Polyaniline epoxy silicone graphene heat dissipation electrostatic conductive paint

A technology of polyaniline epoxy and epoxy silicone, which is applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems affecting the performance and life of electronic products, the temperature rise of components and circuits, and insufficient heat dissipation. Achieve the effect of improving heat dissipation efficiency and its comprehensive performance, improving thermal conductivity and thermal radiation rate, and improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

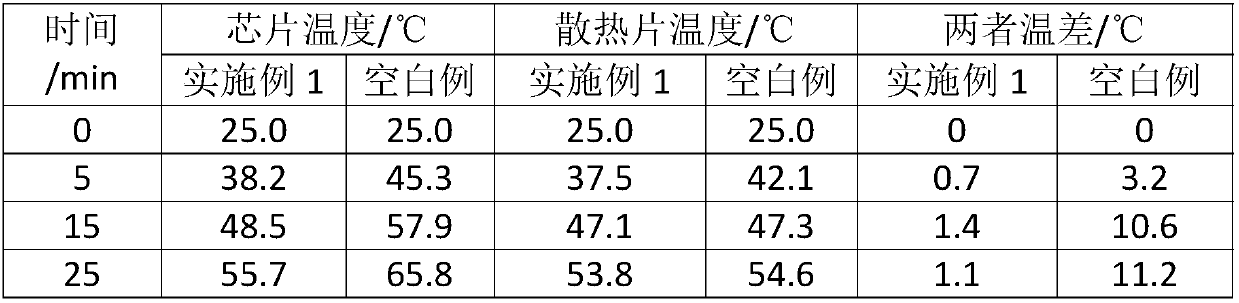

Embodiment 1

[0028] Polyaniline epoxy organosilicon graphene heat-dissipating and conductive electrostatic coating, comprises main agent A and curing agent B, and the weight ratio of described main agent A and curing agent B is 3:1; Described main agent A comprises each of the following weight percentages: Components: epoxy silicone resin 43.0%, dispersant 1.4%, conductive titanium dioxide 24.4%, graphene 0.02%, carbon nanotube 0.2%, defoamer 0.34%, leveling agent 0.44%, polyaniline 0.2%, Surface modifier 2.0%, diluent 28.0%.

[0029] The curing agent is alicyclic amine.

[0030] The epoxy silicone resin is Degussa's silicone modified epoxy resin.

[0031] The dispersant is BYK-161 of BYK Company in Germany; the conductive titanium dioxide is FT-300 produced by Ishihara.

[0032] The defoamer is BYK-051 of BYK Company of Germany; the leveling agent is BYK-354 of BYK Company of Germany.

[0033] The carbon nanotubes are TNHC from Chengdu Institute of Organic Chemistry, Chinese Academy of...

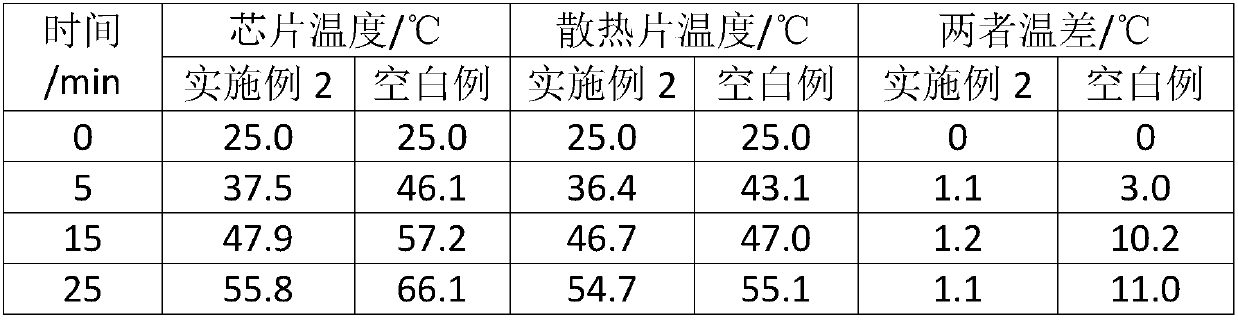

Embodiment 2

[0047]Polyaniline epoxy organosilicon graphene heat-dissipating and conductive static coating, comprises main agent A and curing agent B, and the weight ratio of described main agent A and curing agent B is 5:1; Described main agent A comprises each of the following weight percentages: Components: epoxy silicone resin 45.5%, dispersant 1.7%, conductive titanium dioxide 29.8%, graphene 0.03%, carbon nanotube 0.3%, defoamer 0.25%, leveling agent 0.25%, polyaniline 0.6%, Surface modifier 2.5%, diluent 19.07%.

[0048] The curing agent is phenalkamine.

[0049] The epoxy silicone resin is Degussa's silicone modified epoxy resin.

[0050] The dispersant is BYK-161 of BYK Company in Germany; the conductive titanium dioxide is FT-300 produced by Ishihara.

[0051] The defoamer is BYK-051 of BYK Company of Germany; the leveling agent is BYK-354 of BYK Company of Germany.

[0052] The carbon nanotubes are TNHC from Chengdu Institute of Organic Chemistry, Chinese Academy of Sciences....

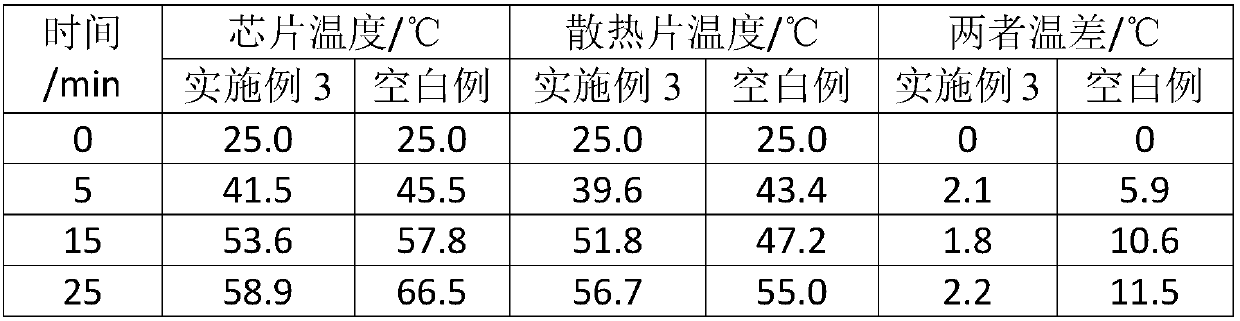

Embodiment 3

[0066] Polyaniline epoxy organosilicon graphene heat-dissipating and conductive electrostatic coating, comprises main agent A and curing agent B, and the weight ratio of described main agent A and curing agent B is 7:1; Described main agent A comprises each of following weight percent Components: epoxy silicone resin 48%, dispersant 2.0%, conductive titanium dioxide 30.0%, graphene 0.04%, carbon nanotube 0.4%, defoamer 0.3%, leveling agent 0.3%, polyaniline 0.6%, Surface modifier 3.0%, diluent 15.36%.

[0067] The curing agent is phenalkamine.

[0068] The epoxy silicone resin is Degussa's silicone modified epoxy resin.

[0069] The dispersant is BYK-161 of BYK Company in Germany; the conductive titanium dioxide is FT-300 produced by Ishihara.

[0070] The defoamer is BYK-051 of BYK Company of Germany; the leveling agent is BYK-354 of BYK Company of Germany.

[0071] The carbon nanotubes are TNHC from Chengdu Institute of Organic Chemistry, Chinese Academy of Sciences.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com