Preparation method of carbon fiber reinforced resin matrix composite rail vehicle head cover

A reinforced resin-based and composite material technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of mold sealing performance limitations, complex shape of the head cover, and unstable molding quality, so as to ensure the aerodynamic shape and reduce the The effect of process complexity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

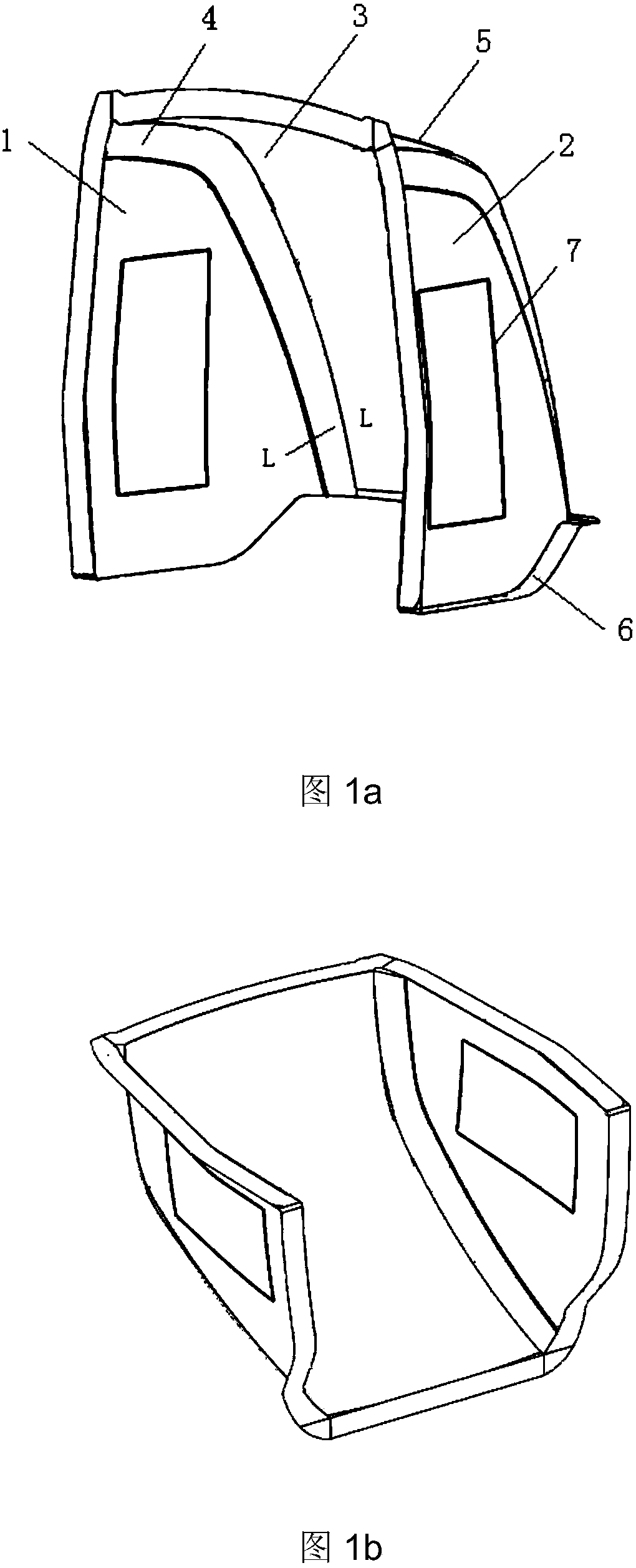

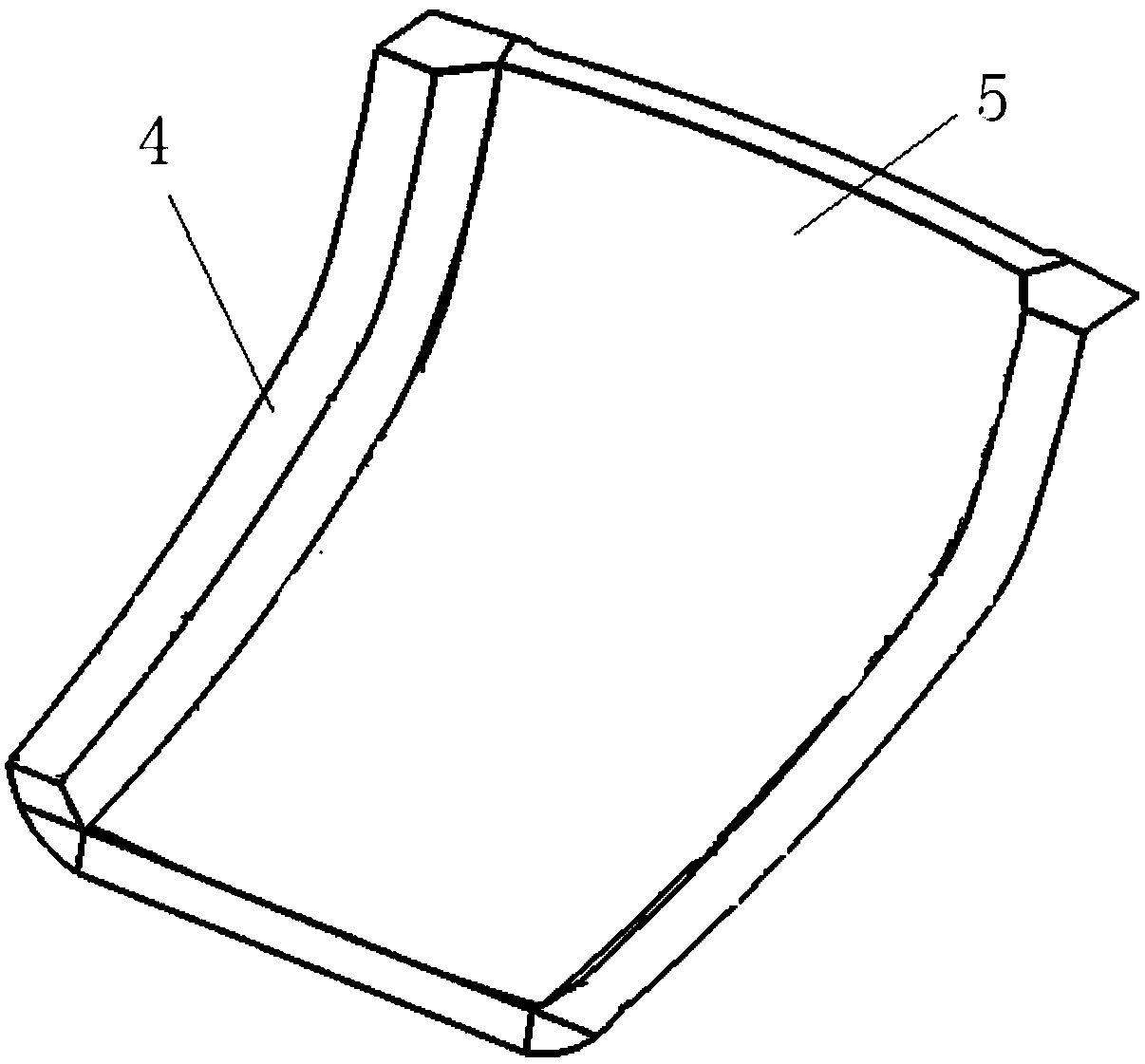

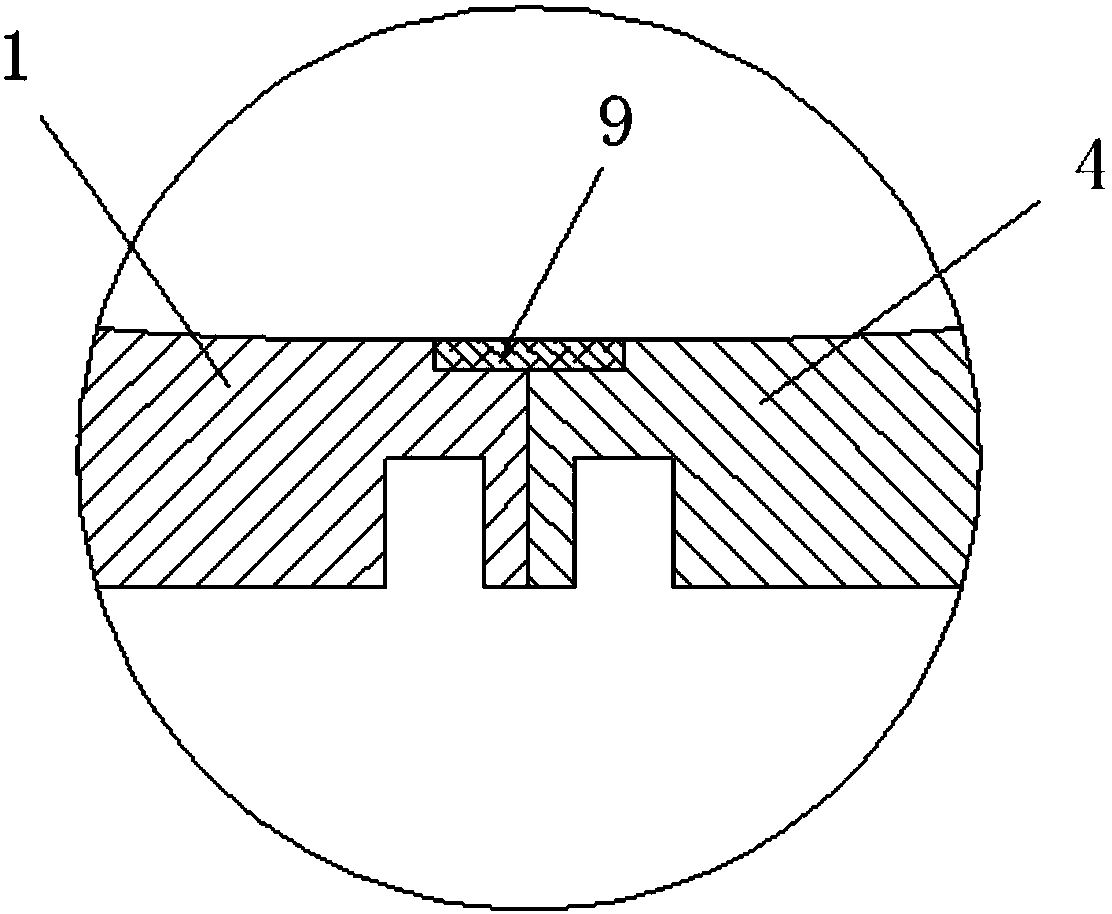

[0037] The preparation method of carbon fiber reinforced resin-based composite rail vehicle head cover in the present invention specifically comprises the following steps:

[0038] Step (1), using the above-mentioned hood combination mold to carry out layering and curing, the details are as follows:

