Hydrophobic film and preparation method thereof

A thin film preparation and hydrophobic technology, applied in the direction of coating, etc., can solve the problems of high construction difficulty and general coating film quality, and achieve the effects of precise control of raw material usage, reasonable design, reduced labor costs and low expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

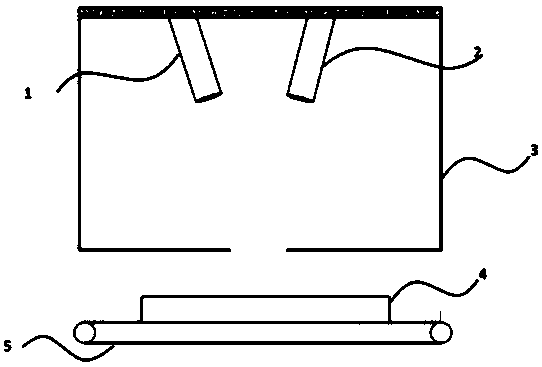

Image

Examples

Embodiment

[0016] 1. Add the raw material dimethyldichlorosilane of the evaporation source A, adjust the temperature to promote the gasification of the raw material, and carry out the gasification operation of the raw material trichloromethylsilane of the evaporation source B at the same time.

[0017] 2. Adjust the air flow, and adjust the ratio of evaporation source A to evaporation source B to be 1:1.

[0018] 3. During the operation of the conveyor belt, put in the glass to start the coating operation, and adjust the speed of the conveyor belt to 20mm / s.

[0019] 4. The evaporated gas is deposited on the glass surface to form a thin film, and the thin film is tested, and the contact angle and friction resistance are tested.

[0020] Compared with the prior art, the present invention has the advantages that: the present invention adopts the co-deposition method to prepare the hydrophobic film, first of all, it can quickly and efficiently prepare a high-quality hydrophobic film; second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com