Shell of terminal equipment and processing method of shell

A technology of terminal equipment and processing method, applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, etc., can solve problems such as poor heat dissipation effect of terminal equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

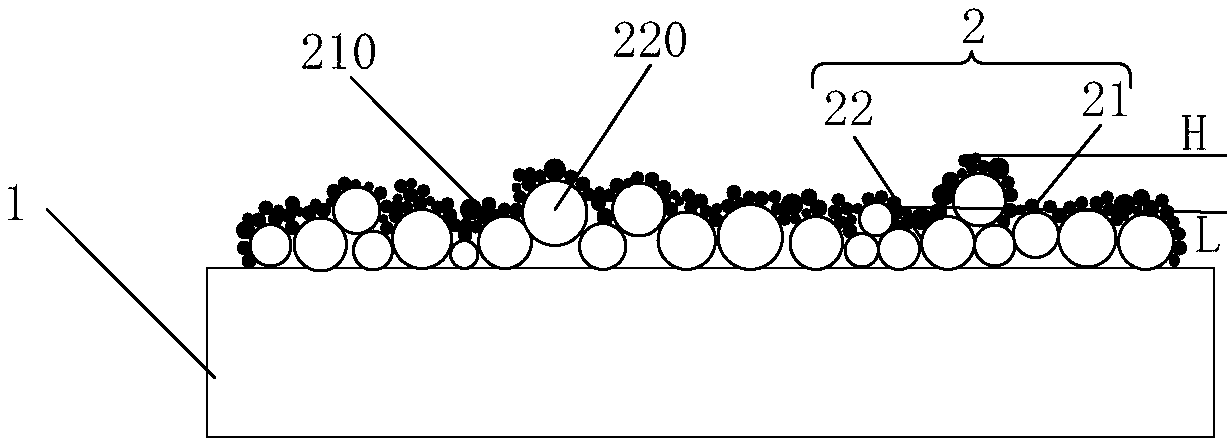

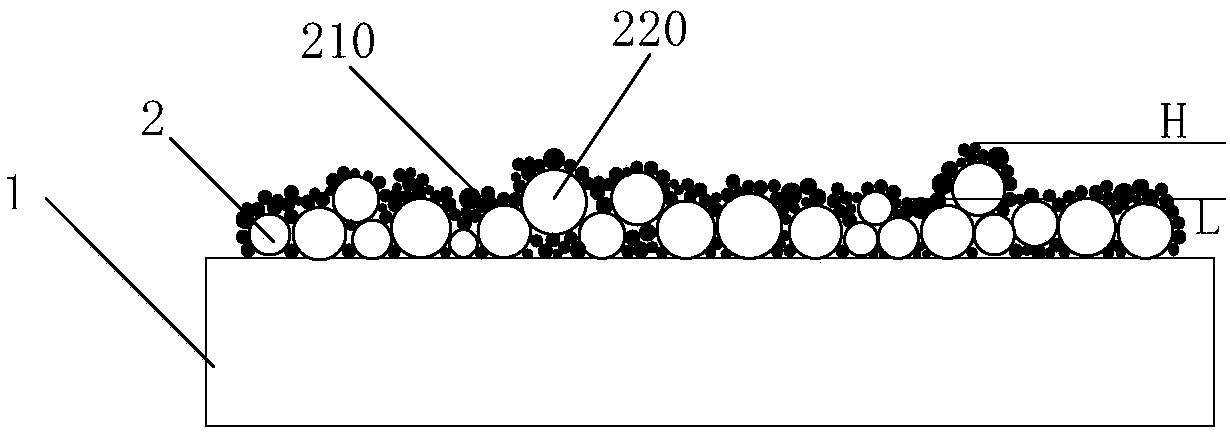

[0035] This embodiment provides a processing method for a terminal device housing, including:

[0036] Water-based polyurethane resin, surfactant, graphite, metal copper particles and deionized water are according to the mass parts of 25 parts of water-based polyurethane resin, 0.2 parts of surfactant, 10 parts of graphite, 65 parts of deionized water and 10.4 parts of metal copper particles Mix evenly to form a thermally conductive coating;

[0037]The heat-conducting paint is sprayed onto the surface of the housing body by means of electrostatic spraying.

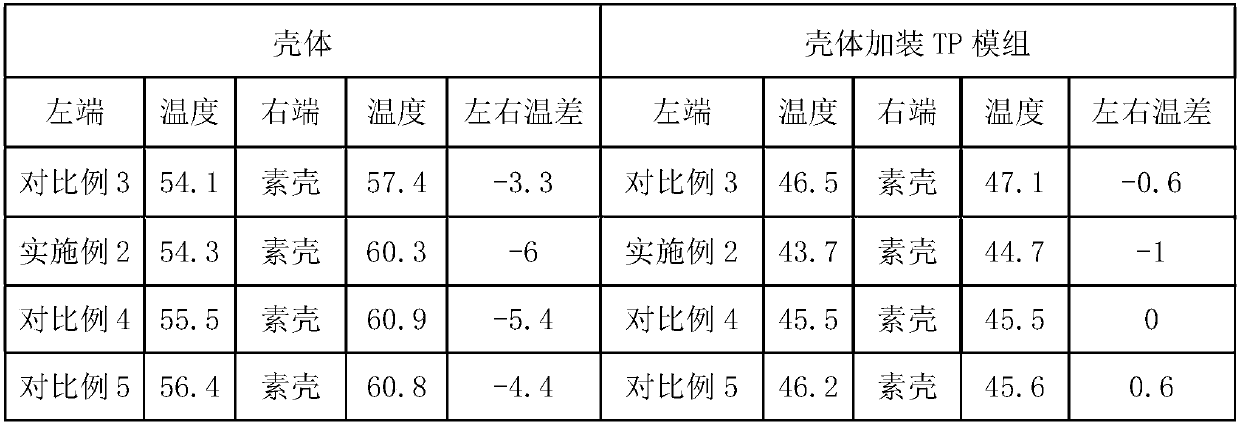

Embodiment 2

[0039] This embodiment provides a processing method for a terminal device housing, including:

[0040] Water-based polyurethane resin, surfactant, graphite, metal copper particles and deionized water are according to the mass parts of 30 parts of water-based polyurethane resin, 0.5 parts of surfactant, 8 parts of graphite, 60 parts of deionized water and 14 parts of metal copper particles Mix evenly to form a thermally conductive coating;

[0041] The heat-conducting paint is sprayed onto the surface of the left side of the upper casing of the mobile phone by means of electrostatic spraying.

Embodiment 3

[0043] This embodiment provides a processing method for a terminal device housing, including:

[0044] Water-based polyurethane resin, surfactant, graphite, metal copper particles and deionized water are according to the mass parts of 30 parts of water-based polyurethane resin, 0.5 parts of surfactant, 8 parts of graphite, 60 parts of deionized water and 14 parts of metal copper particles Mix evenly to form a thermally conductive coating;

[0045] The heat-conducting paint is sprayed onto the surfaces of the upper and lower casings of the mobile phone by means of electrostatic spraying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com