Side fired reformer

A reforming furnace and reforming tube technology, which is applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of uneven longitudinal distribution of furnace tube wall temperature, and achieve a simple hanging structure, simple expansion of the tube system, and simple furnace tube expansion. The effect of uniform wall temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

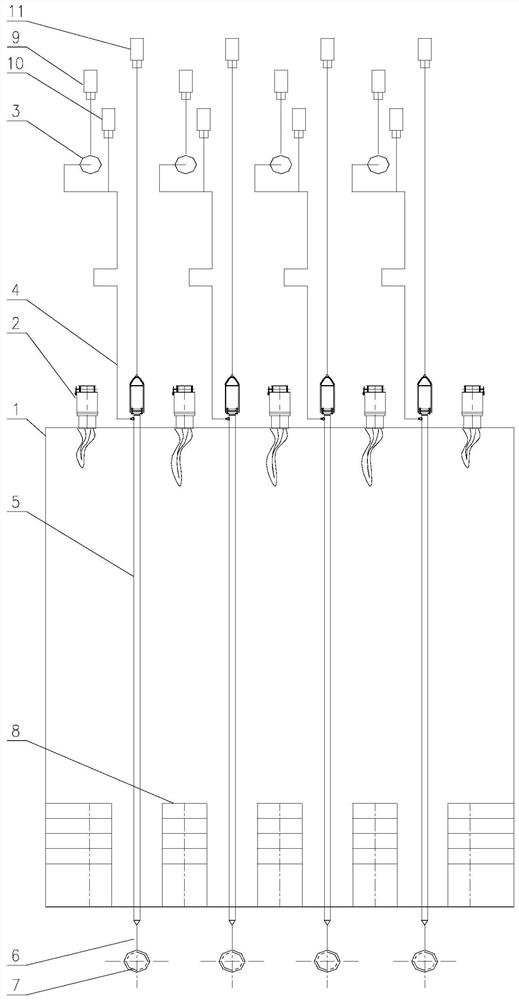

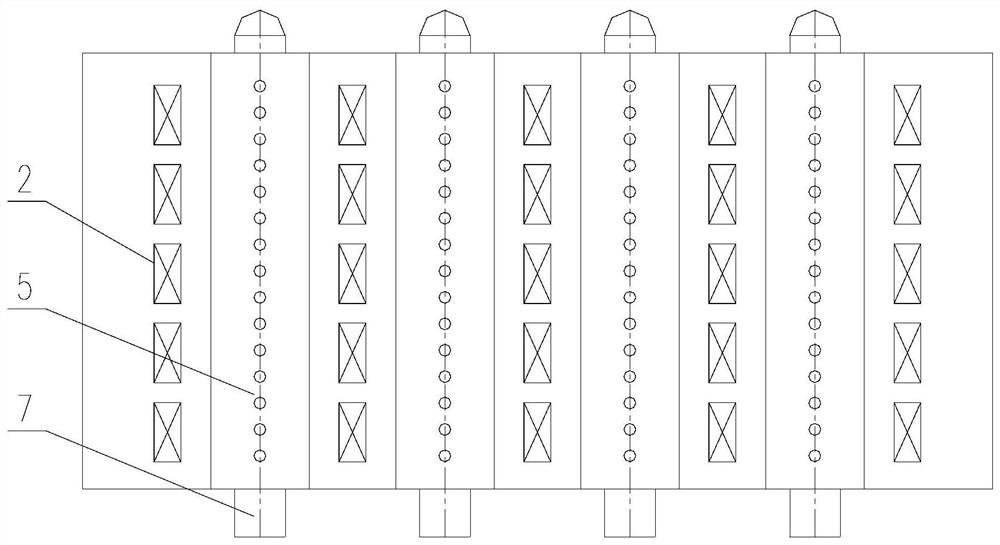

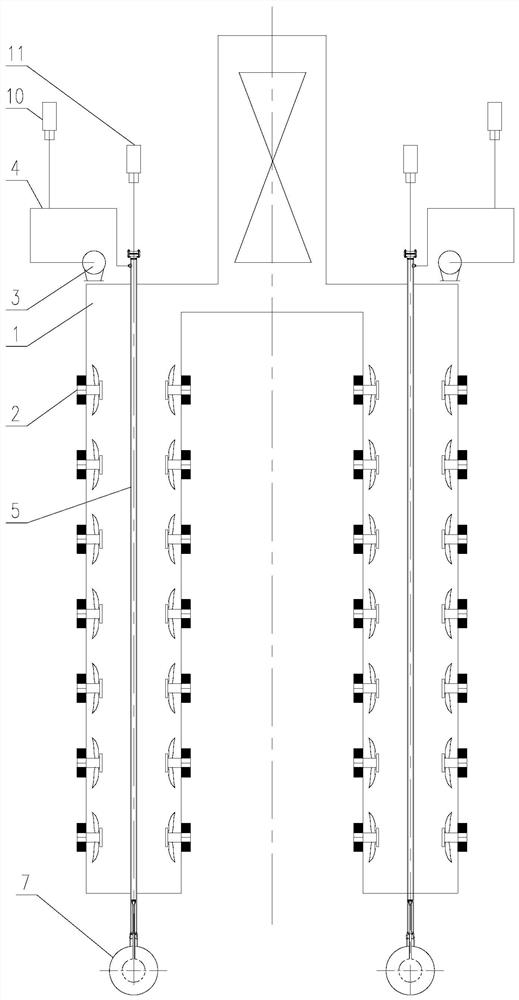

[0070] image 3 A front view of a side-firing converter according to one embodiment of the present invention is shown. Figure 4 A side view of a side-firing converter according to one embodiment of the invention is shown. Figure 5 A top view of a side-firing converter according to one embodiment of the present invention is shown. Figure 6a -c shows a detailed node diagram of a side-firing reformer according to an embodiment of the present invention.

[0071] Such as image 3 , 4 , 5, 6a, 6b and 6c, the side-burning converter includes: a radiation section and a radiation-to-convection hot flue 13, wherein the radiation furnace 12 includes a symmetrically arranged inlet furnace and an outlet furnace, and the furnace is respectively provided with The inlet reformer tube 16 and the outlet reformer tube 18 are multi-channel parallel, and the height of the tube row is 50% of the single-tube reaction length of the original typical design reformer. The bottom of the inlet conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com