Independently controllable high-temperature equipment provided with multiple vacuum cavities

A technology for vacuum chambers and storage equipment, which can be used in packaging under vacuum/special atmosphere, packaging objects under special gas conditions, food heating containers, etc. It can solve problems such as equipment cost and energy consumption increase, and inconvenience in testing or production , to achieve the effect of short vacuuming time and large heat radiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

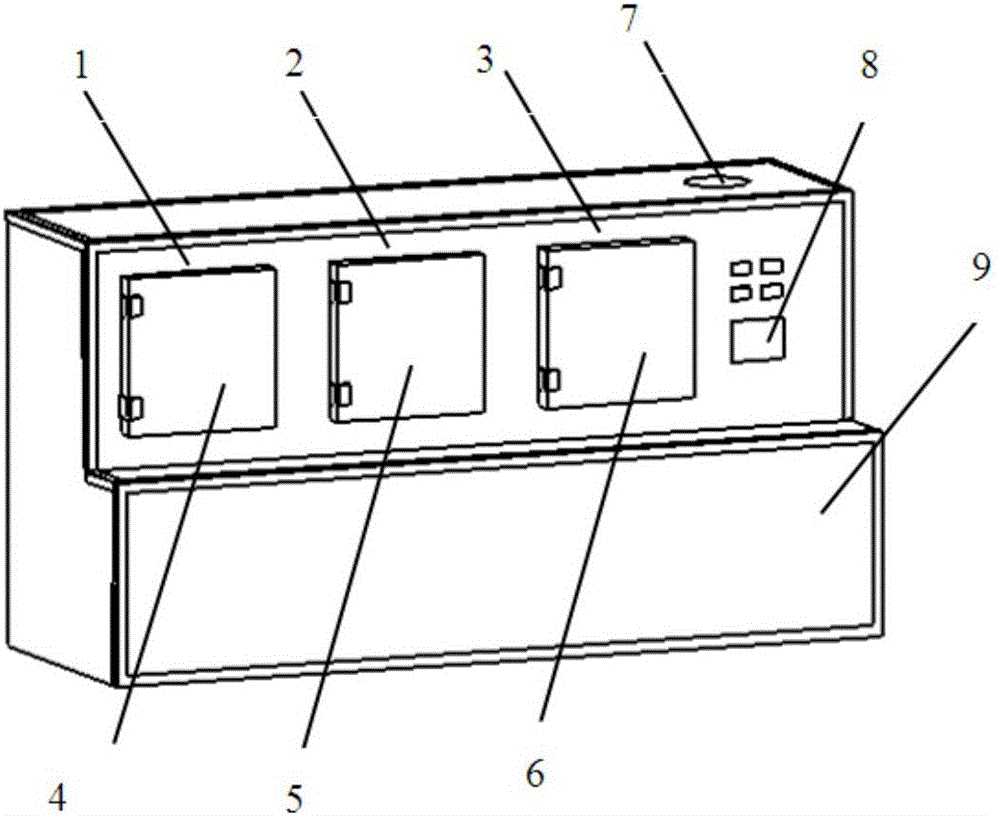

[0023] Such as Figure 1~3 As shown, an independently controllable multi-chamber vacuum high-temperature storage device includes a first vacuum chamber 1, a second vacuum chamber 2, a third vacuum chamber 3, a first airtight door 4, and a second airtight door 5 , the third airtight door 6, vacuum system 7, display control system 8 and cabinet 9;

