Lubricating oil focus cycle utilization system for preventing oil pump suction

A lubricating oil and oil pump technology, applied in the field of lubricating oil circulation system, can solve problems such as increasing maintenance costs, affecting lubrication effect, and affecting the service life of oil pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

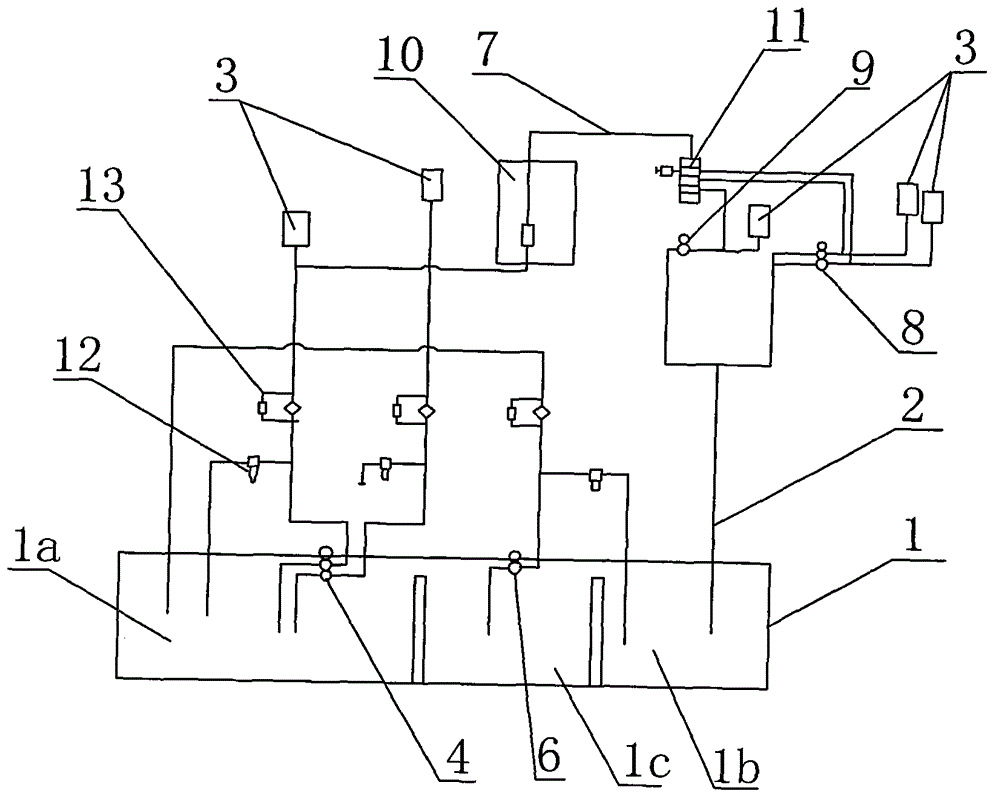

[0012] The lubricating oil centralized recycling system for preventing oil pump suction of the present invention includes an oil tank 1, an oil pipe 2, a double gear pump 4 that sends the lubricating oil from the clean chamber 1a of the oil tank 1 to the lubrication point 3, and transfers the lubricating oil to the lubricating point 3. The oil is sent back to the oil return pump 5 in the dirty oil chamber 1b of the oil tank, and the lubricating oil deposited in the dirty oil chamber 1b of the oil tank is pumped into the circulating gear pump 6 in the clean chamber 1a, and a preventive oil pipe is installed on the oil pipe from the double gear pump 4 to the lubrication point The suction branch 7 and the anti-cavitation branch 7 are connected to the double oil return pump 8 and the single oil return pump 9 . A speed regulating valve 10 is also set on the suction branch 7, and the speed regulating valve 10 is connected with a progressive distributor 11, and the progressive distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com