Microwave heating type cracking furnace

A microwave heating and cracking furnace technology, applied in the field of activation furnace, can solve the problems of high energy consumption, incomplete equipment function, insufficient carbon reduction, etc., and achieve the effects of large heat radiation area, improved applicability, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

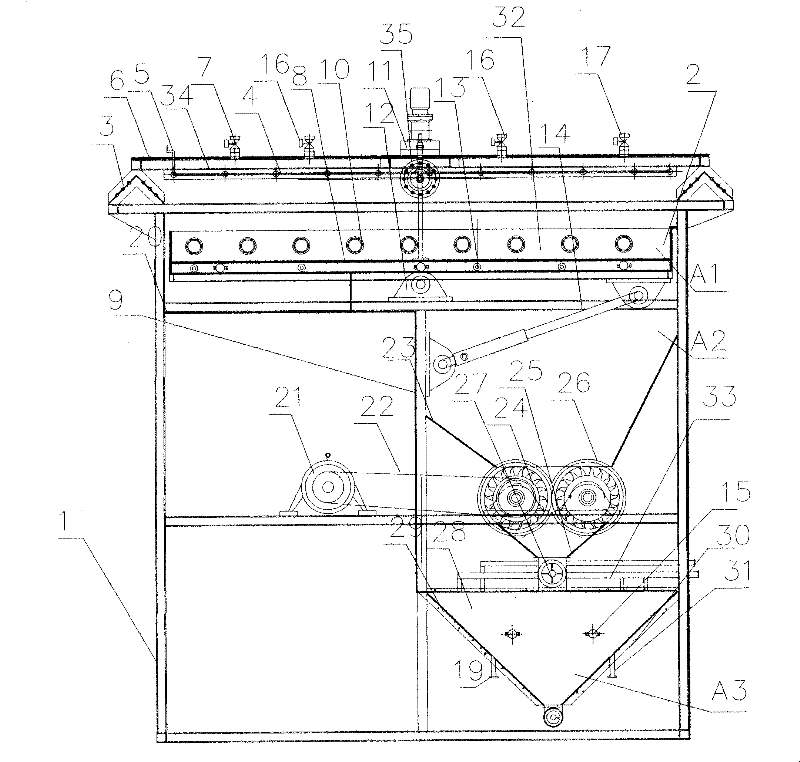

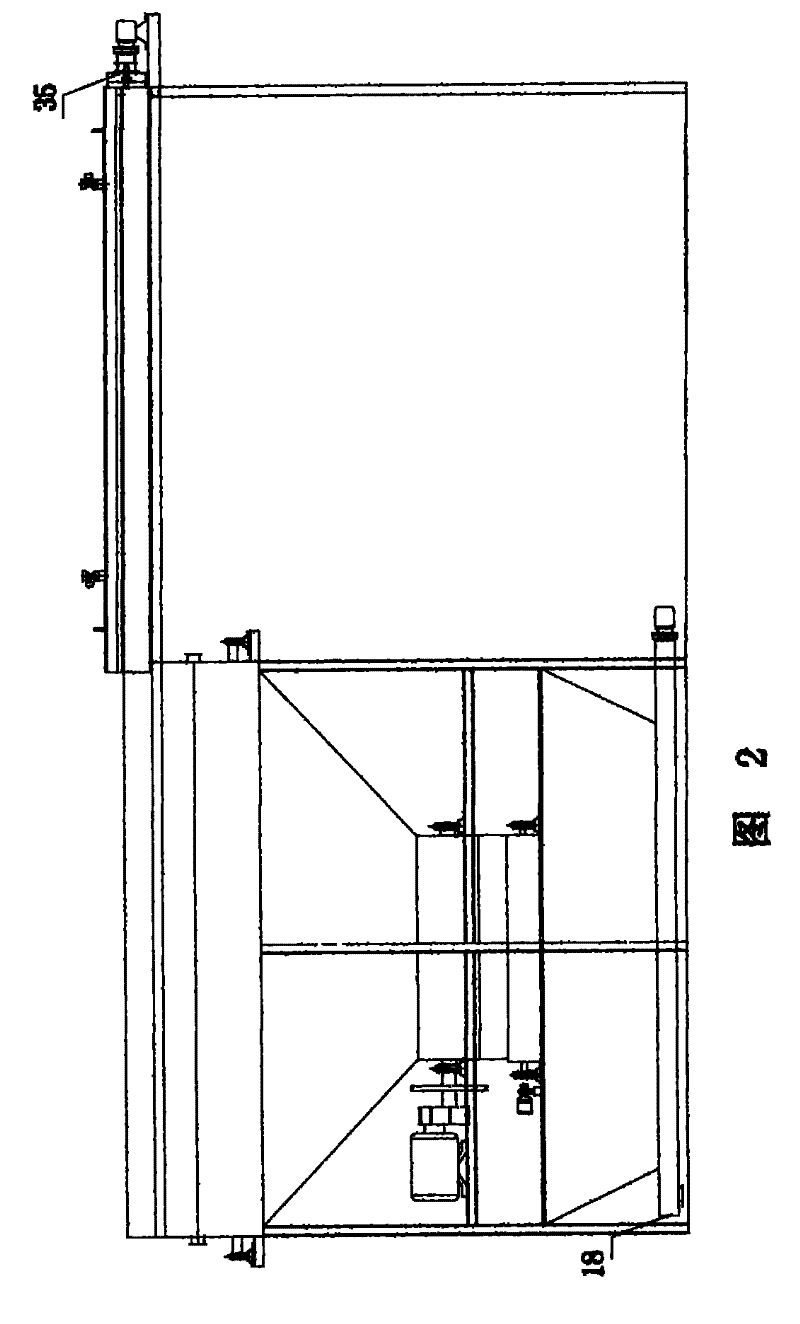

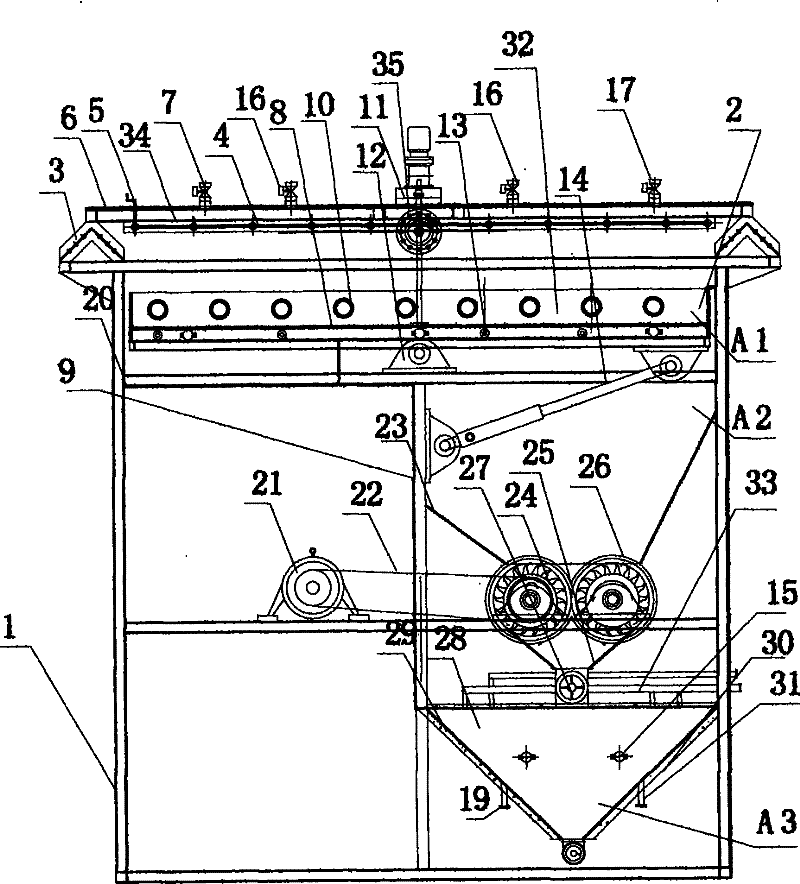

[0011] The present invention proposes a microwave heating type cracking furnace, and the adopted technical scheme is: a microwave heating type cracking furnace, the structure includes a closed heating furnace body and matching heating, pressure maintaining and pyrolysis atmosphere maintaining mechanisms, and adopts pyrolysis , carbonization, and activation integrated structure: the structure includes two parts: the sliding sealing cover plate and the furnace body located on the top of the furnace. Furnace chamber A1, the activation chamber A3 located below the pyrolysis furnace chamber A1, the sliding sealing cover plate on the top of the pyrolysis furnace chamber A1 is provided with an inverted V-shaped groove track with an inlaid sealing material, and the matching set on the upper end of the pyrolysis furnace body The inverted V-groove track forms a sliding and sealing friction pair 3. The structure includes a shell-type frame 1, and the space in the furnace is separated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com