Decomposition equipment for crushed coal and pulverized coal

A technology for pulverized coal and coal crushing, which is used in energy saving and emission reduction equipment, comprehensive utilization of pulverized coal, and coal crushing fields, can solve problems such as difficulty in accurate control, loss of production and maintenance, safety problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

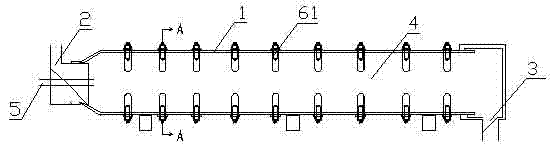

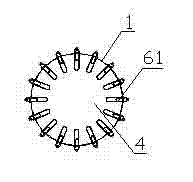

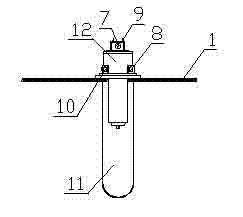

[0025] Such as figure 1 , figure 2 , image 3Shown: a broken coal, pulverized coal decomposition equipment, including a horizontal airtight rotary kiln body 1 with a feed port 2 and a discharge port 3, the kiln wall of the kiln body 1 is provided with a heating mechanism, the The pulverized coal and pulverized coal propulsion decomposition channel 4 formed between the heating mechanism and the kiln body wall, the coal decomposition gas collection pipe 5 communicating with the pulverized coal and pulverized coal promotion and decomposition channel is arranged on the kiln body, and the heating mechanism is a large number of The columnar fuel heating pipe 6, the fuel inlet 7, the air inlet 8, the igniter 9, the burner 12, and the flame gas outlet 10 of the columnar fuel heating pipe 6 are arranged outside the kiln wall, and the radiation connected to the burner 12 The pipe 11 extends into the kiln wall, and the flame gas outlet communicates with the radiant pipe. The fuel in ...

Embodiment 2

[0027] Such as Figure 4 Shown: a broken coal, pulverized coal decomposition equipment, including a horizontal airtight rotary kiln body 1 with a feed port 2 and a discharge port 3, the kiln wall of the kiln body 1 is provided with a heating mechanism, the The pulverized coal and pulverized coal propulsion decomposition channel 4 formed between the heating mechanism and the kiln body wall, the coal decomposition gas collection pipe 5 communicating with the pulverized coal and pulverized coal promotion and decomposition channel is arranged on the kiln body, and the heating mechanism is a large number of U-shaped fuel heating pipe 62, the two ends of the U-shaped fuel heating pipe are arranged outside the kiln wall, one end is provided with fuel inlet, air inlet, igniter and burner, and the other end is provided with flame gas outlet , the radiant tube in the saddle is set inside the kiln wall and communicates with the two ends. The fuel in the fuel inlet and the air in the air...

Embodiment 3

[0029] Such as Figure 5 Shown: a broken coal, pulverized coal decomposition equipment, including a horizontal airtight rotary kiln body 1 with a feed port 2 and a discharge port 3, the kiln wall of the kiln body 1 is provided with a heating mechanism, the The pulverized coal and pulverized coal propulsion and decomposition channel 4 formed between the heating mechanism and the kiln body wall, the coal decomposition gas collection pipe 5 communicating with the pulverized coal and pulverized coal promotion and decomposition channel is arranged on the kiln body, and the heating mechanism is a A group of U-shaped fuel heating pipes 62 surrounding the kiln body. The two ends of the U-shaped fuel heating pipe are arranged outside the kiln wall, and the two ends are respectively close to the two ends of the kiln body. One end is provided with fuel inlet, air Inlet, igniter and burner, flame gas outlet is set at the other end, and the radiant tube at the saddle is set inside the kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com