Heating element with porous ceramic coating

A technology of porous ceramics and heating elements, which is applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve the problems of limited surface area, increase the surface roughness of heating elements, and cannot change the thermal emissivity of materials, etc. , to prolong the service life, not easy to peel off or crack, and reduce the use temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

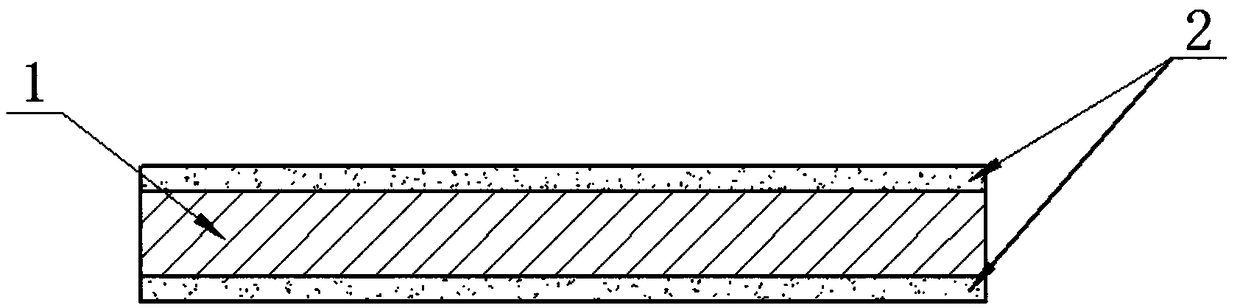

[0035] The present invention also provides a method for preparing a heating element with a porous ceramic coating, preferably comprising the following steps:

[0036] A) mixing metal powder and ceramic powder to obtain a coating material; the mass fraction of the metal powder in the coating material is 0% to 50%;

[0037] B) coating the coating material on the surface of the metal substrate to obtain a semi-finished product;

[0038] C) Sintering the semi-finished product to obtain a heating element with a cermet composite coating.

[0039]In the present invention, the type and amount of the metal powder are consistent with the type and amount of the metal phase described above, and the type and amount of the ceramic powder are consistent with the type and amount of the ceramic phase described above , which will not be repeated here.

[0040] In the present invention, the metal matrix is preferably processed into a size suitable for the heating cavity, and then coated.

...

Embodiment 1

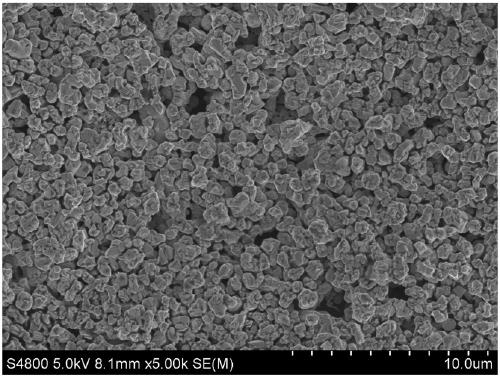

[0052] Firstly, the size of the tungsten sheet or tungsten plate is processed according to the drawings to obtain a tungsten or tungsten alloy heating element substrate suitable for the MOCVD reaction chamber. Prepare tantalum carbide ceramic coating raw materials, wherein tantalum carbide powder: tungsten powder (ie metal powder) = 100:0 (weight ratio), and then use cold spray equipment to carry out cold spray on the tungsten or tungsten alloy heating element substrate, The thickness of the tantalum carbide coating is about 20 μm, and it is dried after spraying. At this time, a composite body of the tantalum carbide ceramic coating and the matrix of the tungsten or tungsten alloy heating element is obtained. The complex is sintered in a vacuum high-temperature sintering furnace, the sintering temperature is 1700°C, and the holding time is 90 minutes. According to the heating element obtained after the implementation of this embodiment, the bonding strength between the tantalu...

Embodiment 2

[0054] Firstly, the size of the tungsten sheet or tungsten plate is processed according to the drawings to obtain a tungsten or tungsten alloy heating element substrate suitable for the MOCVD reaction chamber. The ceramic phase powder for coating is TaC powder and ZrC powder, the metal binder phase is tungsten powder, and the mass ratio of the three is 50:50:10. Then use cold spraying equipment to carry out cold spraying on the tungsten or tungsten alloy heating element substrate, and the thickness of the coating is 50 μm. The complex is dried in an oven at 120°C for 30 minutes, and then sintered in a vacuum high-temperature sintering chamber at 1500°C for 90 minutes. For the heating element prepared according to this embodiment, the bonding strength between the coating and the heating element substrate is 31 MPa, and the heat radiation rate of the heating element is lower than that of Example 1, which is 0.63. The coating porosity was 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com