Rotary type microwave oven, system and method for preparing activated carbon

A microwave heating furnace and a technology for preparing activated carbon, which are applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of insufficient utilization of thermal energy resources, waste of resources, and low carbon recovery rate, and achieve the realization of thermal cycle. The effect of utilization, high recovery rate and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

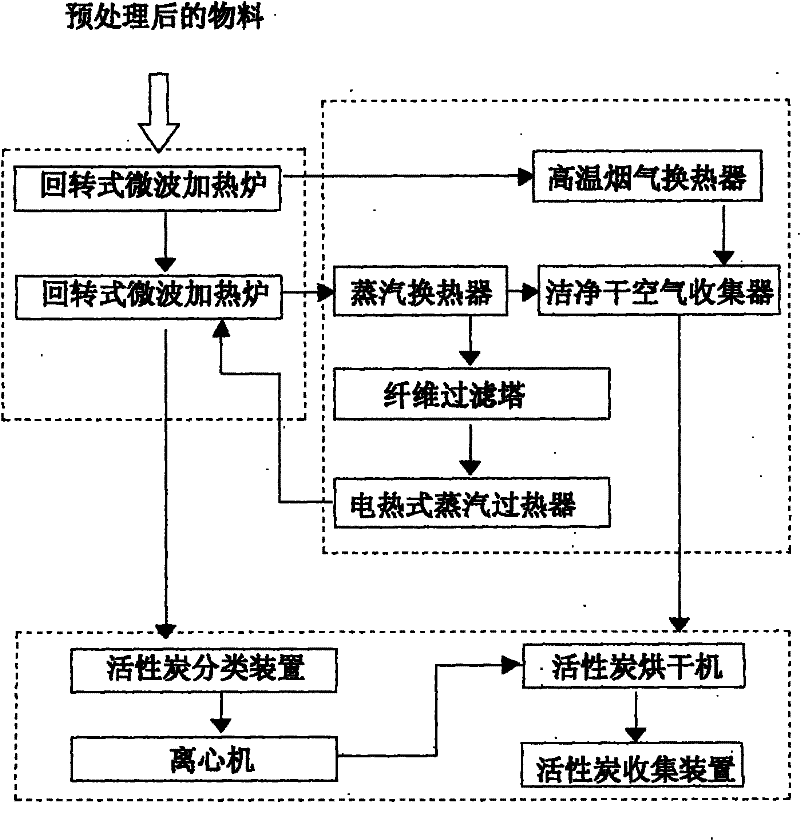

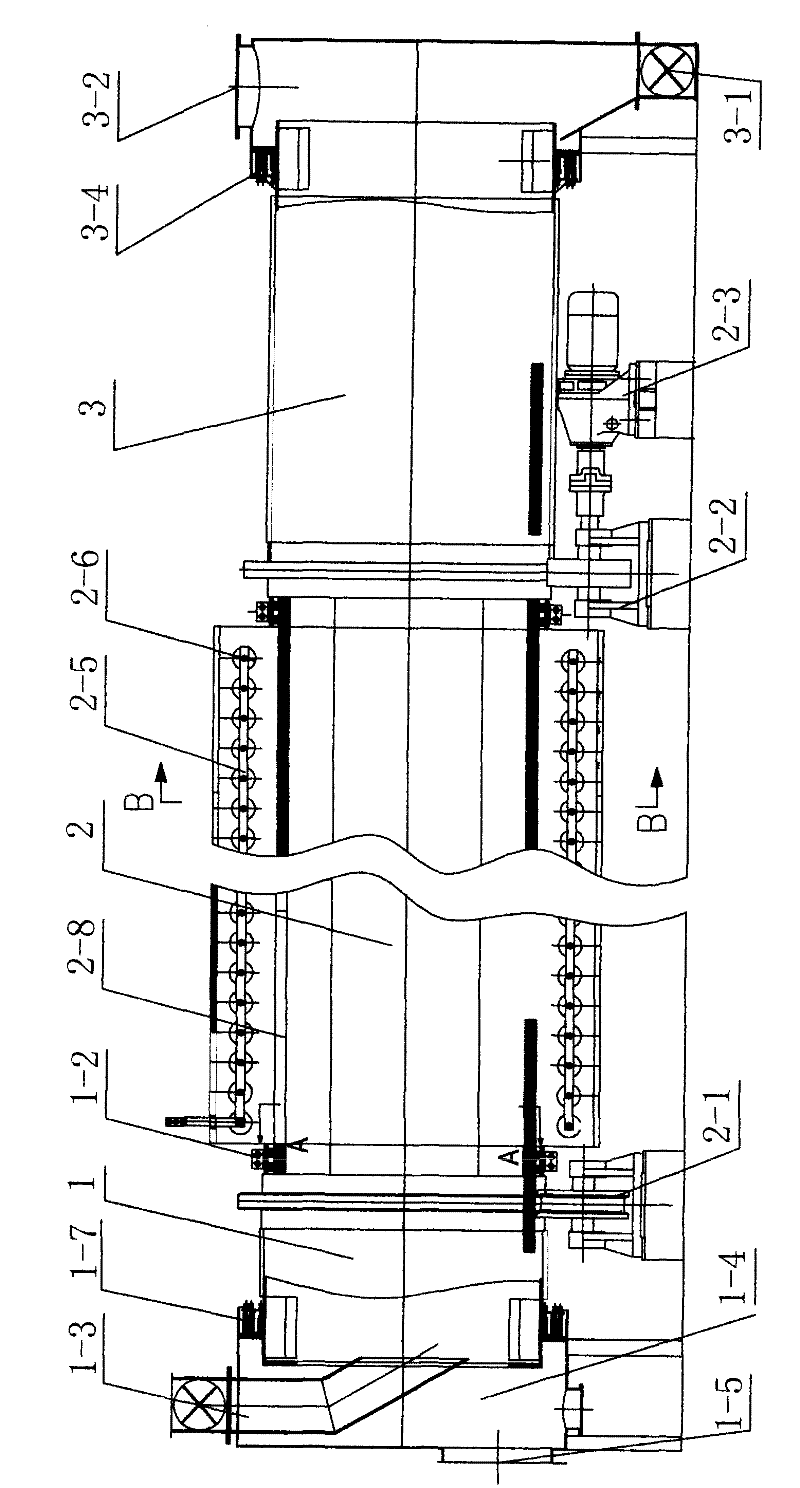

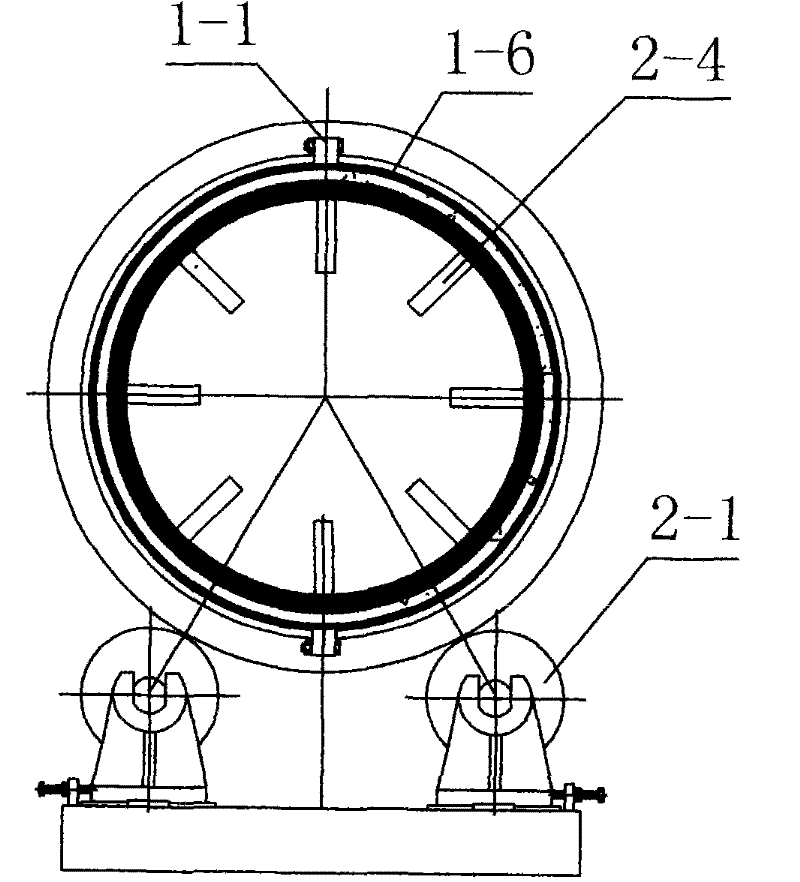

[0017] see figure 1 , figure 2 and image 3 The technical scheme adopted in the present invention is: a rotary microwave heating furnace for preparing activated carbon, which has a sealed shell cylinder structure ring and a matching microwave heater. The sealed shell cylinder adopts a rotary horizontal type, and the inner space of the sealed shell is set There are: distributing chamber 1, processing chamber 2 and cooling chamber 3, the three chambers are connected in turn, the front end of distributing chamber 1 is provided with feeding ports 1-3, the distributing chamber 1 and processing chamber 2 and the processing chamber 2 and cooling chamber 3 are respectively connected by means of hugging The hoop 1-1 is positioned and connected with the fastening flange 1-2, and the two ends of the processing chamber 2 are respectively connected with one end of the steel body where the distributing chamber 1 and the cooling chamber 3 are located, and are respectively arranged on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com