LED lamp filament assembly, method for forming LED lamp filament bulb and LED lamp filament bulb

A technology of LED filaments and components, applied in semiconductor devices of light-emitting elements, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve the problem of reduced photoelectric conversion efficiency, low application power, and lack of replaceable standard light sources and other issues, to achieve the effect of improving the light extraction efficiency and increasing the heat radiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

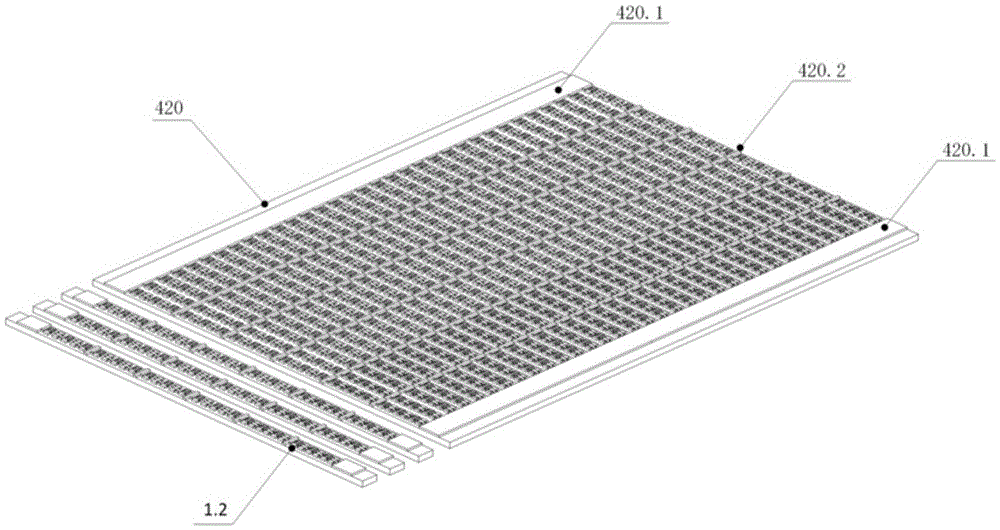

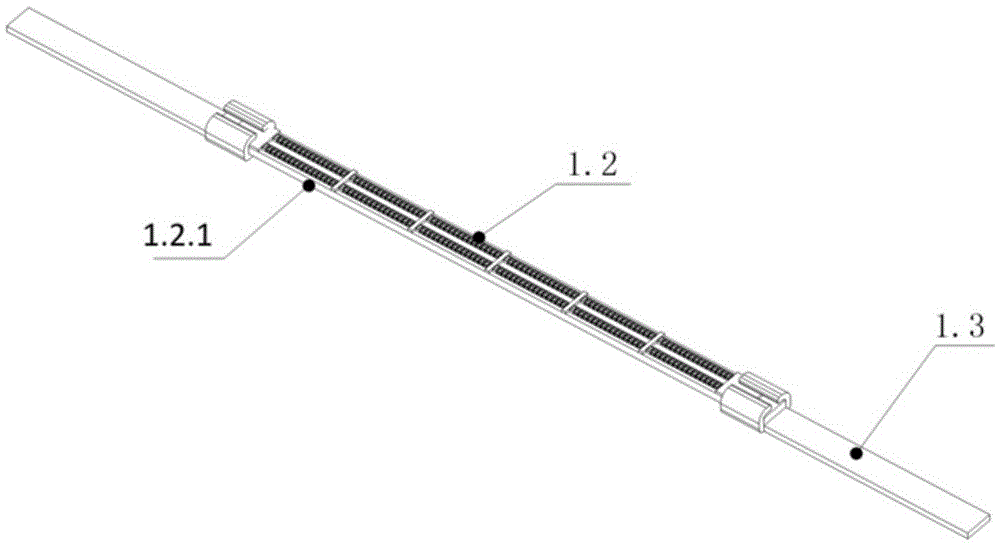

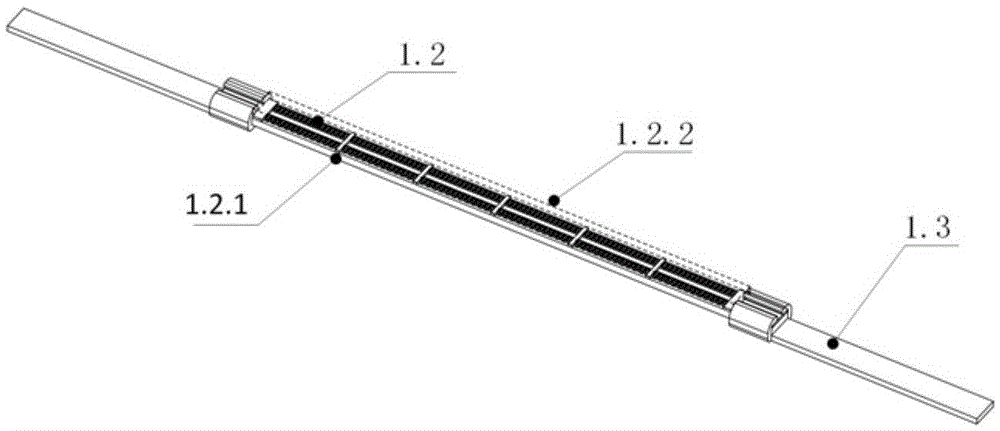

[0045] Example. An LED filament assembly, such as Figure 4 and Figure 5 As shown, it includes one or more LED filaments 1.1 with electrical connection terminals 1.3 at both ends, and the electrical connection terminals 1.3 at both ends of the LED filament 1.1 are respectively connected to two heat-conducting terminal brackets 1.4. The LED filament 1.1 includes an LED filament module 1.2 and electrical connection terminals 1.3 at both ends, and the LED filament module 1.2 includes a strip or block filament module substrate 1.2.1 and filament module substrate 1.2.1. LED chips are connected in series, and the LED filament module 1.2 is provided with a transparent package. In order to facilitate heat transfer, the part of the electrical connection terminal 1.3 close to the terminal bracket 1.4 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com