Method and device for processing polystyrene and graphene nanocomposite microstructure array

A technology of microstructure array and polystyrene microspheres, applied in microstructure devices, manufacturing microstructure devices, graphene, etc., can solve the problems of low production efficiency, high cost, long reaction time, etc., and improve the yield rate. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

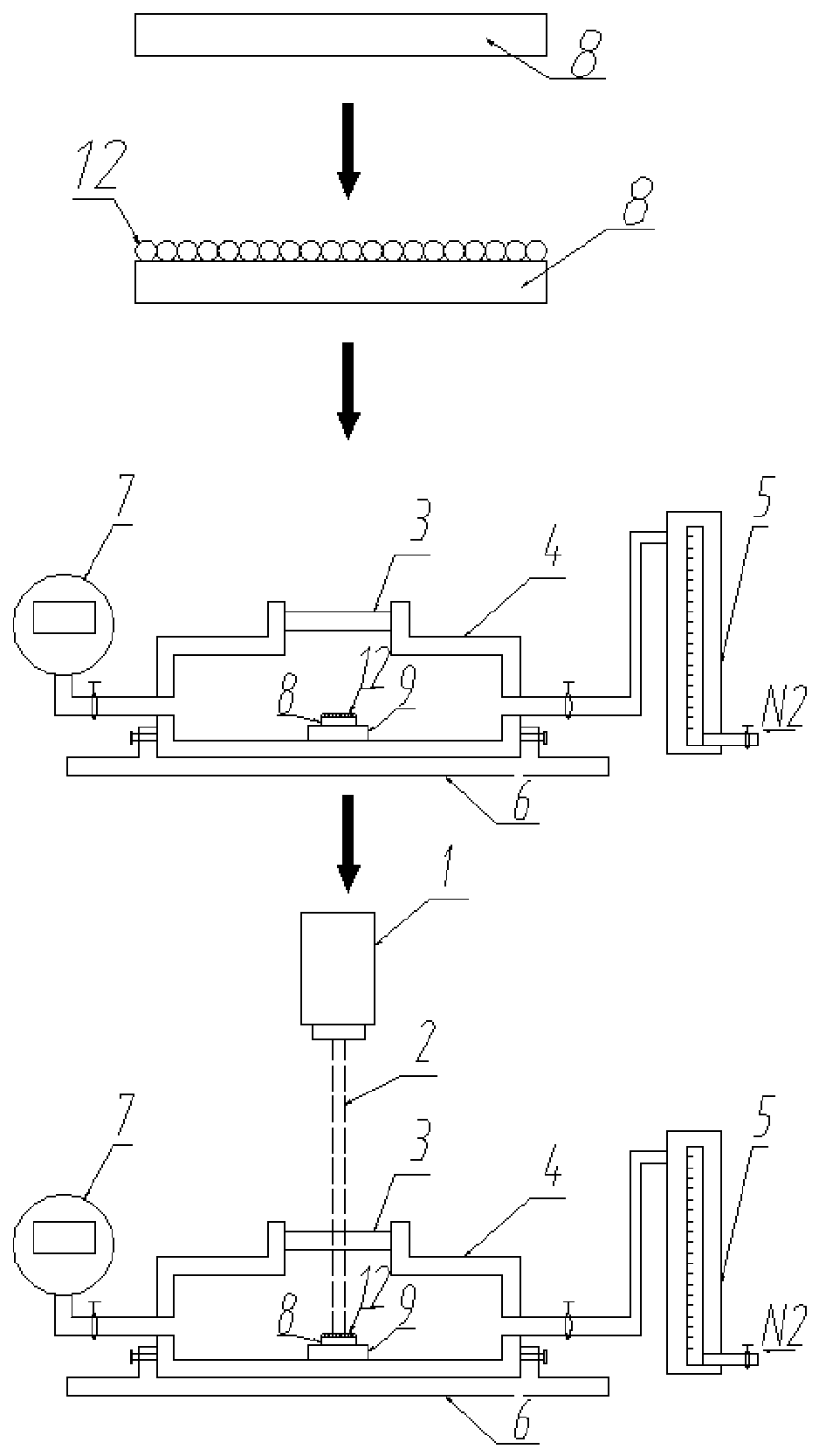

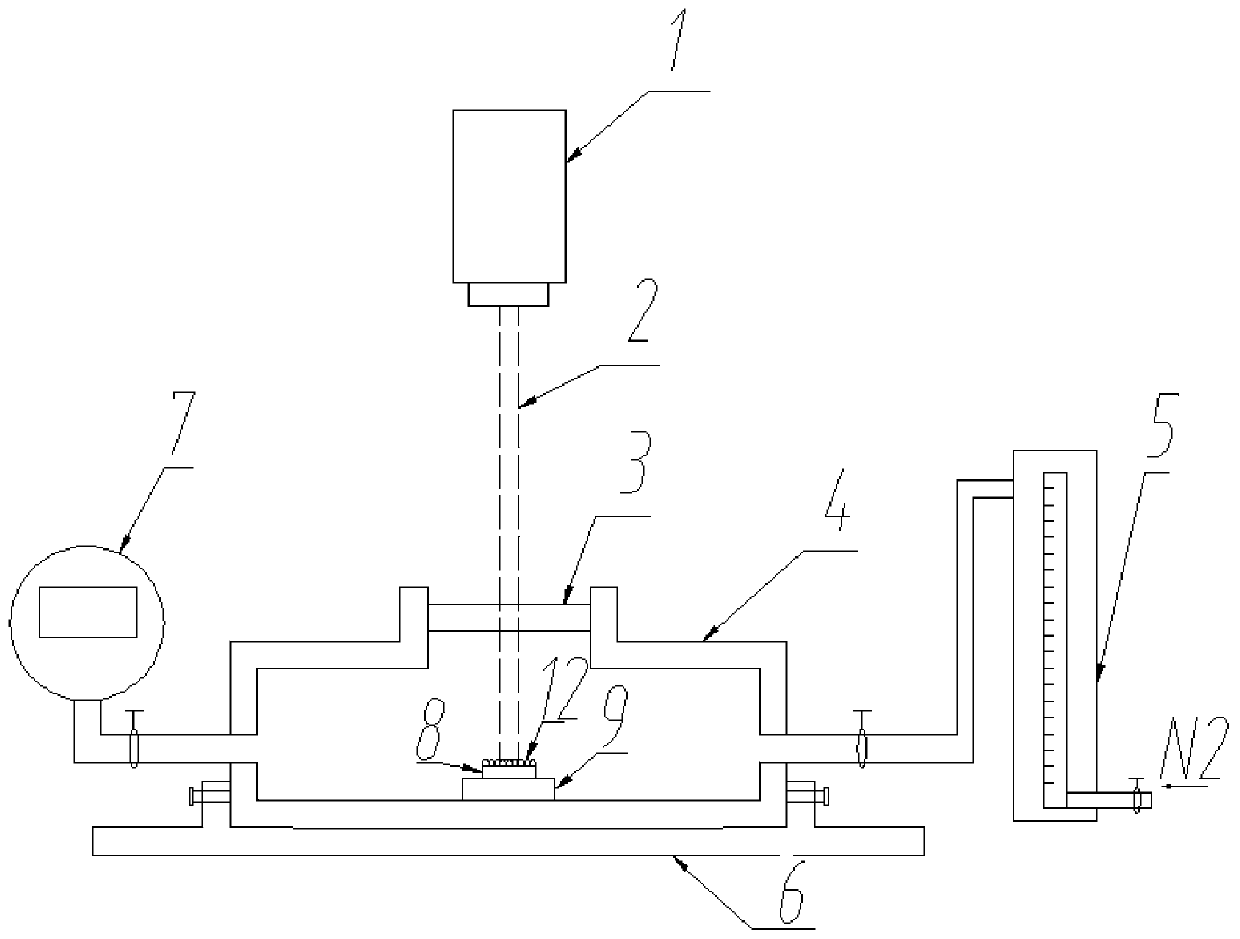

