Heat treatment furnace for processing high-strength aluminum-magnesium alloy and processing technology of heat treatment furnace

A technology of aluminum-magnesium alloy and heat treatment furnace, which is applied in heat treatment furnace, heat treatment equipment, heat treatment process control, etc., can solve the problems of uneven and consistent temperature, and achieve the effect of uniform temperature, convenient operation and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

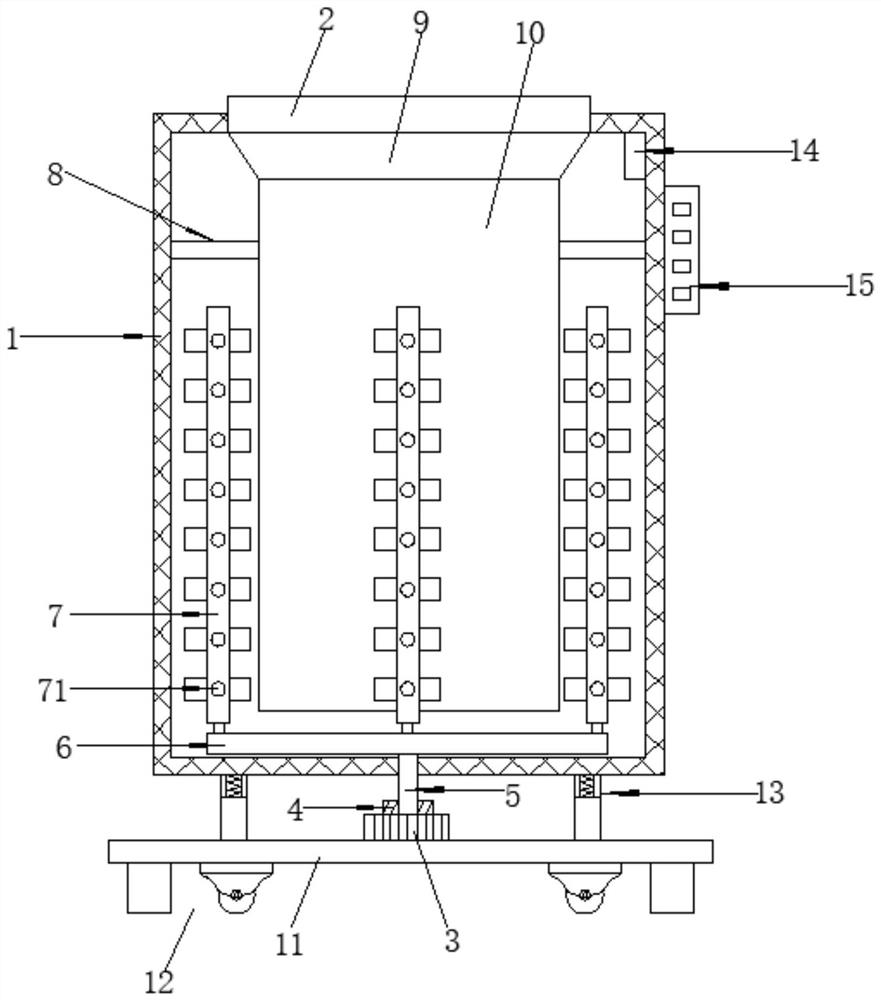

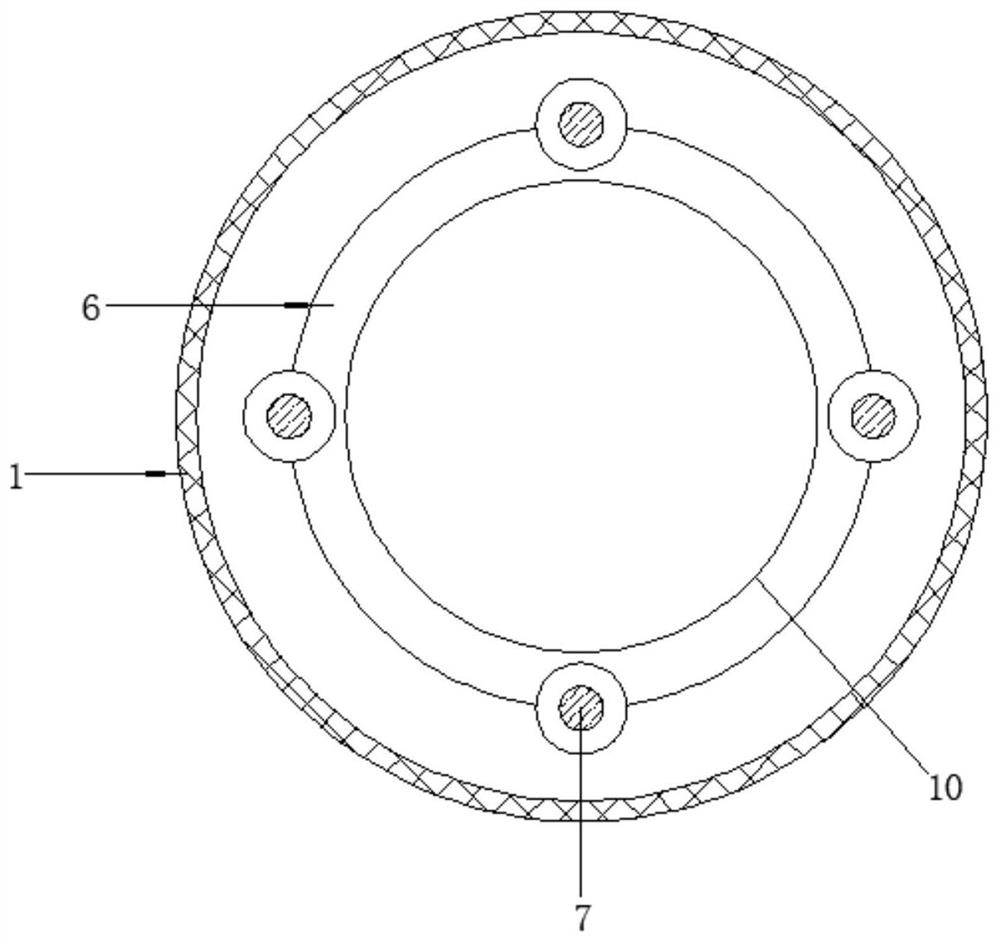

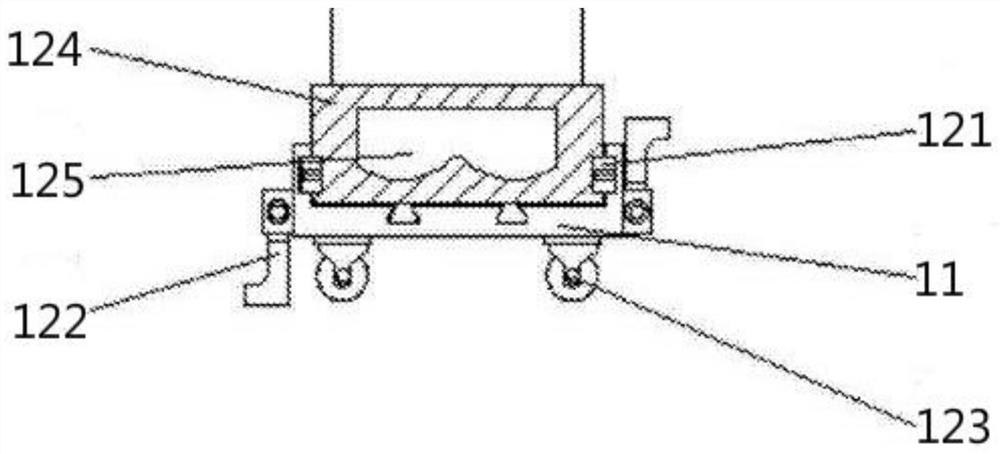

[0023] Such as Figure 1-2 The shown heat treatment furnace for processing high-strength aluminum-magnesium alloys includes a casing 1, a furnace cover 2, a motor 3, a rotary table 6, a heating device 7, a material frame 10, a base 11, a temperature sensor 14 and a controller 15. The casing 1 is set on the upper end of the base 11 through a set of supporting feet 13, the shell 1 is an insulating layer, the top of the shell 1 is provided with a furnace cover 2, the inner surface of the top end of the shell 1 is provided with a feeding groove 9, and the shell 1 The inner wall is provided with a support frame 8, the support frame 8 supports the material frame 10, a temperature sensor 14 is provided at the corner of the inner wall of the housing 1, a controller 15 is provided on the outer wall of the housing 1, and the motor 3 is installed on the base 11 On the surface, the upper end of the motor 3 is provided with a rotating shaft 5, the upper end of the motor 3 is provided with ...

Embodiment 2