[0039] (1) The carbon fiber stitch-bonded fabric is used for laying up the hood combination mold, and the specific laying method is as follows: N layers of four-axis carbon fiber stitch-bonded fabric and M layers of three-axis carbon fiber stitch-braided fabric are alternately laid. Layers, the total number of layers is an odd number, the first and last layers are both four-axis carbon fiber stitch-woven fabrics, and the weaving direction of the four-axis carbon fiber stitch-woven fabrics is: 0° / 90° / +45° / -45°, the weaving direction of the triaxial carbon fiber stitch-bonded fabric is: 0° / +45° / -45°.

[0040] Assuming that the total number of layers is 2n+1 layers, taking the n+1...

Embodiment 1

[0048] The example produced is a carbon fiber reinforced resin-based composite material rail transit vehicle head cover, which has many openings and complex shapes. The speed is 180km / h.

[0049] Step 1: Material Selection

[0050] Carbon fiber chooses carbon fiber stitched fabric, and the density of a single layer is 200g / m 2 The resin is epoxy-modified vinyl ester resin, the accelerator is cobalt naphthalate (1305), the catalyst is methyl ethyl ketone peroxide (M50), the flame retardant is organic phosphorus flame retardant, and the mass ratio is 100:0.3:0.3 : 3.5.

[0051] The second step is to use the hood composite mold to lay up layers, and the hood composite mold can be surface treated before laying up layers. A total of 7 layers, along the surface of the combined mold, followed by 1 layer of 4-axis braid, 2 layers of tri-axial braid, 1 layer of 4-axis braid, 2 layers of tri-axial braid, 1 layer of 4-axis braid material, where the triaxial (-45° / +45° / 0°) areal densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com