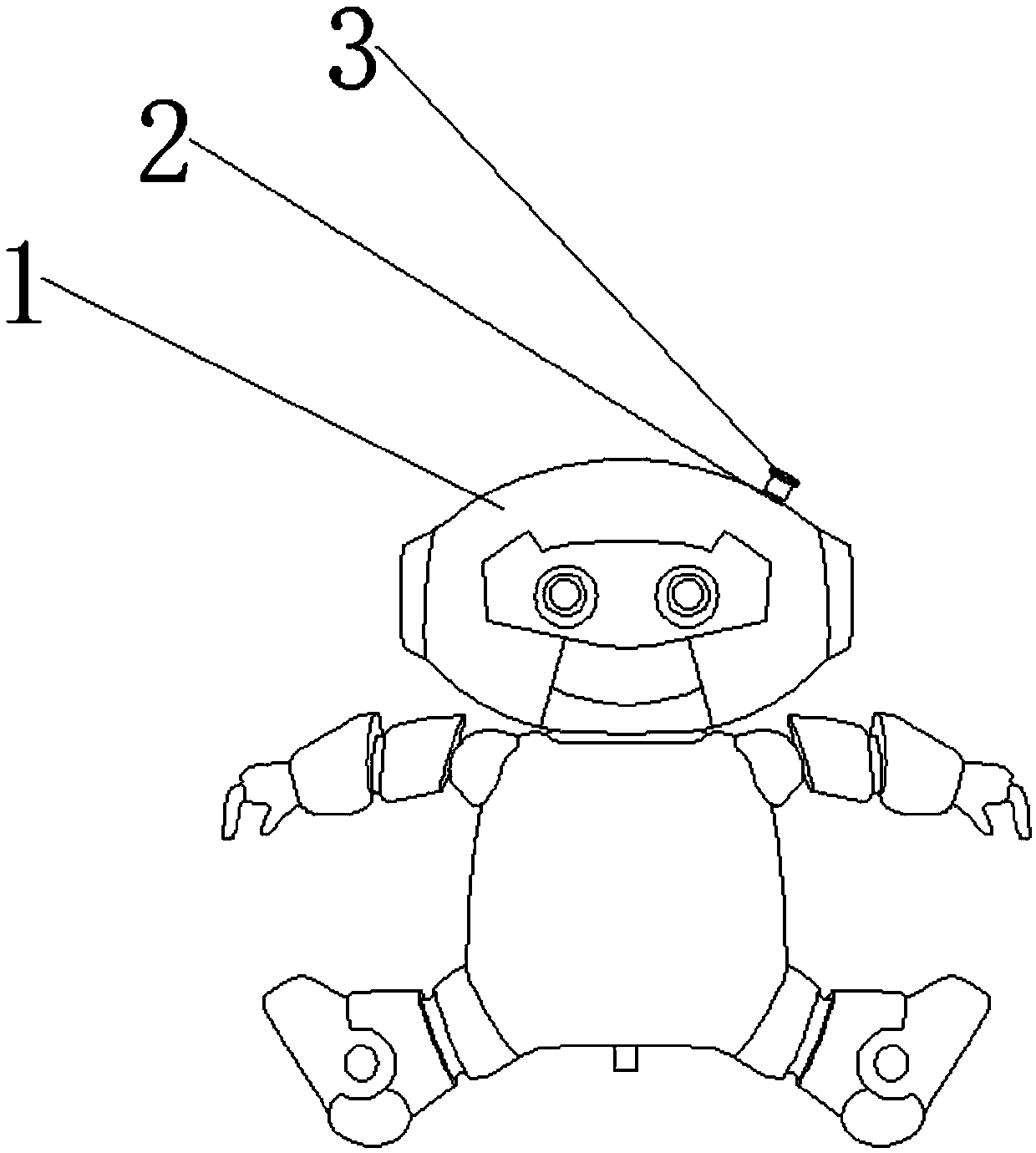

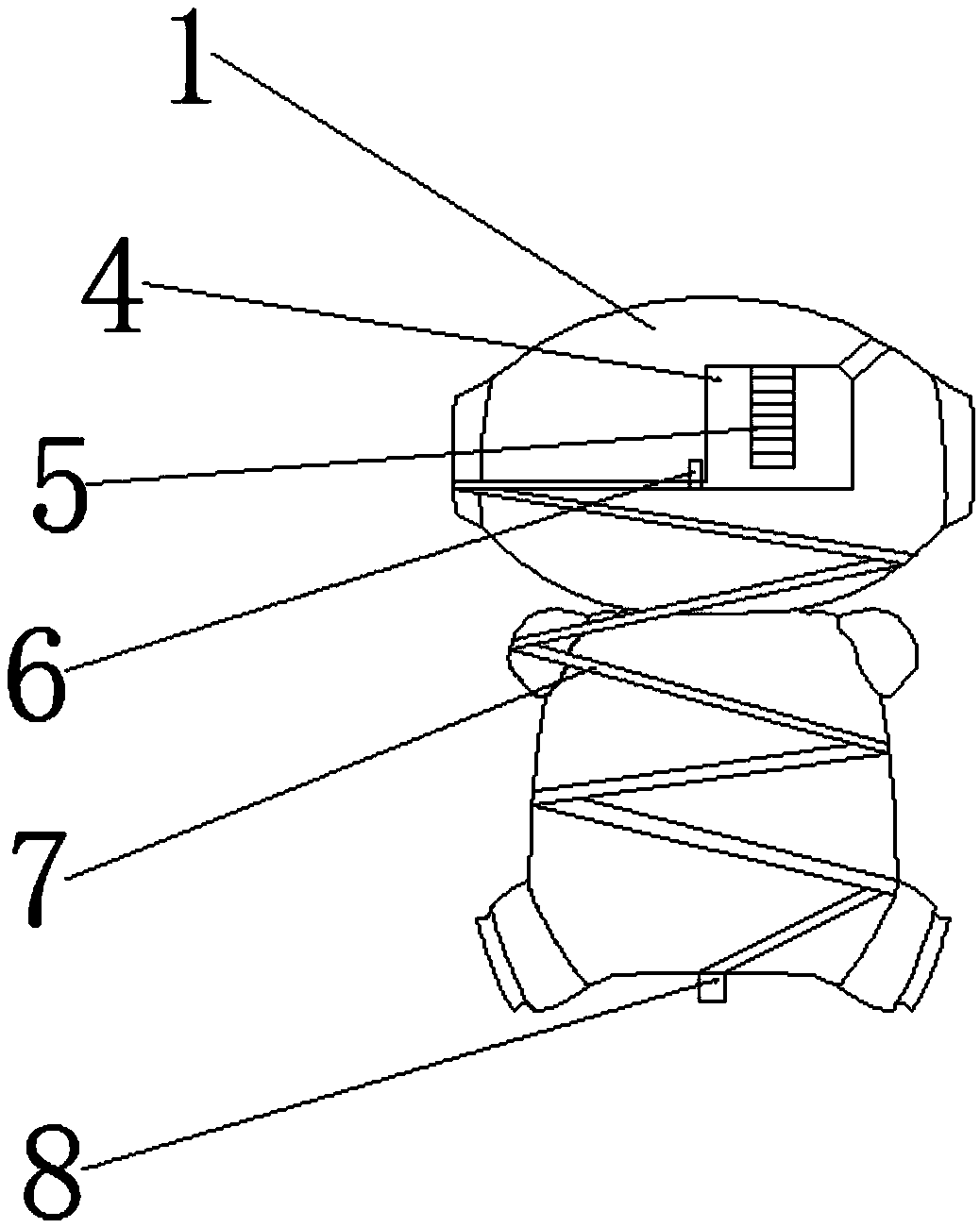

Robot moisture-proof device

InactiveCN108673564ATo achieve the purpose of moisture-proofLarge heat radiation areaManipulatorHeat conductingEngineering

The invention discloses a robot moisture-proof device. The robot moisture-proof device comprises a robot and a heating water tank; a water inlet is formed in one side of the top of the robot and provided with a rubber plug; the rubber plug and the water inlet are movably connected; the heating water tank is arranged on the lower portion of the water inlet and inside the robot; the heating water tank is fixedly connected with the robot; an electric heating wire is arranged inside the heating water tank; tap water is located in the heating water tank; and by setting the temperature of tap waterneeding heating and pressing a heating power key, the electric heating wire heats tap water, a water stop valve is opened, tap water flows into a strip-shaped heat conducting pipe from the heating water tank, and as the strip-shaped heat conducting pipe is wound inside the robot, the thermal radiation area of tap water is greatly increased, the heated tap water evaporates steam inside the robot through thermal radiation, and the purpose of preventing moisture for the robot is achieved.

