Cooking utensil with high cooking efficiency

A cooking utensil and high-efficiency technology, which is applied in the field of kitchen utensils, can solve the problems of reducing the cooking effect and user experience, and the inability to achieve uniform radiation heating of ingredients, and achieve the effects of improving cooking efficiency, shortening the cooking cycle, and uniform radiation heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

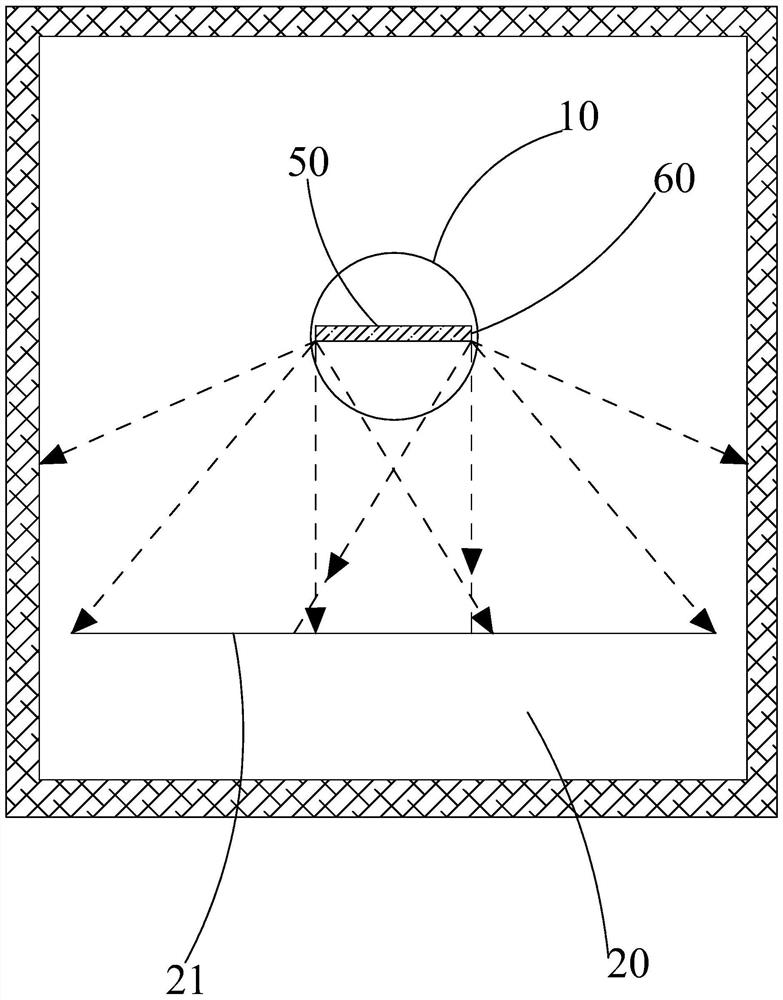

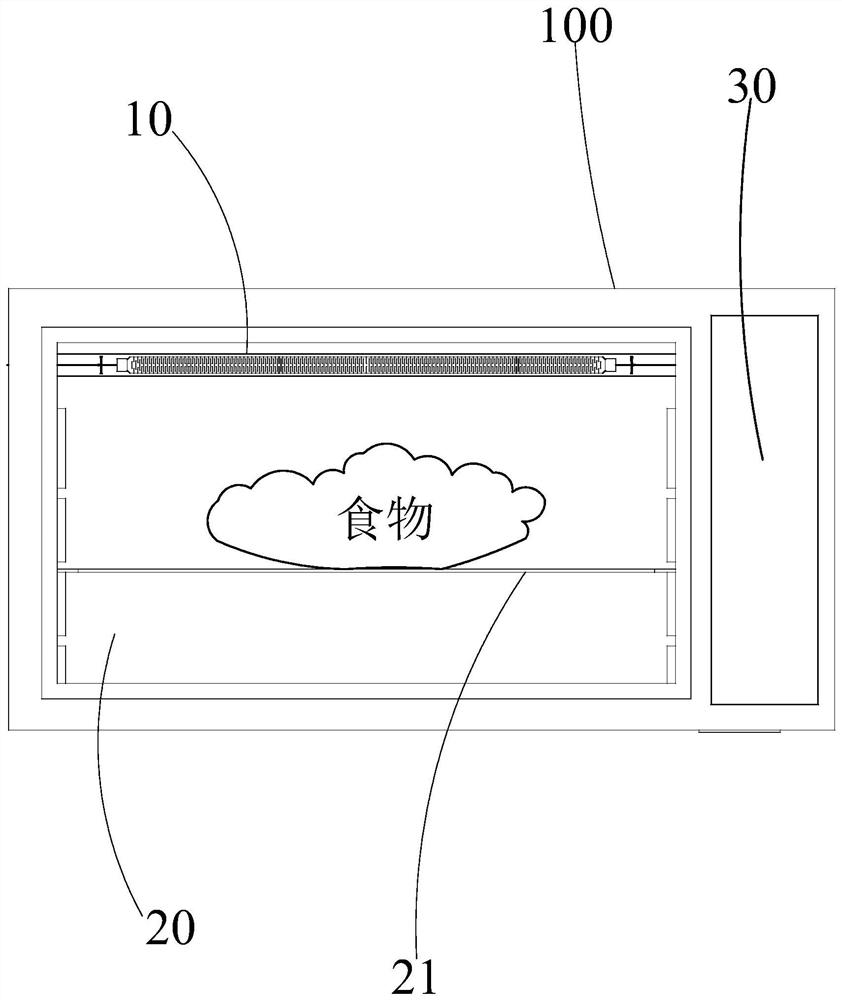

[0048] Such as figure 2 and 5As shown, the present invention provides a cooking utensil 100 with high cooking efficiency, including a cooking cavity 20 and a heating pipe 10, the heating pipe 10 includes a container 13, a sheet-shaped heating element 11 suspended in the container 13, and passing through the container 13 The power supply part 12 at both ends, the two ends of the heating element 11 are connected to the power supply part 12, and the heating tube 10 is installed on the top of the cooking cavity 20, so that the infrared rays emitted by the heating tube 10 can effectively penetrate into the food, reducing the cooking cavity 20. Other components in the oven can block infrared rays to improve cooking efficiency and energy saving.

[0049] In this embodiment, the heating element 11 includes a planar portion 112 and a linear side portion 111 , and the side portion 111 faces the food product placement area 21 in the cooking cavity. Due to the sheet-shaped heating elem...

Embodiment 2

