Material arrangement machine with inclined tray

A technology of a material sorting machine and a swash plate, applied in the field of machinery, can solve the problems that the packaged objects cannot be transported to the packaging mechanism, the packaged objects cannot be repeatedly put into production, and the production cost increases, and achieves strong versatility, convenient operation, and reduced equipment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

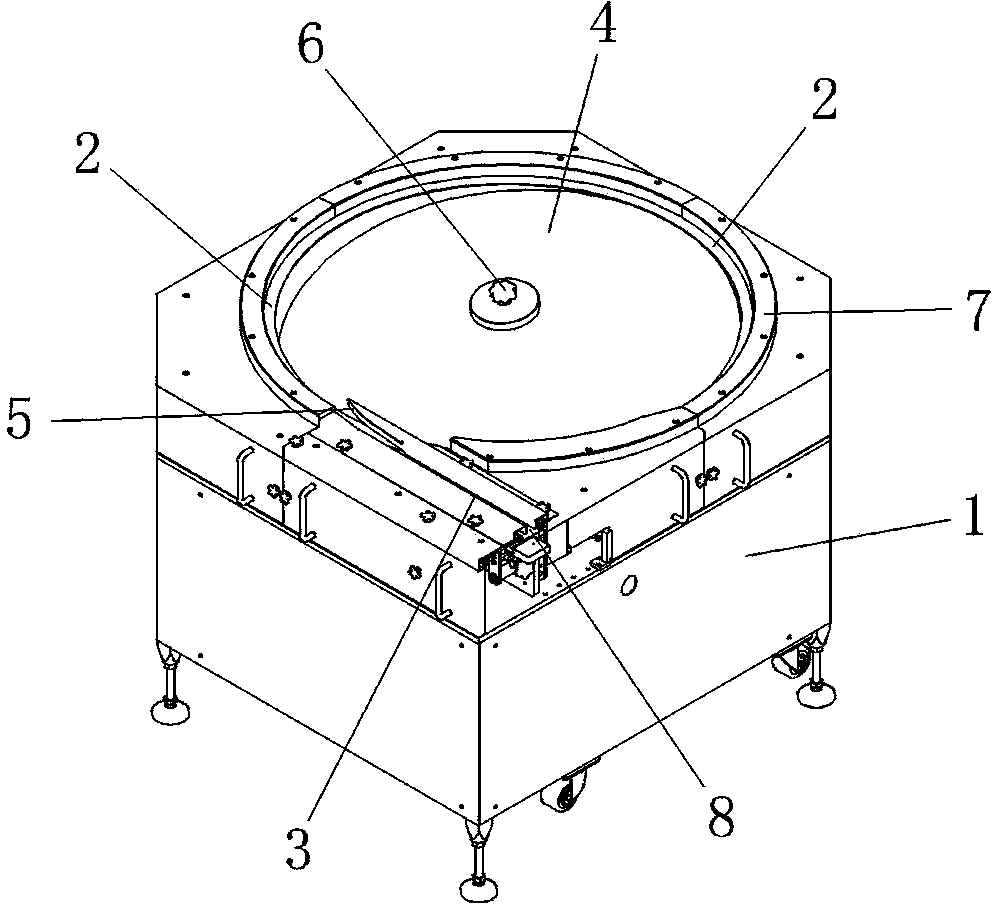

[0020] Such as figure 1 The swash plate sorting machine shown includes a frame 1 and a circular material pot 2 embedded in the top of the frame 1. A motor 1 for driving the material pot 2 to rotate circumferentially is provided in the frame 1. The top of the frame 1 A conveying line 3 communicating with the material pot 2 is provided, and the conveying line 3 is strip-shaped and tangent to the material pot 2 . In this embodiment, a rotating shaft is provided at the center of the material pot 2, and a motor 2 for driving the rotating shaft to rotate in the same direction as the material pot 2 is provided under the frame 1, and the material pot 2 is set on the rotating shaft. The tray 4 and the tray 4 are arranged obliquely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com