Far infrared reflector of integrated structure and manufacturing method of far infrared reflector

A reflector and far-infrared technology, which is applied in the field of far-infrared reflector and its manufacturing, can solve the problems of cumbersome, complicated operation, and many parts, and achieve the effect of reducing online operations, reducing production processes, and reducing the chance of work-related injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

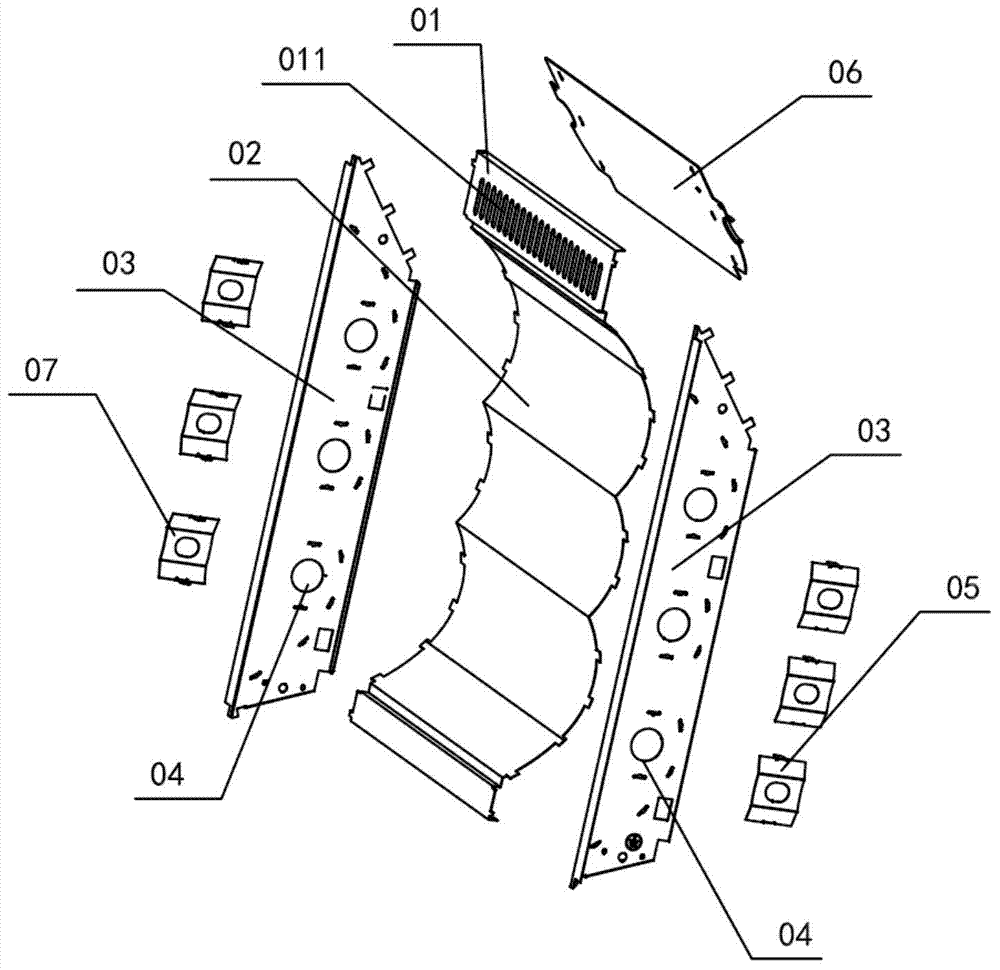

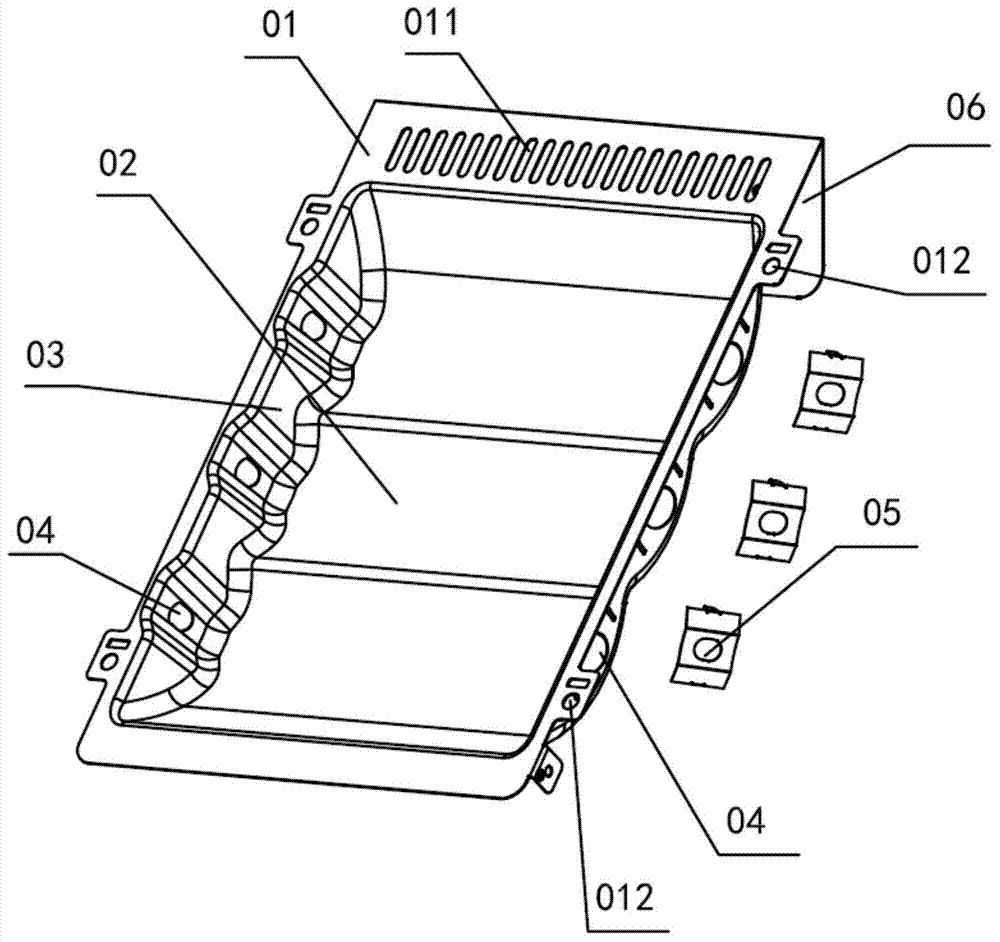

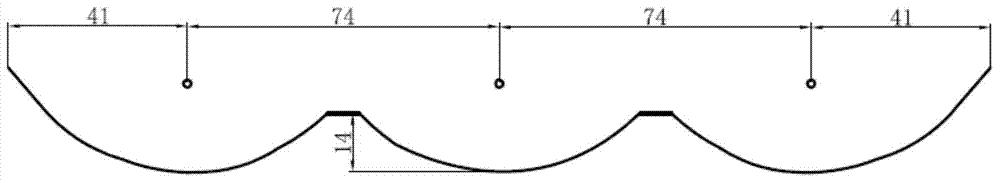

[0037] The structural diagram of the far-infrared reflector of the present invention's integrated structure figure 2 , including reflector mounting surface 01, reflector 02, two reflector sides 03, heat pipe installation hole 04, buckle 05 and heat shield 06, reflector mounting surface 01 is provided with a plurality of cooling holes 011 and four There are three installation holes 012 and buckle 05 in total. The buckle 05 covers the heating pipe installation hole 04 to limit the outward movement of the heat pipe in the heat pipe installation hole 04; the reflector mounting surface 01 is a hollow structure, and the reflector 02 is a parabolic arc surface structure, which is set on the hollow of the reflector mounting surface 01. A total of three parabolic arc surface structures are arranged on the reflector 02; There are 6 heat pipe installation holes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com