Abrasive preparation device, polishing system and working method

A technology for preparation devices and polishers, which is applied in the direction of feeding devices, grinding/polishing equipment, polishing compositions containing abrasives, etc., can solve the problems of lower production efficiency, less application, and difficulty in repeated use, so as to reduce waste Liquid discharge, improve economic benefits, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

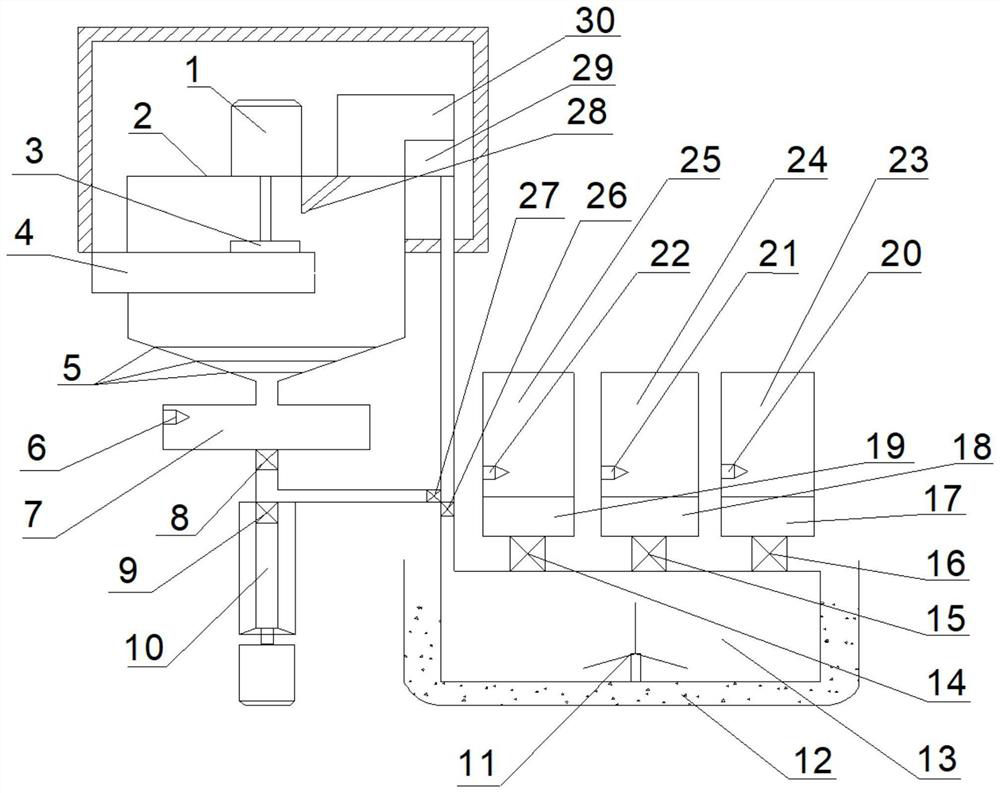

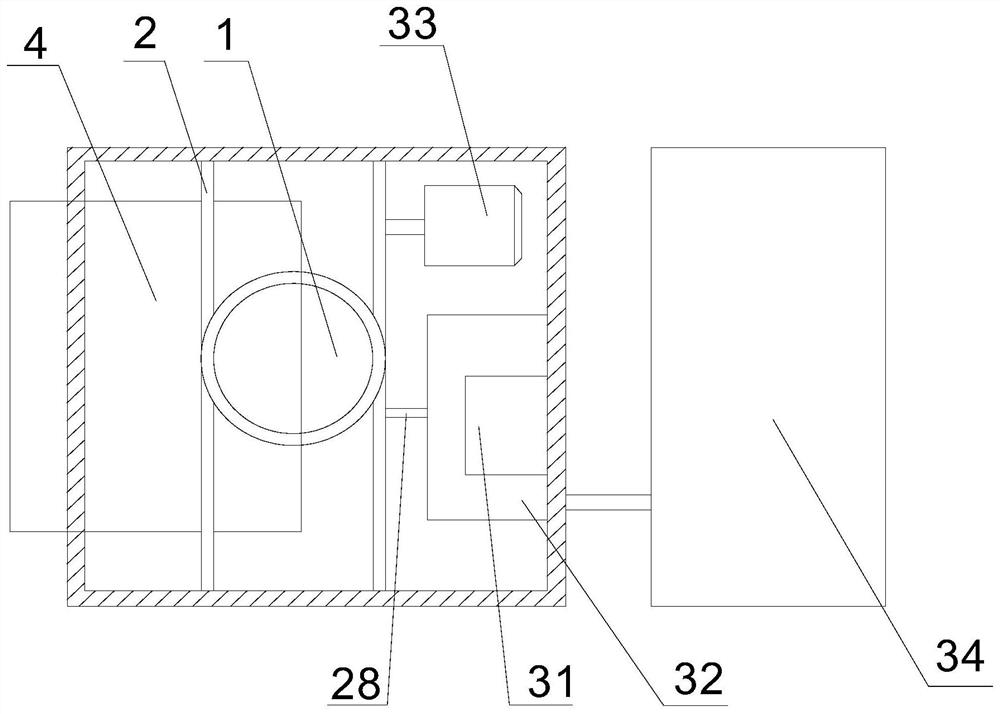

[0034] In an exemplary embodiment of the present invention, as Figure 1-Figure 3 As shown, an abrasive preparation device is given.

