Quantitative conveying system for wood flour

A conveying system and wood powder technology, applied in block/powder supply/distribution, combustion method, combustion equipment, etc., can solve the problems of fan blade damage, increase maintenance rate, block powder conveying pipe, etc. The effect of wind conveying, reducing maintenance rate, and uniform wood powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

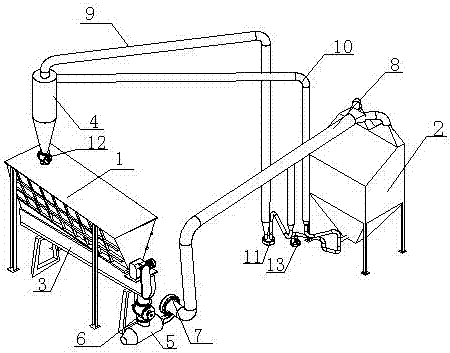

[0014] A wood powder quantitative conveying system includes a storage bin 1, a feed bin 2, an oblique screw 3, a separator 4 and a venturi 5. The storage bin 1 has a rectangular structure, and the lower end of the storage bin 1 is open. The oblique screw 3 is installed obliquely at the bottom opening of the storage bin 1, a flap valve 6 is connected below the high end of the oblique screw 2, the separator 4 is installed at the upper end of the storage bin 1, and the separator 4 is located at the upper end of the storage bin 1. Above the lower end of the screw 3, a blower 7 is connected to the rear end of the venturi 5, the air inlet of the blower 7 is connected to the upper end of the feed bin 2 through a suction pipe 8, and the upper end of the separator 4 passes through a smoke exhaust pipe 9 It is connected to the suction pipe 8, a feed pipe 10 is provided on the side wall of the separator 4, the other end of the feed pipe 10 is connected to the lower end of the feed bin 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com