Pneumatic conveying system for spraying calcium in stokehole

The technology of a pneumatic conveying system and a screw conveyor is applied in the field of material conveying of gas-solid two-phase flow, which can solve the problems of affecting the desulfurization effect, waste of desulfurizing agent, uneven feeding, etc. Uniform feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

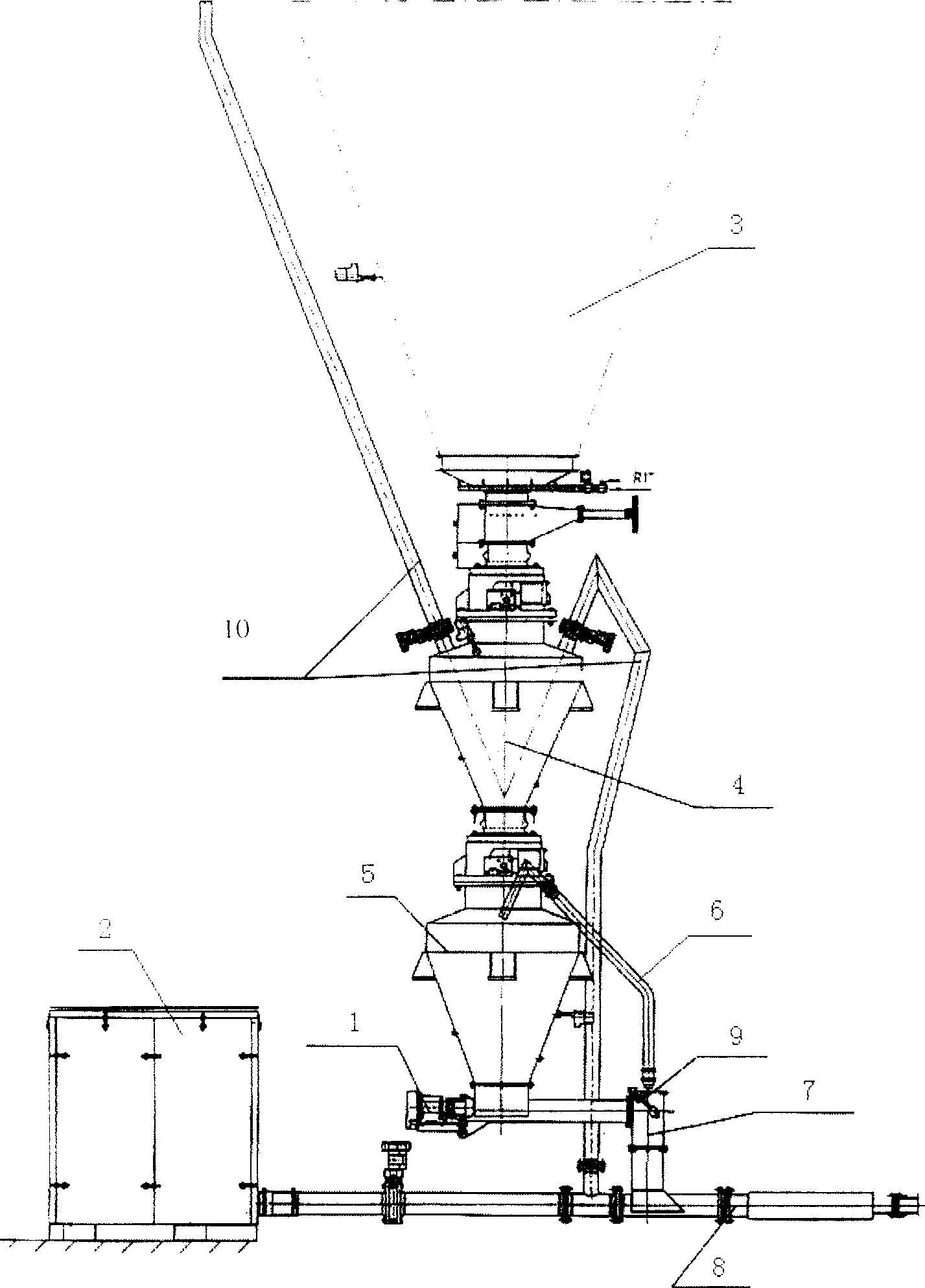

[0024] like figure 1 As shown, the pneumatic conveying system for calcium spraying in front of the furnace of the present invention is composed of a silo 3, an upper hopper 4, a lower hopper 5, a screw conveyor 1 and a fan 2, and the screw conveyor 1 has a feed inlet and an outlet The hopper, the fan 2 has an air outlet, wherein the upper hopper 4 is arranged above the lower hopper 5, the upper hopper 4 communicates with the lower hopper 5, and the upper hopper 4 communicates with the lower hopper 5. The silo 3 is arranged above the upper hopper 4, the silo 3 communicates with the upper hopper 4, the lower hopper 5 has a lower hopper outlet, and the lower hopper outlet is connected to the upper hopper. The feed port of the screw conveyor 1 is connected, the discharge port of the screw conveyor 1 is connected with a vertically arranged drop pipe 7 through a horizontal conveying pipe, and the air outlet of the fan 2 is connected with an air pipe One end of the air pipe is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com