Stereo heating disinfection cabinet based on thick film heating

A thick-film heating and three-dimensional heating technology, which is applied in heating, disinfection, cleaning of household items, etc., can solve the problems of long disinfection or drying process, small heat radiation area, and easily damaged tableware, etc., to achieve fast heating speed, The effect of wide heat radiation area and fast heat radiation diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

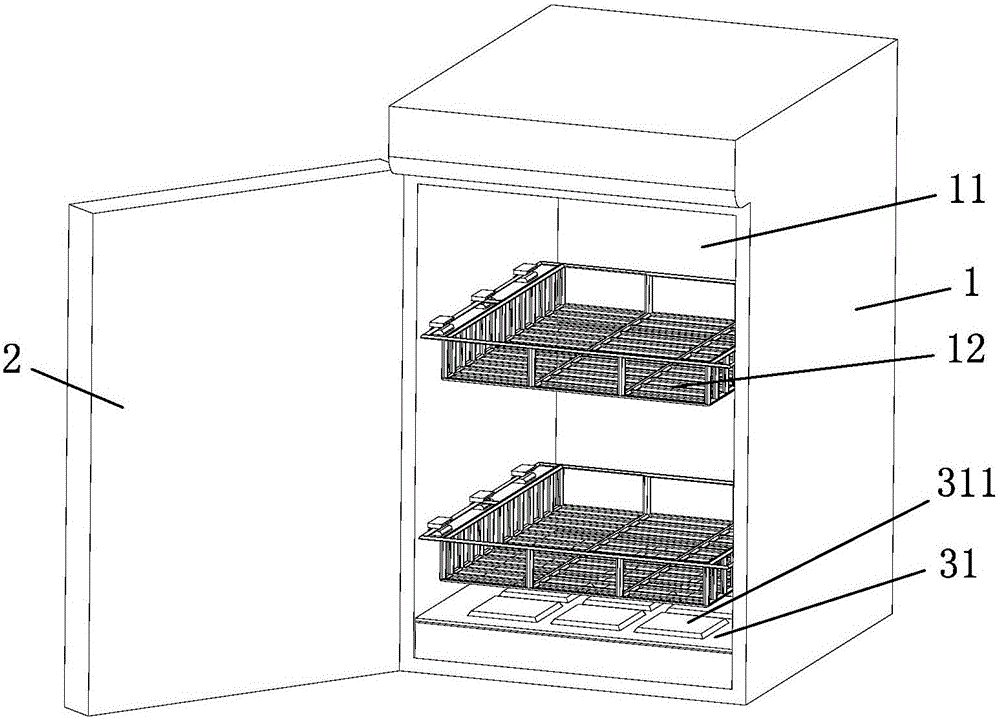

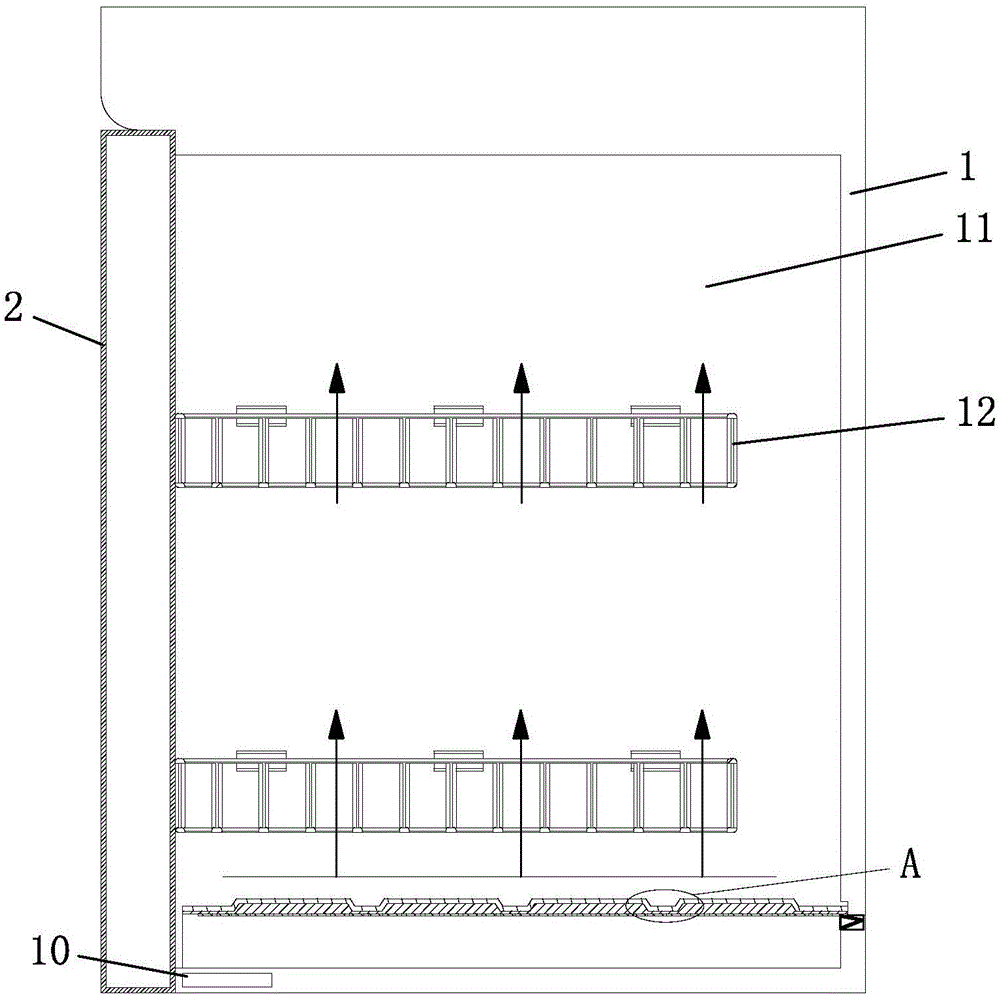

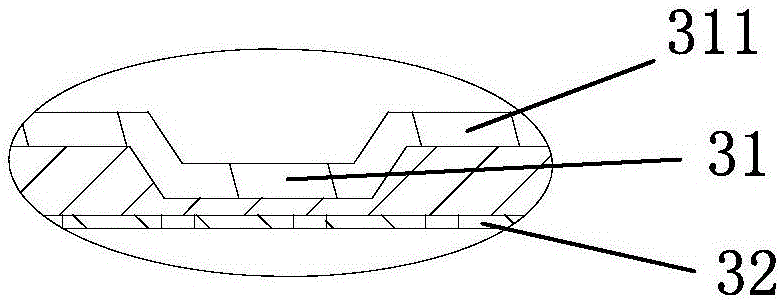

[0031] see Figure 1-Figure 4 , the three-dimensional heating and disinfection cupboard based on thick film heating, including a cabinet body 1 provided with a disinfection chamber 11, a cabinet door 2 connected to the cabinet body 1, and several layers of racks 12 are detachably arranged in the disinfection chamber 11 , The bottom of the disinfection chamber 11 is provided with a thick film heating plate, and the thick film heating plate includes a main heating substrate 31 and a main thick film heating circuit 32 printed on its bottom surface. Although the thick film heating plate is located at the bottom of the disinfection chamber 11, due to the structural characteristics of the thick film heating plate, it is determined that it will not have a large amount of heat radiating to the outside of the cabinet body 1. Only bottom-up three-dimensional heating is performed, with fast heating speed, high efficiency and uniform heat, which can effectively shorten the disinfection or...

no. 2 example

