High radiant ceramic coating for heating furnace tube as well as preparation method and using method thereof

A ceramic coating and high-radiation technology, which is applied in the direction of reflection/signal coating, anti-corrosion coating, coating, etc., can solve the problems of short service life and high energy consumption, and achieve the effects of improving service life, increasing heat transfer, and avoiding local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

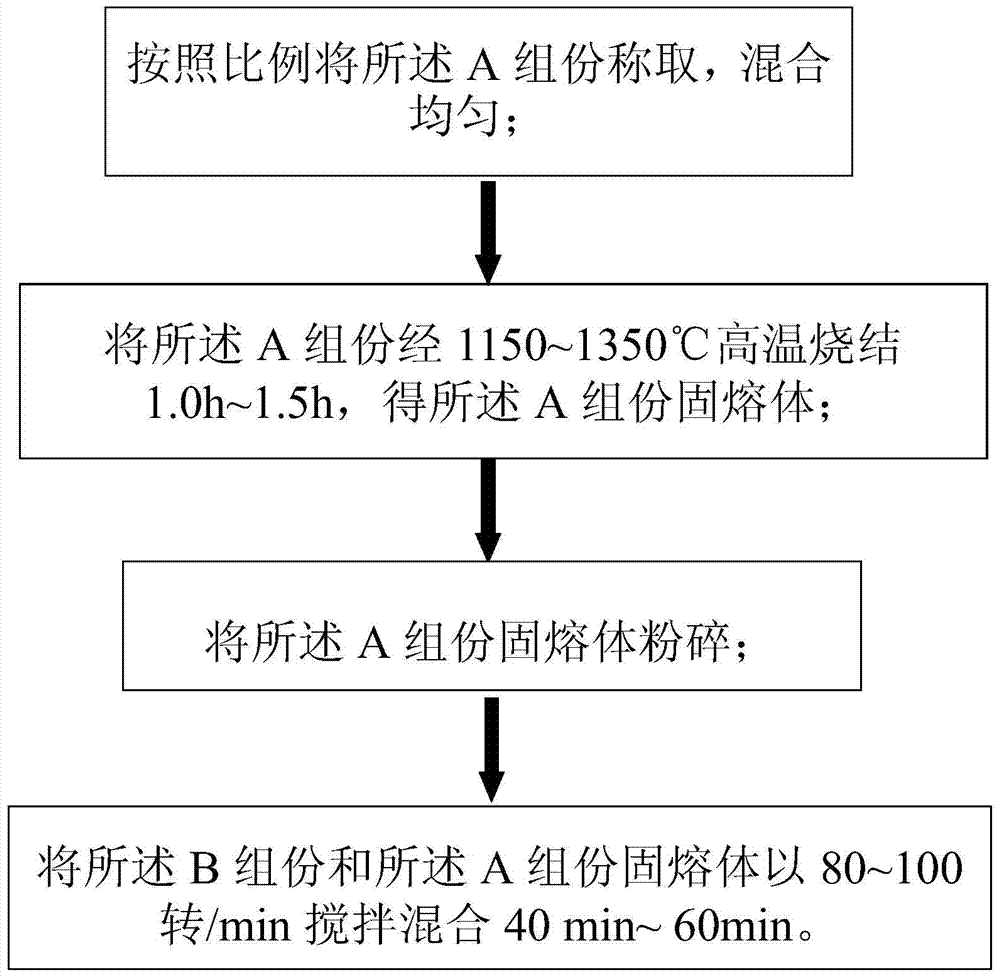

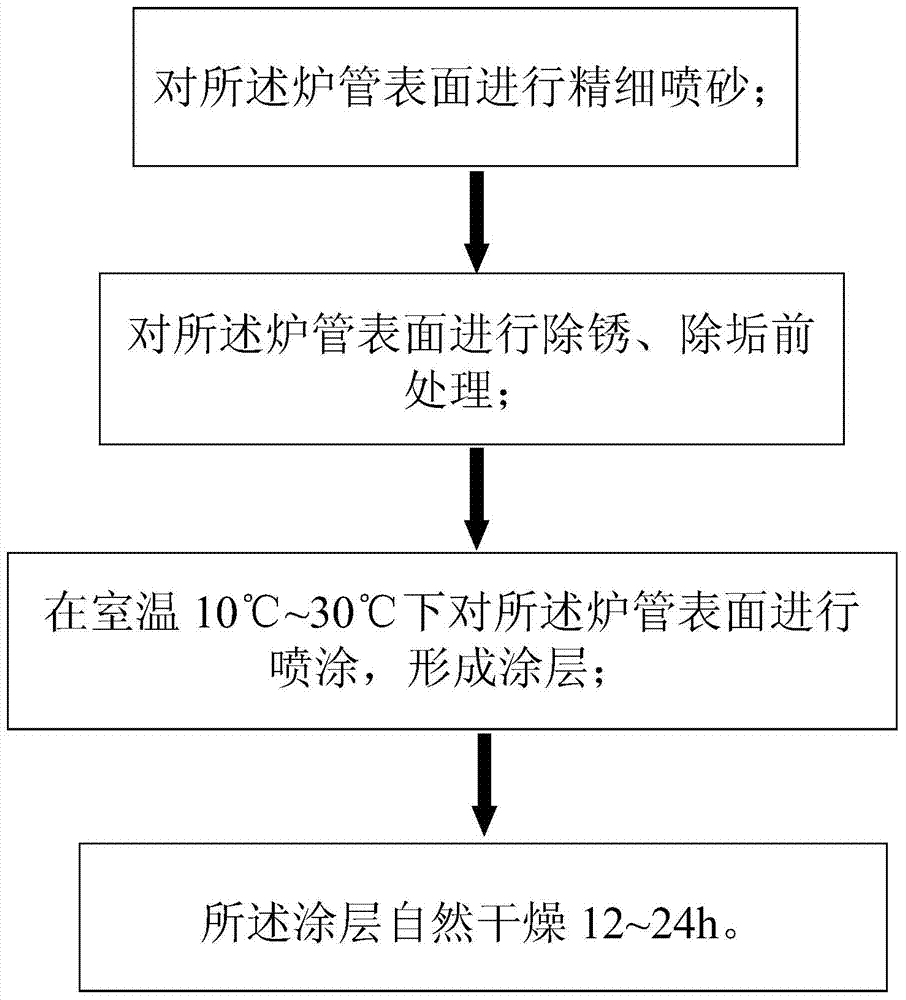

Method used

Image

Examples

Embodiment 1

[0036] The invention relates to a high-radiation ceramic coating for heating furnace tubes, which includes component A and component B, component A is a mixture of metal oxides, accounting for 30% of the total amount of the two components; component B is a high temperature resistant adhesive , accounting for 70% of the total.

[0037] Component A is specifically cobalt trioxide, aluminum oxide, manganese dioxide and copper oxide; cobalt trioxide accounts for 25% of the total amount of component A, and aluminum oxide accounts for 10% of the total amount of component A. Manganese dioxide accounts for 30% of the total amount of component A, and copper oxide accounts for 35% of the total amount of component A.

[0038] Component B specifically includes silica sol and additives, wherein silica sol is specifically a 20% aqueous solution of silicon dioxide, and additives specifically include thickeners, anti-sedimentation agents and wetting agents, and additives account for the total...

Embodiment 2

[0040] The invention relates to a high-radiation ceramic coating for heating furnace tubes, which includes component A and component B, component A is a mixture of metal oxides, accounting for 35% of the total amount of the two components; component B is a high temperature resistant adhesive , accounting for 65% of the total.