Owner:芜湖易迅生产力促进中心有限责任公司

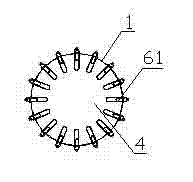

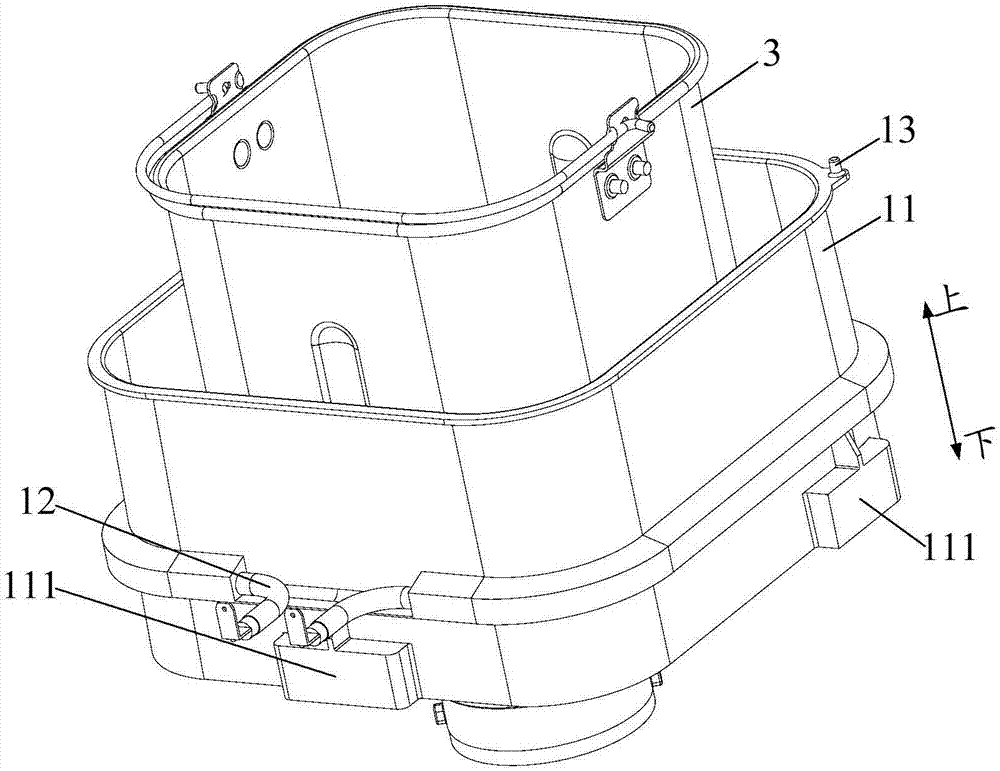

Smokeless barbecuing device

PendingCN107773054ALarge heat radiation areaGood energy saving effectRoasters/grillsWater bathsEnvironmental effect

The invention relates to a smokeless barbecuing device which comprises a heat source furnace. A water tank surrounds the periphery of the heat source furnace, the water tank can hold water, a hangingwall is mounted on the periphery of the water tank, and the hanging wall permits kebabs to be hung between the hanging wall and the heat source furnace. The smokeless barbecuing device comprises the water tank and the heat source furnace. The kebabs can surround the heat source furnace. The smokeless barbecuing device is large in heat radiation area and good in energy-saving effect effectively. Oil water drops into the water tank without smoke, so that the smokeless barbecuing device is good in environment-friendly effect.

Owner:肖水顺

Smokeless grilling table

PendingCN107773055ALarge heat radiation areaGood energy saving effectRoasters/grillsWater bathsEnvironmental effect

The invention relates to a smokeless grilling table. The smokeless grilling table comprises a table and a smokeless grilling device embedded into the table, wherein the smokeless grilling device comprises a heat source furnace; a water tank is arranged around the periphery of the heat source furnace; water can be filled into the water tank; a hanging wall is mounted at the periphery of the water tank; and the hanging wall is used for allowing skewers to be hung between the hanging wall and the heat source furnace. The smokeless grilling table provided by the invention contains the water tank and the heat source furnace; the skewers can be hung around the heat source furnace, the effective heat radiation area is large and the energy-saving effect is good; and when oily water drips into thewater tank, lampblack is not formed, so that the environment-friendly effect is good.

Owner:肖水顺

Cooking utensil with high cooking efficiency

PendingCN113156838AUniform radiant heatingImprove cooking resultsProgramme controlComputer controlPhysicsDirect radiation

The invention relates to a cooking utensil with high cooking efficiency, the cooking utensil comprises a cooking cavity and a heating pipe installed in the cooking cavity, the heating pipe comprises a container, a sheet-shaped heating body suspended in the container and a power supply part penetrating out of the two ends of the container, the two ends of the heating body are connected with the power supply part, the heating body comprises a plane part and a linear side part, and the side part faces a food material placing area in the cooking cavity. According to the technical scheme provided by the invention, the risk that food is locally burnt due to direct radiation of the plane part can be avoided, so that relatively uniform radiation heating is realized, and the cooking effect is improved.

