High-temperature nano radiation coating for heating furnace and preparation process thereof

A heating furnace and radiation coating technology, applied in the field of high temperature radiation coating, can solve the problems of short service life, limited coating wavelength range, low emissivity, etc., and achieve the effects of smooth surface, shortened heating time, and improved temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

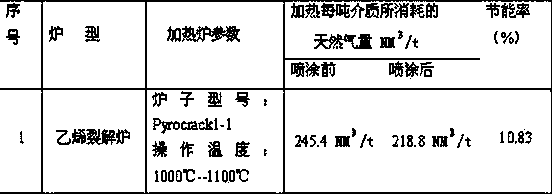

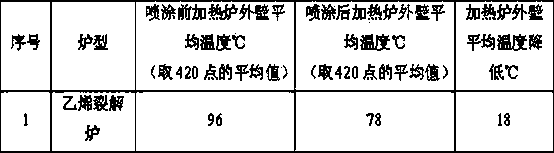

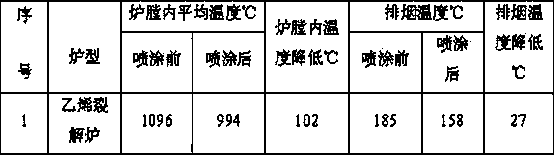

Examples

Embodiment 1

[0045] (a) mixing components selected from the group consisting of: ZrO 2 , BN, SiC, MgO, La2O3, MnO 2 、Cr 2 o 3 , BeO and zircon, mix the components according to the following mass percentage composition: ZrO 2 8%, BN12%, SiC 10%, MgO42%, La 2 o 3 10%, Cr 2 o 3 5%, BeO4%, zircon 9%, mix the mixed components with water according to 1:1.5, and make slurry;

[0046] (b) Evenly paint the slurry prepared in the above steps on the mold with a thickness of 3mm, and dry it naturally for 12 hours to make thin slices, put the prepared thin slices into a calciner, calcinate at 1800°C for 3 hours, take them out and use Rapid cooling with 3KPa compressed air to obtain blanks;

[0047] (c) Put the tablet into the pulverizer for preliminary crushing, and the particle size of the obtained primary powder material is ≤5mm;

[0048] (d) Put the primary powder material into the fine grinding pulverizer for fine grinding and pulverization, put the fine pulverized material into the sievi...

Embodiment 2

[0054] (a) mixing components selected from the group consisting of: ZrO 2 , BN, SiC, MgO, La2O3, MnO 2 、Cr 2 o 3 , BeO and zircon, the components are mixed according to the following mass percentage: ZrO 2 5:%, BN15%, SiC 15%, MgO30%, La 2 o 3 14%, Cr 2 o 3 5%, BeO6%, zircon 10%, mix the mixed components with water according to 1:1.5, and make slurry;

[0055] (b) Evenly paint the slurry prepared in the above steps on the mold with a thickness of 3mm, and dry it naturally for 12 hours to make thin slices, put the prepared thin slices into a calciner, calcinate at 2200°C for 3 hours, take them out and use Rapid cooling with 3KPa compressed air to obtain blanks;

[0056] (c) Put the tablet into the pulverizer for preliminary crushing, and the particle size of the obtained primary powder material is ≤5mm;

[0057] (d) Put the primary powder material into the fine grinding pulverizer for fine grinding and pulverization, put the fine pulverized material into the sieving m...

Embodiment 3

[0064] (a) mixing components selected from the group consisting of: ZrO 2 , BN, SiC, MgO, La2O3, MnO 2 、Cr 2 o 3 , BeO and zircon, mixing said components according to the following percentage composition: ZrO 2 6%, BN12%, SiC 12%, MgO34%, La 2 o 3 15%, Cr 2 o 3 6%, BeO4%, zircon 11%, mix the mixed components with water according to 1:1.5, and make slurry;

[0065] (b) Evenly paint the slurry prepared in the above steps on the mold with a thickness of 3 mm, and dry it naturally for 12 hours to make thin slices, put the prepared thin slices into a calciner, and calcinate them at 2800°C for 5 hours, take them out Rapid cooling with 3KPa compressed air to obtain blanks;

[0066] (c) Put the tablet into the pulverizer for preliminary crushing, and the particle size of the obtained primary powder material is ≤5mm;

[0067] (d) Put the primary powder material into the fine grinding pulverizer for fine grinding and pulverization, put the fine pulverized material into the sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com