High-power carbon-ceramic composite electric heating tube and processing technology thereof

A high-power, electric heating tube technology, used in electric heating devices, ohmic resistance heating, ohmic resistance heating components and other directions, can solve the problems of carbon fiber spiral electric heating body damage, burning and bursting end seals, easy to produce burrs, etc., to achieve no impact The effect of current heat radiation intensity, increasing heat radiation area, and avoiding ignition phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

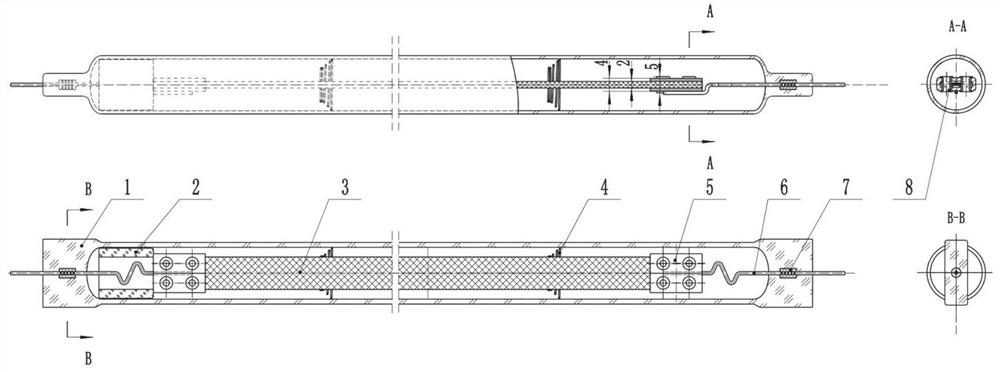

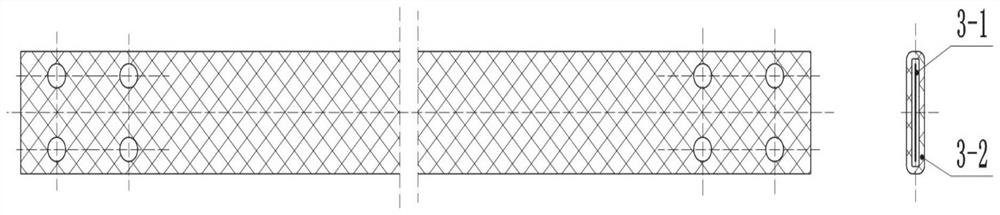

[0058] See attached figure 1 As shown, this embodiment discloses a hybrid high-power carbon-ceramic composite electric heating tube, including: a quartz tube or a ceramic tube outer shell 1, an axial support sleeve 2, an electric heating body 3, a radial support frame 4, and a metal electrode sheet 5. Metal rod electrode 6, metal rod electrode sealing sleeve 7, fixed riveting tube 8.

[0059] A high-power carbon-ceramic composite electric heater is installed in the cavity formed by the quartz tube or ceramic tube shell. The two ends of the carbon-ceramic composite electric heater are respectively provided with metal sheet electrodes, and the metal sheet electrodes are respectively connected to the corresponding metal rod electrodes. The electrode protrudes from the inside of the shell and a metal rod electrode sealing sleeve is provided between the protruding end and the shell. The metal rod passes through the metal rod electrode sealing sleeve, and the metal sheet electrode and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com