[0027] Such as Figure 1-2 The shown heat treatment furnace for processing high-strength aluminum-magnesium alloys includes a casing 1, a furnace cover 2, a motor 3, a rotary table 6, a heating device 7, a material frame 10, a base 11, a temperature sensor 14 and a controller 15. The casing 1 is set on the upper end of the base 11 through a set of supporting feet 13, the shell 1 is an insulating layer, the top of the shell 1 is provided with a furnace cover 2, the inner surface of the top end of the shell 1 is provided with a feeding groove 9, and the shell 1 The inner wall is provided with a support frame 8, the support frame 8 supports the material frame 10, a temperature sensor 14 is provided at the corner of the inner wall of the housing 1, a controller 15 is provided on the outer wall of the housing 1, and the motor 3 is installed on the base 11 On the surface, the upper end of the motor 3 is provided with a rotating shaft 5, the upper end of the motor 3 is provided with ...

Embodiment 3

[0031] Such as Figure 1-2 The shown heat treatment furnace for processing high-strength aluminum-magnesium alloys includes a casing 1, a furnace cover 2, a motor 3, a rotary table 6, a heating device 7, a material frame 10, a base 11, a temperature sensor 14 and a controller 15. The casing 1 is set on the upper end of the base 11 through a set of supporting feet 13, the shell 1 is an insulating layer, the top of the shell 1 is provided with a furnace cover 2, the inner surface of the top end of the shell 1 is provided with a feeding groove 9, and the shell 1 The inner wall is provided with a support frame 8, the support frame 8 supports the material frame 10, a temperature sensor 14 is provided at the corner of the inner wall of the housing 1, a controller 15 is provided on the outer wall of the housing 1, and the motor 3 is installed on the base 11 On the surface, the upper end of the motor 3 is provided with a rotating shaft 5, the upper end of the motor 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com