Metering control system, concrete spraying machine and metering control method

A technology of control system and control method, which is applied in flow control of electric devices, flow control of auxiliary non-electric power, mechanical equipment, etc., can solve problems such as high cost, high cost of metering control system, and increased cost of metering control system. Achieve the effect of low cost, reduce cost and ensure adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

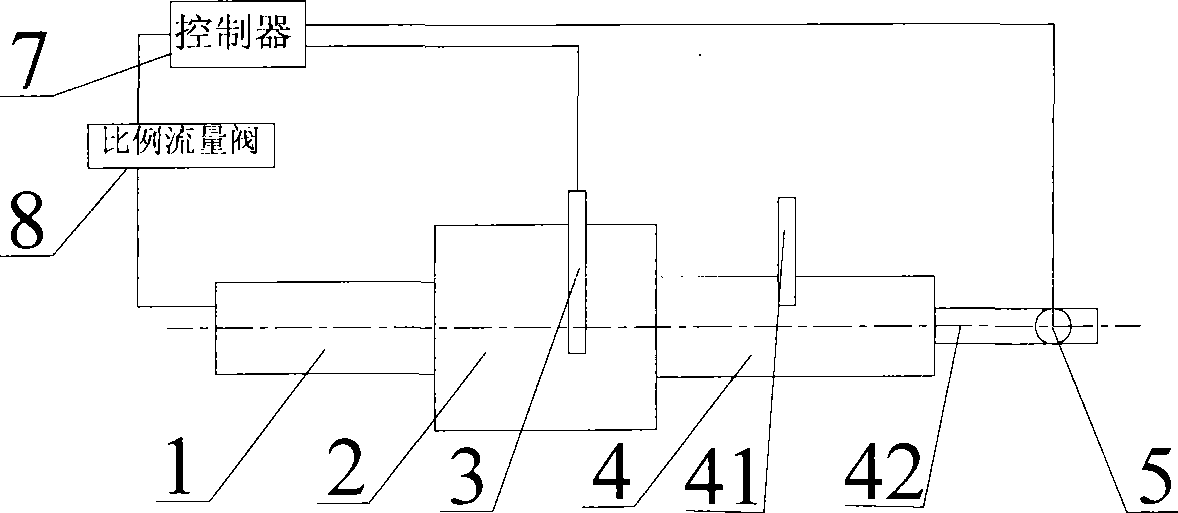

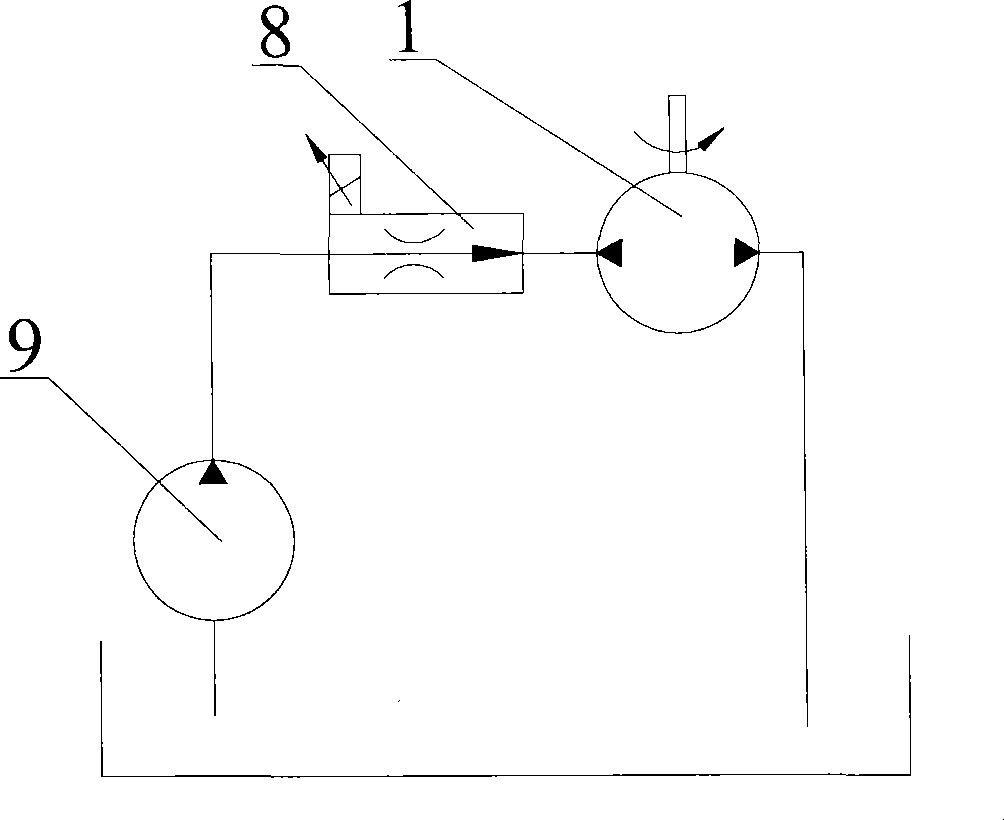

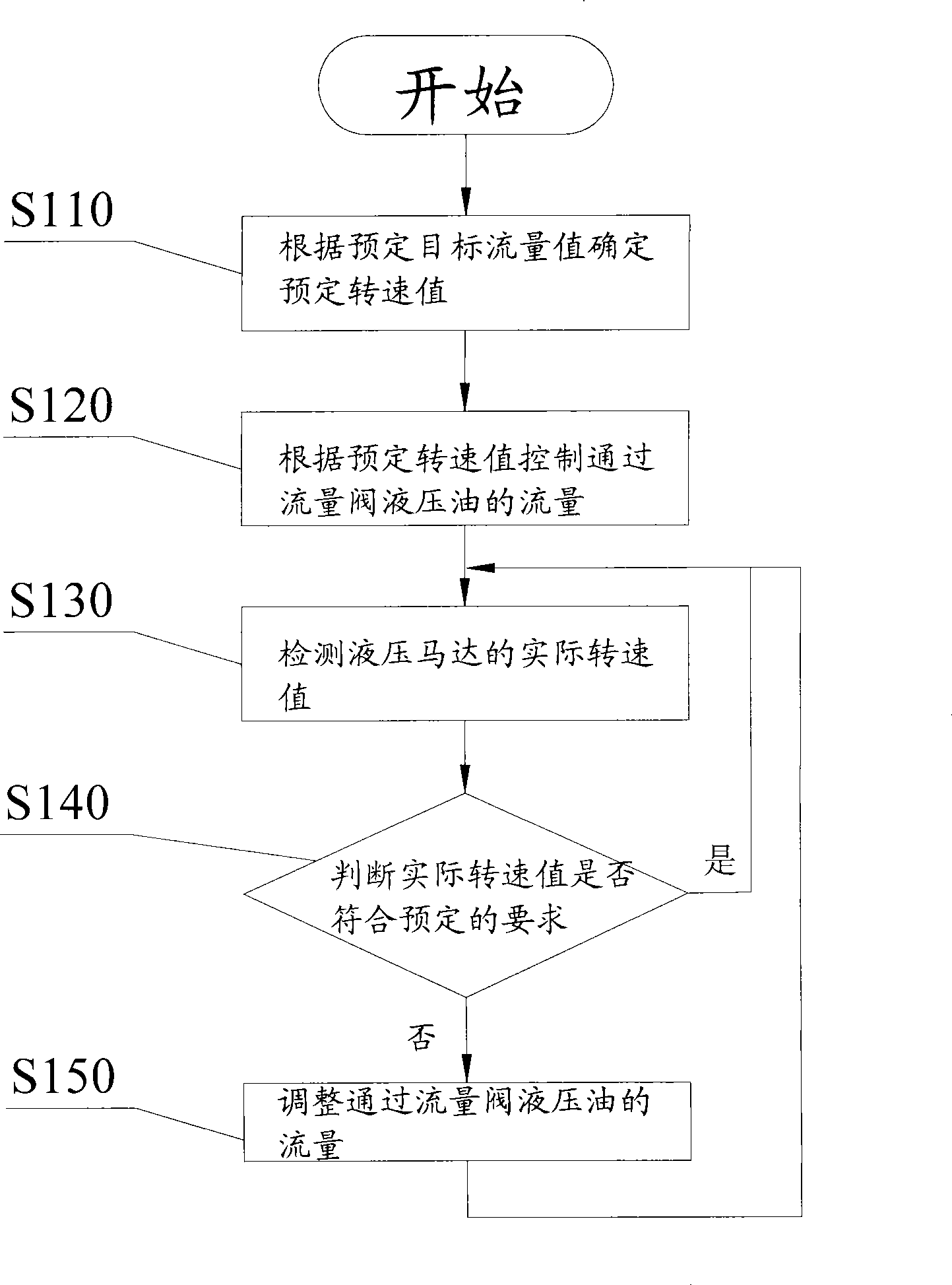

[0051] The working process of the metering control system provided by Embodiment 1 is: according to the flow rate of the concrete mixture delivered by the concrete wet spraying machine pumping system, determine the target flow value of the external additive at the output port 42 of the metering pump 4; then determine the hydraulic motor according to the target flow value 1, the predetermined rotational speed value is preset in the controller 7, and the controller 7 calculates the input current of the proportional flow valve 8 according to the predetermined rotational speed value. According to the calculation result, the controller 7 controls the input current of the proportional flow valve 8, so that the proportional flow valve 8 maintains the corresponding opening, the hydraulic system supplies oil to the hydraulic motor 1 with the corresponding flow, and the hydraulic motor 1 rotates at a predetermined speed value, so that the metering The flow rate of the external additive a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com