Owner:HONGYANG HOME APPLIANCES

A heat dissipation structure of a high-power chip of an automobile audio entertainment system host

PendingCN109148395AExtend working lifeExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesEngineeringSilica gel

The invention relates to a high-power chip heat dissipation structure of an automobile audio entertainment system host, Including top shell, extruded aluminum fin, heat sink cover plate, heat dissipate silica gel pad, a PCB board and a middle frame for mounting a high-power chip, Top shell, extruded aluminum fin, A PCB board is fixedly installed on the middle frame from top to bottom in turn, Thetop shell covers the top of the extruded aluminum fin, the cover plate covers the front and back sides of the extruded aluminum fin, the heat dissipation silica gel pad is arranged between the extruded aluminum fin and the high-power chip, the heat dissipation silica gel pad is pasted on the high-power chip, and the heat dissipation silica gel pad is extruded and fixed by the bottom of the extruded aluminum fin. The aluminum-extruded fin comprises a stepped mounting frame and a plurality of heat dissipation trapezoidal teeth, which are manufactured by an aluminum-extruding process, wherein thestepped mounting frame and the heat dissipation trapezoidal teeth are formed by an aluminum extrusion process. The whole structure design of the heat dissipation structure is ingenious, and the heatdissipation area is greatly increased through the special structure of the aluminum-extruded heat dissipation fin combined with the heat dissipation fin cover plate and the heat dissipation silica gelpad, so that the rapid heat dissipation of the high-power chip can be realized.

Owner:YANFENG VISTEON ELECTRONICS TECH NANJING

A multi-layer heat treatment hanger furnace

InactiveCN106809723AIncrease discharge densitySimple structureLoad-engaging elementsEngineeringThermal radiation

A multilayer heat treatment hanging bracket furnace is made of heat-resisting steel. The multilayer heat treatment hanging bracket furnace is characterized by comprising a heating device, a connecting rod, a furnace body, a material plate, a cover, containing holes, a sliding rod and a pushing plate; the upper end and the lower end of a hanging bracket are connected with a lifting hook and a base plate in a welded manner, multiple layers of supports are welded to the hanging bracket, and therefore multilayer separating is achieved; a separating frame can be stably placed on the support and can also be stably taken down from the supports; the lifting hook is of a ring-shaped structure; the hanging bracket is of a square frame structure; and a plurality of containing holes are formed in a material plate, and the shapes of the containing holes are cross section shapes of a drill thread. The multilayer heat treatment hanging bracket furnace ash the beneficial effects that the structure is simple, the practicability is high, the production cost is reduced, the discharging density of the material plate is improved, the heat radiation area is accordingly increased, and temperature rise is accelerated.