[0038] see Figure 5-Figure 8 The main difference between this three-dimensional heating and disinfection cupboard based on thick film heating and the first embodiment is that additional thick film heating plates can be set under some or all of the shelves 12. In this embodiment, the disinfection chamber 11 is detachably provided with upper and lower two-layer shelf 12, and the bottom of the shelf 12 of the upper floor is provided with another thick film heating plate (such as Figure 7 with Figure 8 As shown), the thick-film heating plate includes a secondary heat-conducting substrate 33 and a secondary thick-film heating circuit 34 printed on its bottom surface. When the volume of the disinfection chamber 11 is large or the height is high, a thick-film heating plate is arranged under the shelf 12 to ensure that the overall heating and disinfection process of the disinfection chamber 11 is more uniform and reliable, and is especially suitable for commercial disinfection cup...

no. 3 example

[0043] see Figure 9 The main difference between this three-dimensional heating and disinfection cupboard based on thick film heating and the first embodiment is that a hot air circulation device is provided on the cabinet body 1; The hot-blast duct 41 at the end is provided with a hot-blast circulation fan 42 on the hot-blast duct 41 . The hot air circulation device can draw air from the top of the disinfection chamber 11, and blow air from the bottom of the disinfection chamber 11, so that a bottom-up circulating airflow is formed in the disinfection chamber 11, and the convection in the disinfection chamber 11 is accelerated, so that the temperature in the disinfection chamber 11 More uniform, further improving the high-temperature disinfection and drying effect of the disinfection cupboard.

[0044] Other unmentioned parts are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com