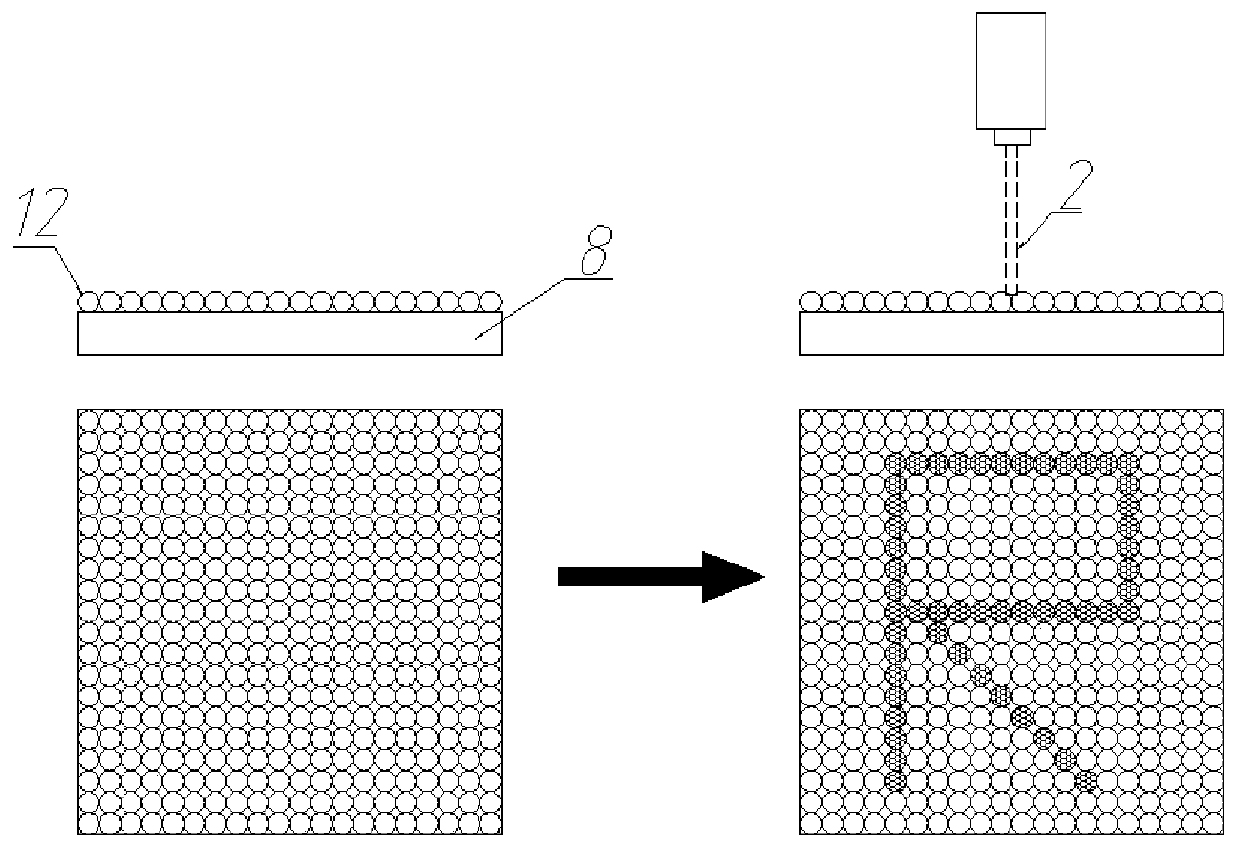

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0039] Such as Figure 1-5 As shown, 1, processing polystyrene, graphene nanocomposite microstructure array device, including laser generator 1, vacuum chamber 4, stage, ultraviolet filter 3 and gas flow control unit 5;

[0040] The object table is mounted on the bottom of the vacuum chamber 4 in a detachable and fixed manner, and the vacuum chamber 4 has open and closed passages;

[0041] The ultraviolet filter mirror 3 is installed in the vacuum cavity 4, and the laser generator 1 emits laser light and irradiates the object stage located in the vacuum chamber 4 through the ultraviolet filter lens 3, and the object stage is used to place the object to be processed. thing;

[0042] The gas flow control unit 5 is communicated with the vacuum chamber 4, and the gas flow control unit 5 is used to con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com