Batching, mixing and packaging all-in-one machine

An all-in-one machine and material mixing technology, which is applied in the fields of batching, packaging all-in-one machines, and material mixing, can solve the problems that functional units cannot be used alone, high basic investment in plant equipment, and affect measurement accuracy, etc., and achieve simple structure, small plant investment, The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

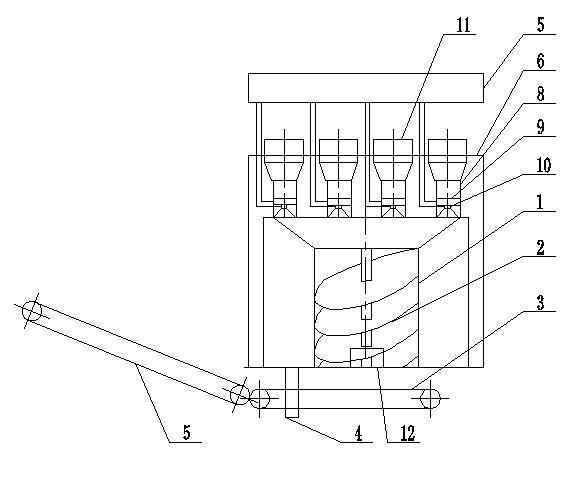

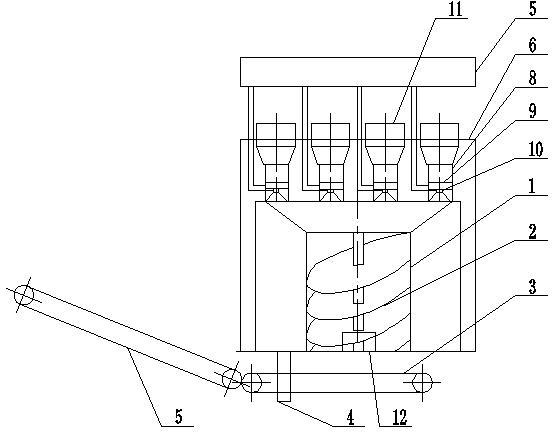

[0019] as attached figure 1 Shown: the all-in-one batching, mixing and packaging machine of the present invention includes a quantitative dosing device, a mixing cylinder 1 is installed below the quantitative dosing device, a screw mixer 2 is installed inside the mixing cylinder, and the mixing A package conveyor 3 is installed below the cylinder, and a bag sewing machine 4 is arranged on the package conveyor, and the package conveyor is connected to a finished product conveyor 5 .

Embodiment 2

[0021] In the batching, mixing and packaging all-in-one machine, the quantitative batching device includes a single-material bin frame 6, and a group of single-material bins 7 are installed on the single-material bin frame, each of the A discharge pipe 8 is installed below the single-material silo, and a discharge control valve 9 and a meter 10 are successively installed on the discharge pipe, and the discharge control valve and the meter are all connected to the PLC control system 11.

Embodiment 3

[0023] In the batching, mixing and packaging machine, the lower part of the mixing cylinder has a viewing window 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com