Owner:王百龙

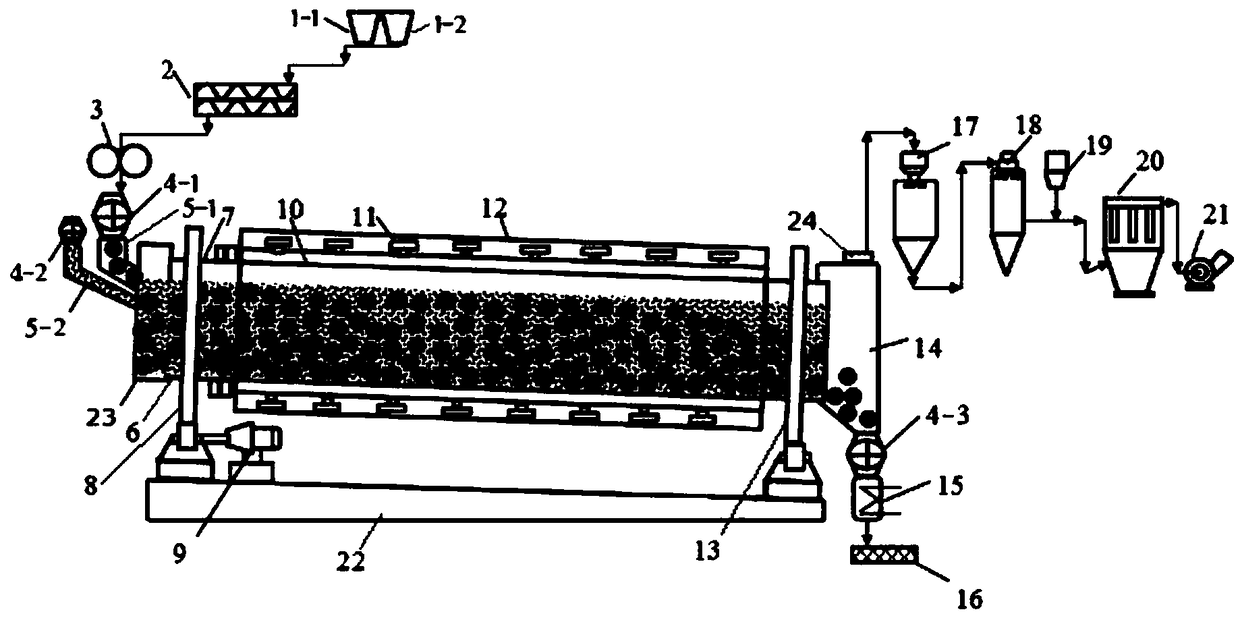

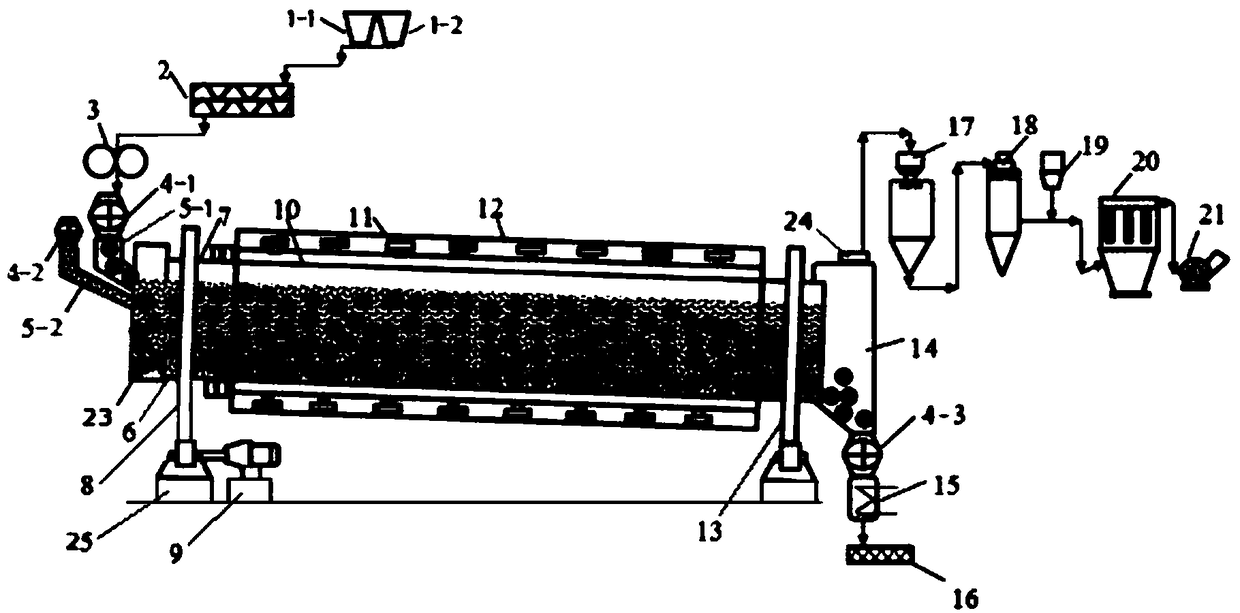

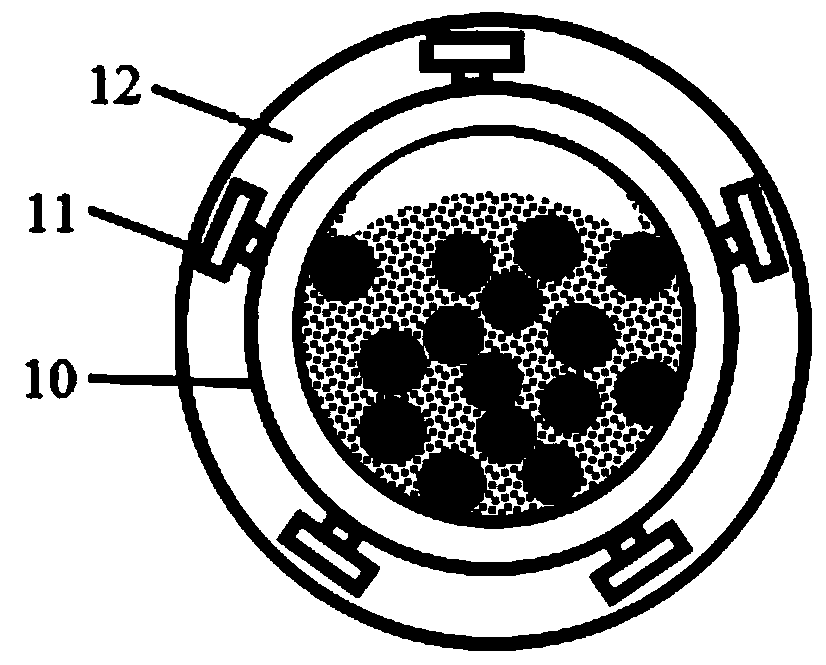

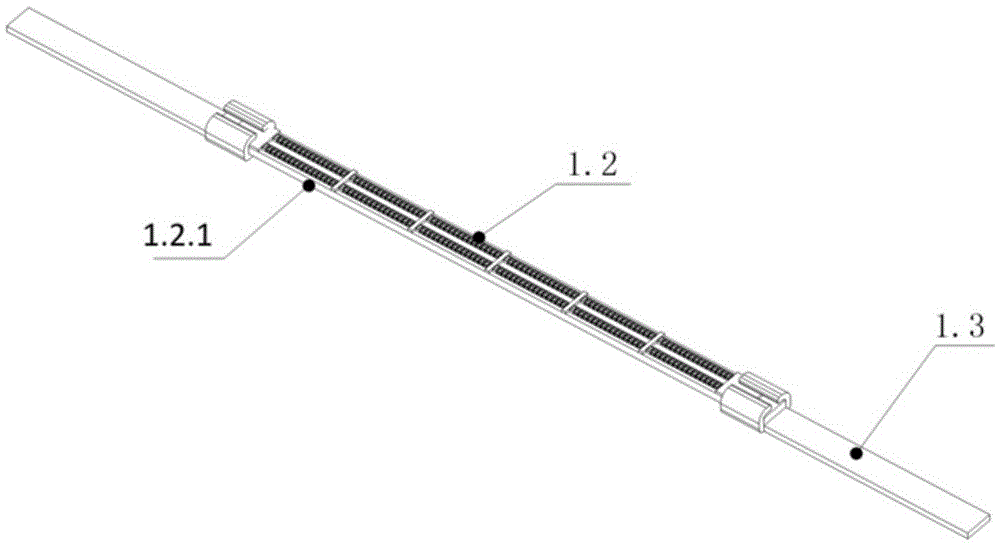

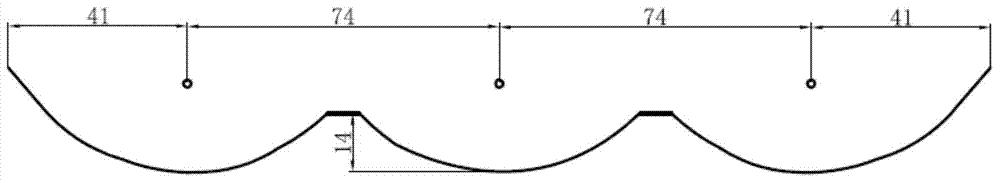

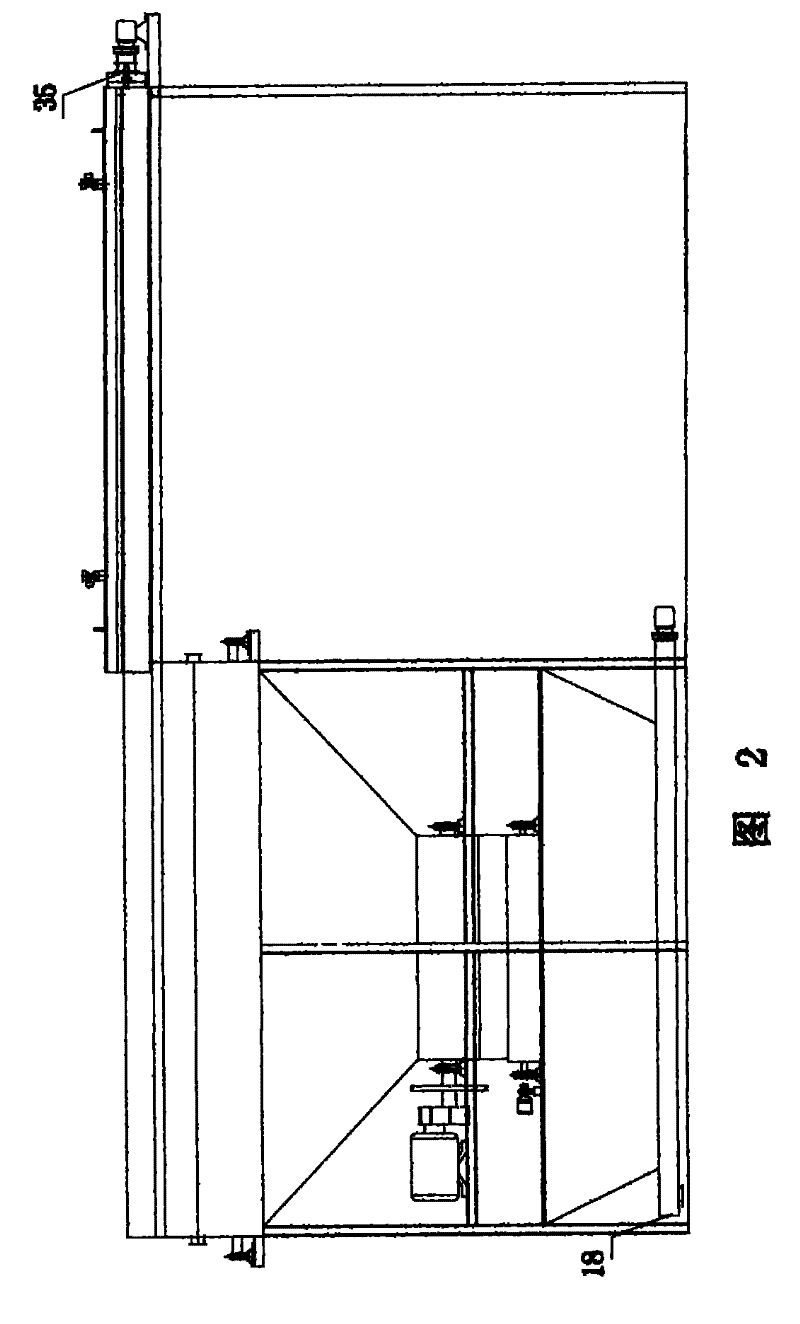

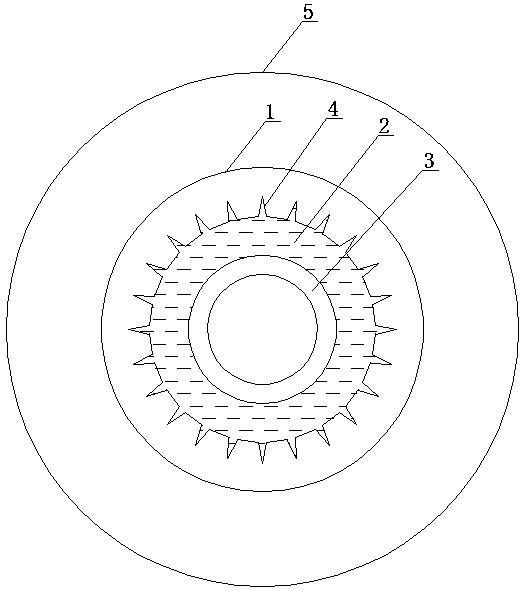

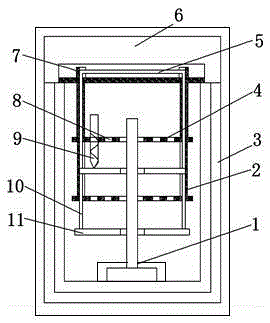

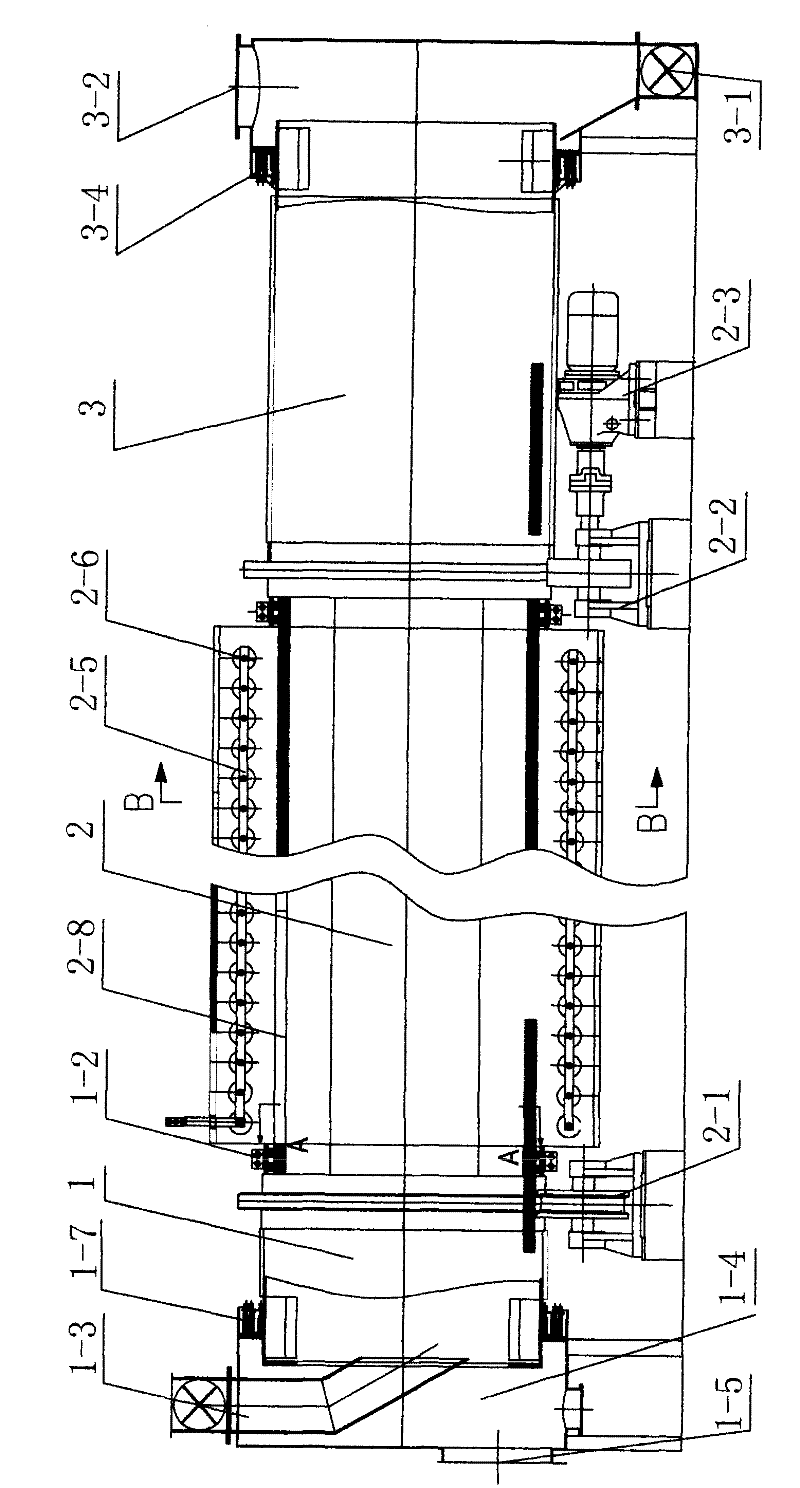

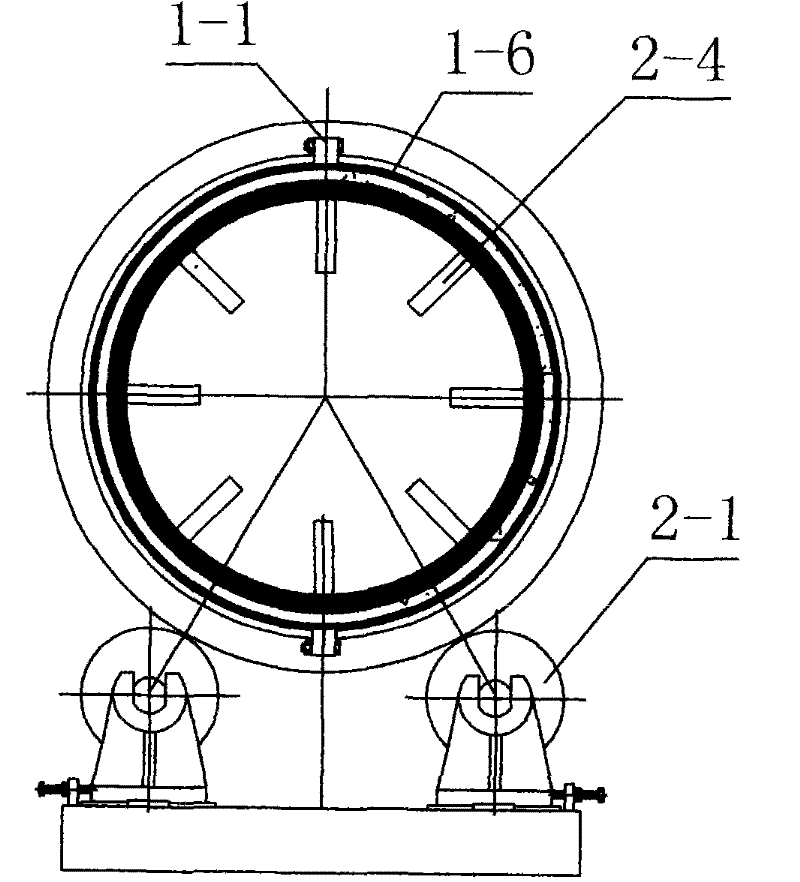

Rotary type microwave oven, system and method for preparing activated carbon