[0041] Component A is specifically cobalt trioxide, aluminum oxide, manganese dioxide and copper oxide; cobalt trioxide accounts for 35% of the total amount of component A, and aluminum oxide accounts for 20% of the total amount of component A. Manganese dioxide accounts for 20% of the total amount of component A, and copper oxide accounts for 25% of the total amount of component A.

[0042] Component B specifically includes silica sol and additives, wherein silica sol is specifically a 25% silicon dioxide aqueous solution, and additives specifically include thickeners, anti-sedimentation agents and wetting agents, and additives account for the total am...

Embodiment 3

[0044] The invention relates to a high-radiation ceramic coating for heating furnace tubes, which includes component A and component B, component A is a mixture of metal oxides, accounting for 32% of the total amount of the two components; component B is a high temperature resistant adhesive , accounting for 68% of the total.

[0045] Component A is specifically cobalt trioxide, aluminum oxide, manganese dioxide and copper oxide; cobalt trioxide accounts for 28% of the total amount of component A, and aluminum oxide accounts for 18% of the total amount of component A. Manganese dioxide accounts for 24% of the total amount of component A, and copper oxide accounts for 30% of the total amount of component A.

[0046] Component B specifically includes silica sol and additives, wherein silica sol is specifically a 22% silicon dioxide aqueous solution, and additives specifically include thickeners, anti-settling agents and wetting agents, and additives account for the total amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com