[0072] Such as Figure 9 and 10 As shown, the second embodiment provided by the present invention is different from the first embodiment in that, in the second embodiment, the two ends of the heating element 11 are respectively provided with a second heating area 114, and the second heating area 114 The first heating area 113 with a temperature lower than the second heating area 114 is arranged between them, which further optimizes the heat radiation energy distribution of the food storage area 21, avoids the heat concentration in the central area of the food storage area 21, and makes the food storage area 21 The temperature distribution is more uniform,

[0073] Specifically, the heating element 11 includes a wide portion 115 and a narrow sub-section 116, the wide portion 115 and the narrow sub-portion 116 are arranged alternately in the length direction of the heating element 11, and the middle position of the wide portion 115 is provided with Slit 117, wherein the widt...

Embodiment 3

[0082] Such as Figure 12 and 13 As shown, the third embodiment provided by the present invention differs from the second embodiment in that in the third embodiment, the first heating area 113 is a conductive part electrically connected to the end of the second heating area 114, The conductive part is a molybdenum rod, and the molybdenum rod is fixed and electrically connected to the end of the second heating area 114 through a holder, and the material of the holder is molybdenum metal. The resistance of the molybdenum rod is very small, so the calorific value of the molybdenum rod is almost negligible, which avoids the heat concentration in the central area of the food storage area 21, so that the temperature distribution of the food storage area 21 is more uniform; at the same time, the heating element 11 Segmented arrangement, during the long-term use of the heating element 11, can avoid the sagging phenomenon of the heating element 11 due to softening and its own gravit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com