Material continuous or mixed conveying device and method for laser cladding

A conveying device and laser cladding technology, applied in metal material coating process, coating, etc., can solve the problems of manual mixed powder uniformity, powder feeder can not meet production requirements, and cannot change the ratio, etc., to achieve continuous conveying , avoid interruption, meet the effect of continuous conveying and mixed conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

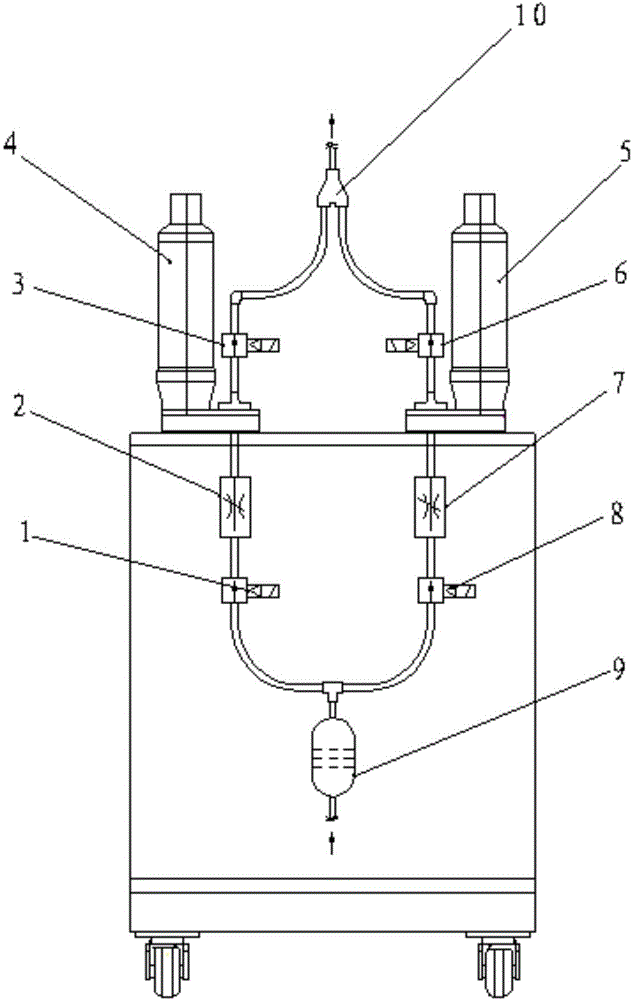

[0041] The continuous or mixed material conveying device for laser cladding provided by the embodiment of the present invention automatically completes the continuous conveying of powder according to the customized program:

[0042] see figure 1, first open the air filter 9, the first shut-off valve 1 and the second shut-off valve 3, and make the first gas flow meter 2 fully open, and spray the powder in the first silo 1 through the nozzle 10; when the first object When the position monitoring element (not shown in the figure) issues an indication, it means that the powder in the first silo 1 is about to be conveyed and the silo needs to be switched. At this time, the fourth shut-off valve 8 is opened, and the second gas flow meter 7 is opened to half of the normal flow rate; 10. The total flow of powder-carrying gas sprayed out is constant. Then open the rotating disk of the second material bin 5, start to rotate and discharge powder, and close the rotating disk of the firs...

Embodiment 2

[0045] The material continuous or mixed conveying device for laser cladding provided by the embodiment of the present invention automatically completes the mixing and conveying of two kinds of powders according to the required ratio according to the customized program. Powder and dynamic proportion mixing powder delivery.

[0046] 1) Mix and feed powder in fixed proportion: set the rotation speed of the turntable of the first silo 4 and the second silo 5 completely according to the required ratio of metal powder; set the first gas flow meter 2 and the second gas flow Count 7 as half of the normal value. Finally, all the stop valves, gas flow meters and air filter 9 are opened, and the metal powder is sent out according to the set flow rate, and then converged to the nozzle 10 to form the required ratio of alloy powder, which realizes the mixed delivery of metal powder in a fixed ratio .

[0047] 2) Dynamic proportional mixing powder feeding: first send the base material powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com