A multi-layer heat treatment hanger furnace

A hanger and hook technology, which is applied in the field of multi-layer heat treatment hanger furnaces, can solve the problems of difficulty in meeting heat treatment requirements and poor heat resistance, and achieve the effects of simple structure, improved discharge density and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

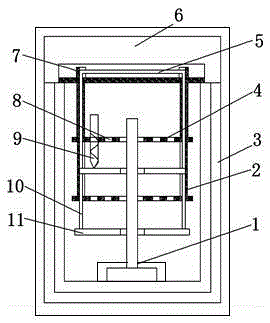

[0009] This embodiment provides a multi-layer heat treatment hanger furnace, which is made of heat-resistant steel, and is characterized in that it includes a heating device, a connecting rod, a furnace body, a material plate, a cover, a placement hole, a slide bar and a pusher plate, The upper end and the lower end of the hanger are respectively welded with the hook and the bottom plate, and the hanger is welded with multiple layers of the bracket to realize multi-layer separation; the spacer can be placed on the bracket smoothly , can also be removed from the bracket smoothly; the hook is a ring structure; the hanger is a square frame structure; the material plate is provided with several placement holes, and the shape of the placement holes is a drill thread cross-sectional shape.

[0010] The invention has the advantages of simple structure, strong practicability, reduced production cost, and increased discharge density of the material board, thereby increasing the heat ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com