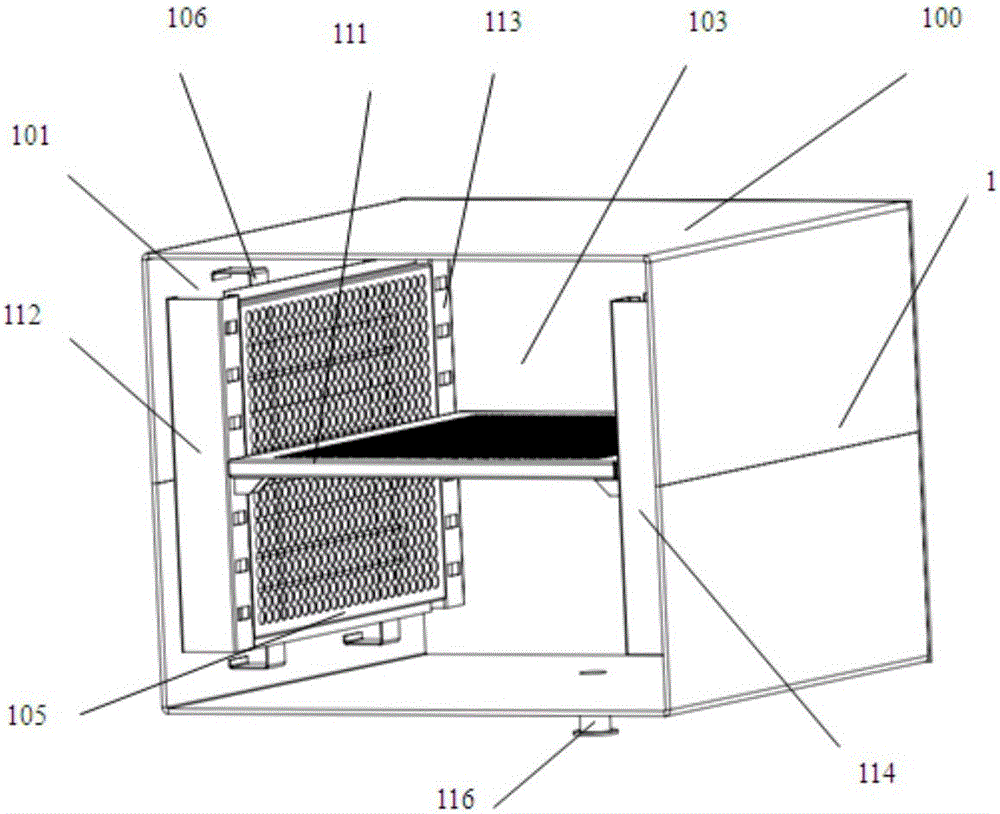

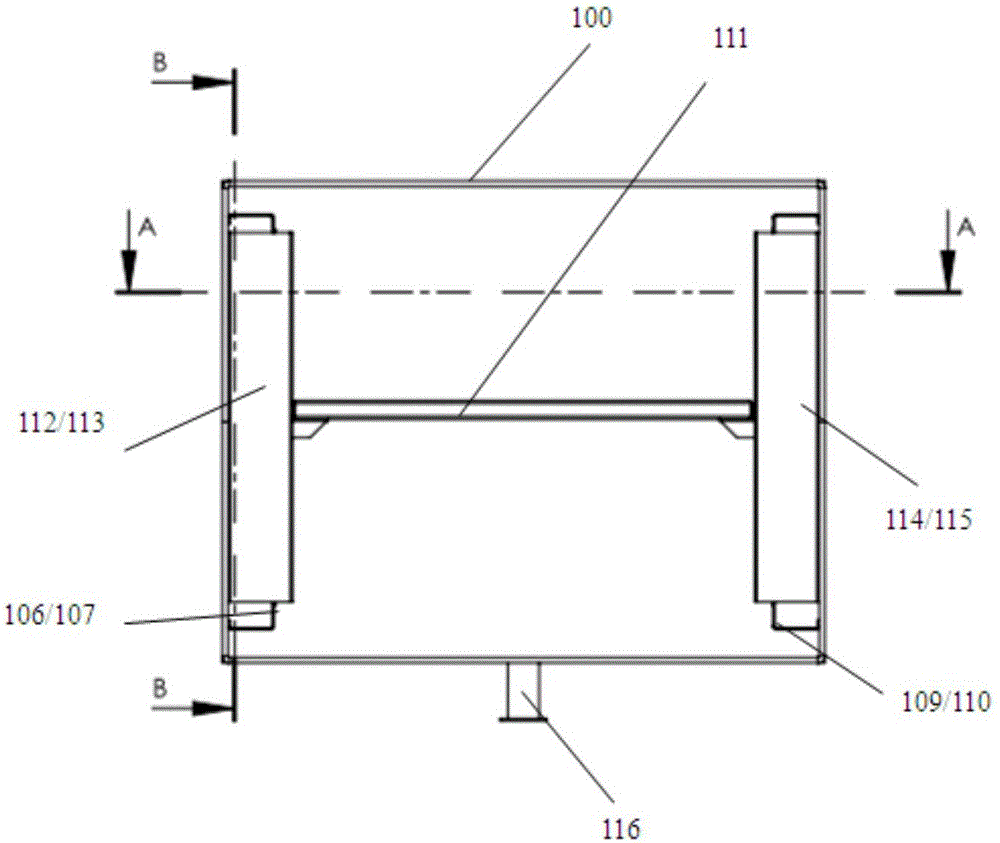

[0024] The left heat radiation chamber 101 is composed of a vacuum chamber stainless steel wall, a left heating tube 104, and a left heat radiation orifice plate 105. The left heating tube 104 is fixed on the left front heating tube fixing frame 106 and the left rear heating tube fixing frame On 107; the right heat radiation chamber 102 is made up of the stainless steel wall of the vacuum chamber, the right heating tube 108, and the right heat radiation orifice 109, and the right heating tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com