[0035] like figure 1 The shown abrasive preparation device 34 can utilize the hydrolysis and condensation reaction of the raw materials to generate nano-silica abrasive or nano-titanium dioxide abrasive, which can be connected to the polishing system to prepare and supply abrasives for the polishing system on site, and the prepared abrasives have sufficient hardness and good quality. Geometric shape and good particle size composition, sharp edges and corners, can meet the abrasive needs of polishing systems.

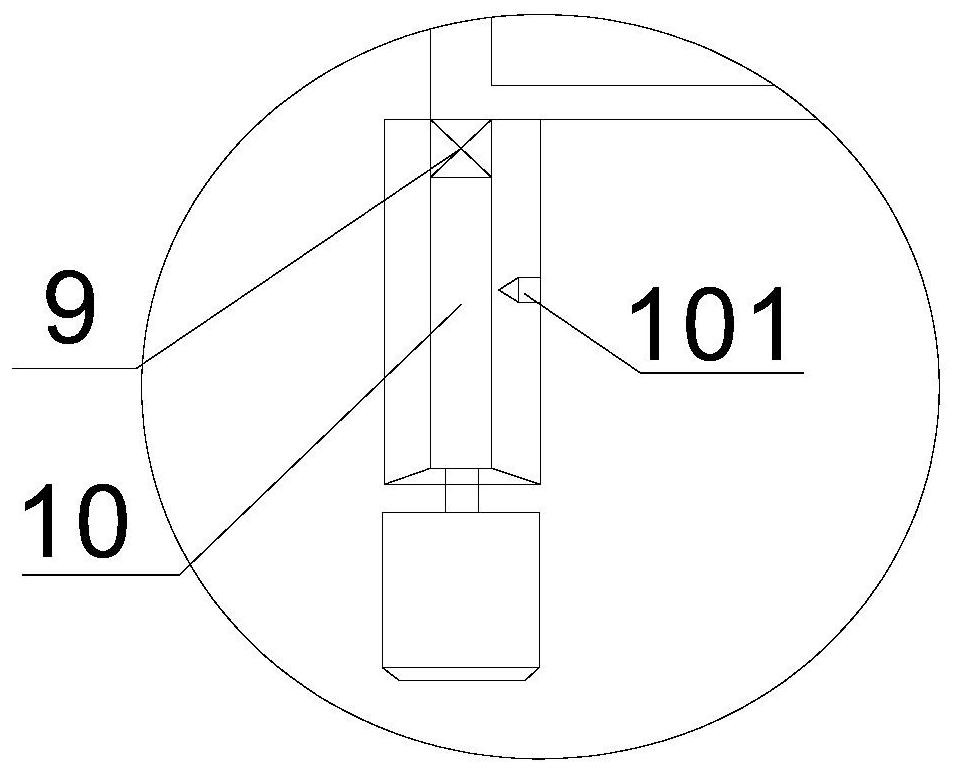

[0036] like figure 1 The abrasive preparation device 34 mainly includes a generating box 13, a stirring mechanism 11 and a plurality of feeding mechanisms. The feeding mechanisms all include a raw material tank, a raw material pump and a raw material valve. The outlet faces the generation box 13, and is used to put various kinds of raw...

Embodiment 2

[0054] In another exemplary embodiment of the present invention, as Figure 1-Figure 3 As shown, a polishing system is given.

[0055] like figure 1 The shown polishing system mainly includes an abrasive preparation device 34, a polishing workbench and a recovery device. The in-situ generation of nano-abrasives can be realized by using the abrasive preparation device 34 as described in Example 1, and the polishing workbench obtains abrasives and polishing liquid. It is output to the workpiece 4 for polishing, and the recycling device can realize the recycling of the polishing liquid, and at the same time realize the controllable particle size of the nano-abrasives. In the working process, polishing, recycling and preparation are continuously connected, work independently, and can work at the same time without affecting each other.

[0056] Specifically, as figure 1 , the polishing workbench includes a polishing pump 29, a polishing chamber and a liquid storage tank 7, the a...

Embodiment 3

[0067] In yet another embodiment of the present invention, as Figure 1-Figure 3 As shown, a working method of a polishing system is provided, utilizing the polishing system in Example 2.

[0068] Include the following steps:

[0069] The abrasive preparation device 34 conveys the polishing liquid with abrasive to the polishing pump 29 through the conveying pipeline, and the polishing pump 29 outputs the polishing liquid to the polishing station to polish the workpiece 4 on the polishing station;

[0070] The polishing chamber collects polishing liquid, abrasives and debris generated by polishing and transports them to the liquid storage tank 7 for temporary storage;

[0071] The recovery device obtains the mixed liquid in the liquid storage tank 7 for centrifugal separation, and sends the polishing liquid obtained after centrifugation to the polishing pump 29 for spraying.

[0072] Specifically, the pressure device 30 is included to control the spraying speed and dosage of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com