InactiveCN101863468BEvenly heatedLarge heat radiation areaCarbon compoundsActivated carbonMicrowave oven

The method relates to a rotary type microwave oven, a system and a method for preparing activated carbon, which solve the problem that the conventional technology source cannot be fully used. The rotary type microwave oven adopts the technical scheme that the rotary type microwave oven is provided with a sealed shell cylinder structure ring and a matched microwave heater, wherein a sealed shell cylinder is a horizontal rotary type sealed shell cylinder; the inner space of a sealed shell is provided with a material distributing chamber, a processing chamber and a cooling chamber which are connected in turn; a front end of the material distributing chamber is provided with a feeding hole; the material distributing chamber and the processing chamber, and the processing chamber and the cooling chamber are in positioned connection respectively; two ends of the processing chamber are connected with the material distributing chamber and the cooling chamber respectively and are arranged on a friction driving wheel and a friction driven wheel; the friction driving wheel is driven by a motor; and the tail end of the cooling chamber is provided with a discharging hole and a smoke outlet. Therotary type microwave oven is used in the system and the method for preparing the activated carbon. The rotary type microwave oven has the advantages of uniform heating of materials due to microwave heating, large heat radiation area, quick temperature rise and capability of realizing cyclic utilization of heat energy and water vapor.

Owner:深圳市兖能环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com