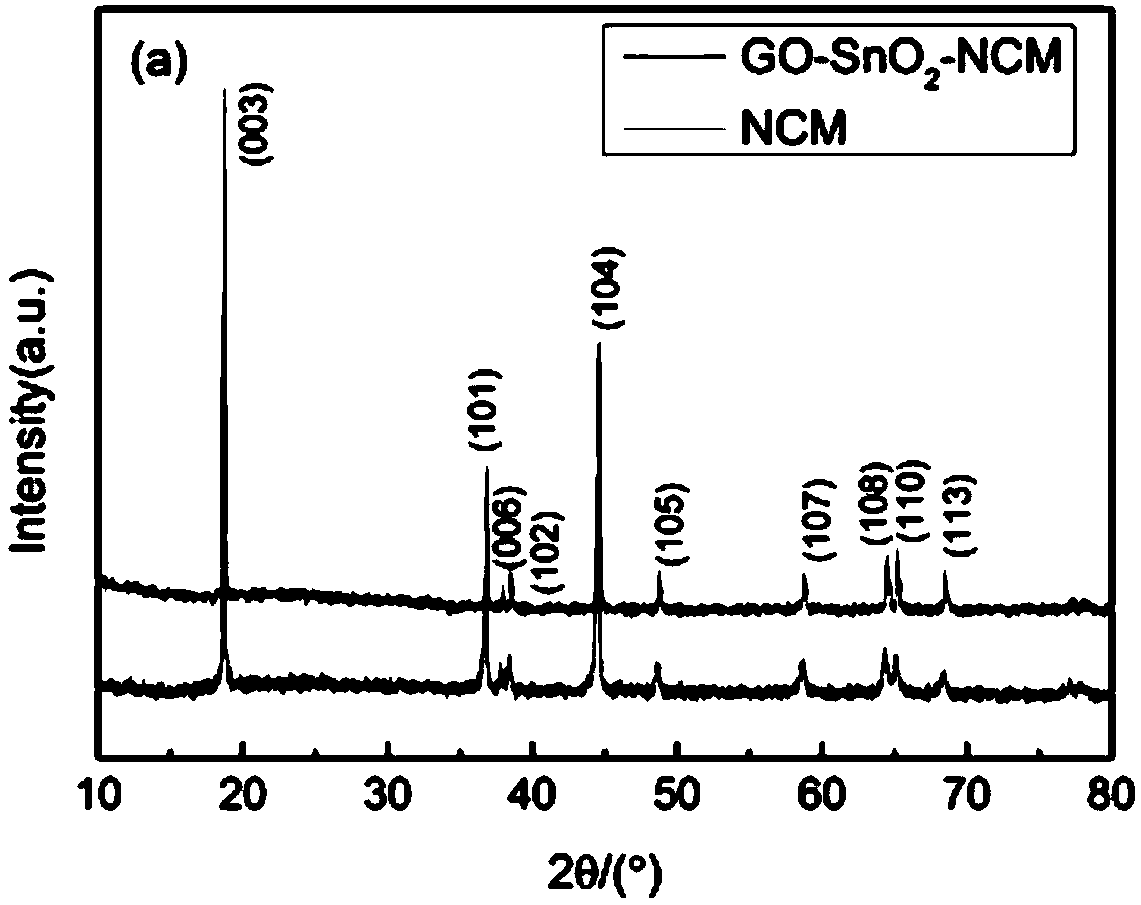

Ternary cathode active material of lithium ion battery, preparation method thereof, cathode material, lithium ion battery and product thereof

A positive electrode active material, lithium-ion battery technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problem of poor battery rate performance and cycle performance, affecting lithium ion intercalation and extraction rates, and uneven particle size of active materials and other issues to achieve high rate performance and cycle performance, excellent capacity and stability, and easy insertion or removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] In a second aspect, a method for preparing the above-mentioned ternary positive electrode active material for a lithium-ion battery is provided, comprising the steps of:

[0086] (a) providing a nickel-cobalt-manganese positive electrode material; (b) coating tin dioxide on the surface of the nickel-cobalt-manganese positive electrode material to obtain a nickel-cobalt-manganese positive electrode material coated with nanoscale tin dioxide on the surface; (c) coating the surface The nickel-cobalt-manganese positive electrode material with nanoscale tin dioxide is embedded in the graphene oxide sheet structure to obtain the ternary positive electrode active material of the lithium ion battery.

[0087] The nickel-cobalt-manganese cathode material can be self-prepared or obtained by other means, and can be purchased nickel-cobalt-manganese cathode material. Then, it is coated with nano-scale tin dioxide, so that the surface of the nickel-cobalt-manganese cathode material ...

Embodiment 1

[0140] A kind of lithium ion battery ternary cathode active material, its LiNi 0.5 co 0.2 mn 0.3 o 2 The coating amount of tin dioxide coated on the surface of the material is 3%, and the surface is coated with tin dioxide LiNi 0.5 co 0.2 mn 0.3 o 2 The material is embedded in the graphene oxide sheet structure, and the coating amount of graphene oxide is 3%.

[0141] The preparation process is as follows:

[0142] MnO 2 Preparation of hollow microspheres: MnCO 3 Put the powder into a corundum porcelain boat, calcinate in a tube furnace, control the heating rate of 10°C / min, raise the temperature from room temperature to 500°C, keep it at 500°C for 6 hours, and cool to room temperature with the furnace to obtain MnO 2 hollow microspheres.

[0143] LiNi 0.5 co 0.2 mn 0.3 o 2 Preparation of materials:

[0144] Weigh 1.07g of lithium acetate, 1.24g of nickel acetate, 0.5g of cobalt acetate, and 0.24g of manganese dioxide, dissolve them in 100ml of absolute ethanol,...

Embodiment 2

[0148] A kind of lithium ion battery ternary cathode active material, its LiNi 0.5 co 0.2 mn 0.3 o 2 The coating amount of tin dioxide coated on the surface of the material is 1%, and the LiNi coated with tin dioxide on the surface 0.5 co 0.2 mn 0.3 o 2 The material is embedded in the graphene oxide sheet structure, and the coating amount of graphene oxide is 1%.

[0149] The preparation process is as follows:

[0150] MnO 2 Preparation of hollow microspheres: MnCO 3 Put the powder into a corundum porcelain boat, calcinate in a tube furnace, control the heating rate of 10°C / min, raise the temperature from room temperature to 450°C, keep it at 450°C for 5 hours, and cool to room temperature with the furnace to obtain MnO 2 hollow microspheres.

[0151] LiNi 0.5 co 0.2 mn 0.3 o 2 Preparation of materials:

[0152]Weigh 1.07g of lithium acetate, 1.24g of nickel acetate, 0.5g of cobalt acetate, and 0.74g of manganese acetate and dissolve them in 100ml of absolute et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com